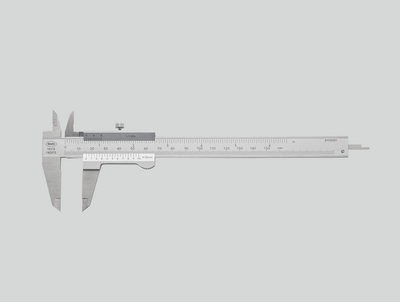

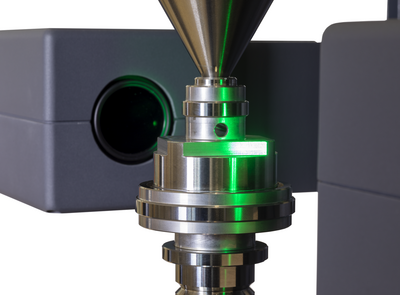

The accuracy of these dimensional measuring instruments must be periodically checked to ensure that they are correctly performing the job for which they are intended. And whether you are a small shop or large one, more and more requirements are being set to document this performance and ensure that all gaging is under control.

In fact, accepted standards call for all manufacturing operations to calibrate all inspection, measuring, and test equipment and devices that can affect product quality at prescribed intervals, or prior to use, against certified equipment having a known valid relationship to nationally recognized standards. Or, if there are no predetermined standards, then the basis used for calibration must be documented.

Maintaining and checking the performance of hundreds or thousands of gages can be a costly proposition, whether you buy the equipment and hire the people to do it internally or send the gages to an outside calibration service to perform the checking for you. For smaller machine shops the most economical approach is usually to hire a calibration service to do this verification for you.

But where is the break point that determines when to document gaging performance internally or have it sent out to a calibration service? And is there a hybrid option: using internal resources for some of the more basic instruments while using an external service for others, perhaps high-performance items?

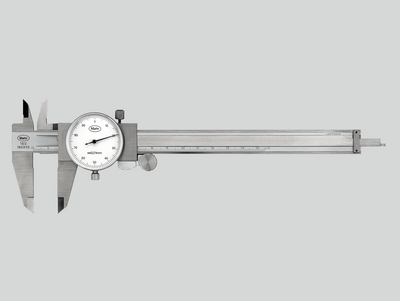

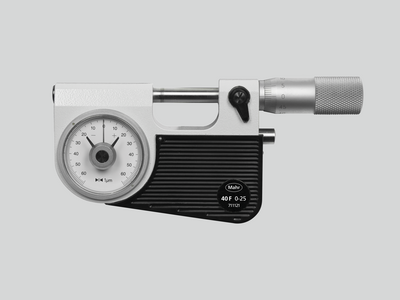

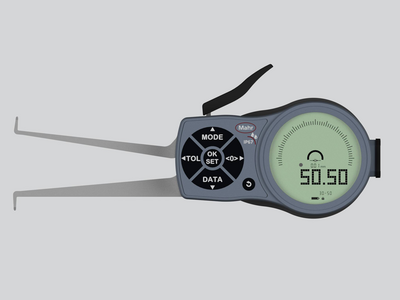

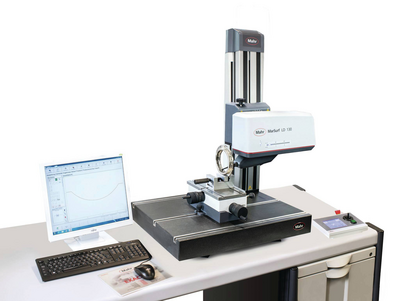

If you already have a quality control department that is responsible for checking parts, there is the potential for doing the internal checking and calibration of some of your own basic measuring tools—such as calipers, micrometers and dial and test indicators. You may already have the standards and equipment to do much of this calibration work, such as a set of gage blocks.

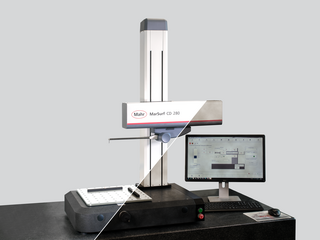

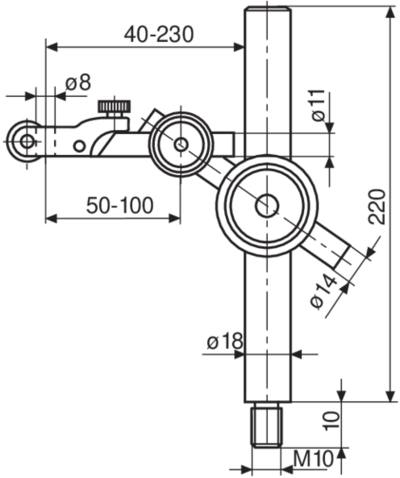

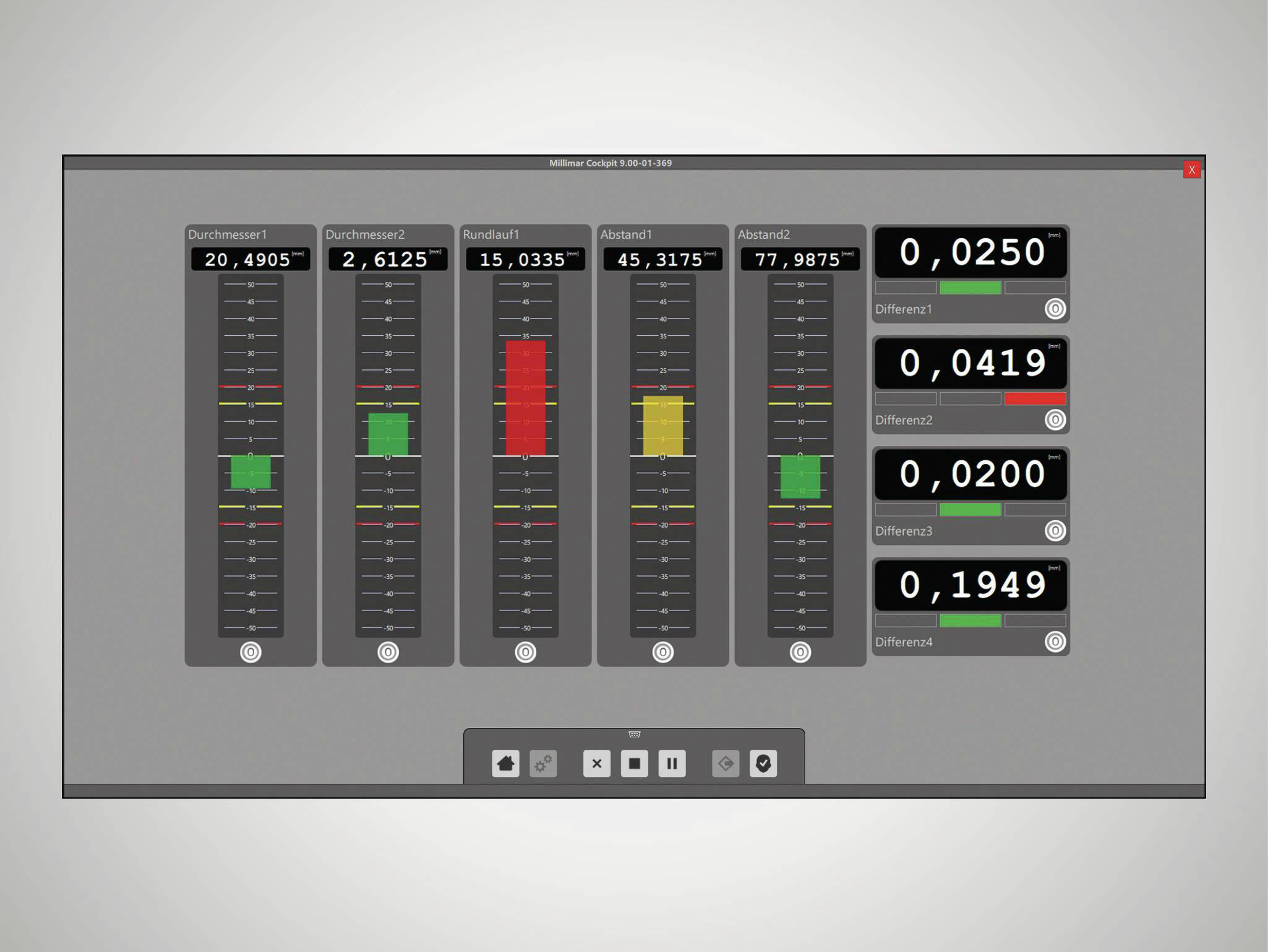

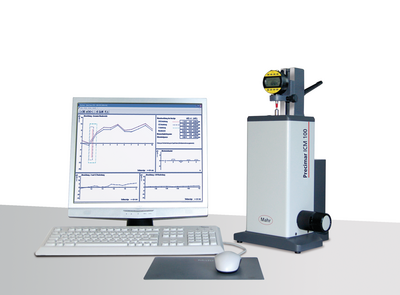

Being universal, gage blocks could be used for all of these items though a bit cumbersome for checking the dial, test and digital indicators. This is because of the number of data points needed and the handling of all the gage blocks. However, for about the same price as a good set of gage blocks, the investment in a dial indicator calibrator would cover all of the basic hand tools in your operation. With your set of blocks and the calibrator, you would have all the tools needed to consider bringing the outsourced items in house. It's a decision to think about with all the time and handling associated with sending your tools out.

But as the standards point out, the items under test have to be verified using certified equipment having a traceable relationship to a nationally recognized standard. So in this case the gage block set might be the only item that would have to be sent out for periodic calibration to ensure the blocks are at their prescribed accuracy. Thus, your gage block sets become the traceable standards required to meet the requirements for documenting the performance of all your gaging instruments.

Besides having the traceable standard to do the work internally, you must have and show that you have procedures in place, and that they are followed for the calibration of the instruments. This is where the real work comes in, at least initially. You must be able to document that you have the traceable tools, trained operators and the procedures in place to do your own instrument verification. There is also work in establishing your sources of error in the measurement process. No small tasks for sure, but you probably have procedures in place now for part inspections and other processes. So you already know how to comply with these types of requirements.

With the proper standards, instruments, people, environment, and documentation, you have all the tools necessary to get your dimensional measuring instruments periodically checked for their performance, and ensure they are accurately performing the job for which they are intended: which helps you fulfill the goal of meeting production requirements in the most cost-effective way.

For about the same price as a good set of gage blocks, the investment in a dial indicator calibrator would cover all the basic hand tools in your operation. With your set of blocks and the calibrator, you would have all the tools needed to consider bringing the outsourced items in house. It's a decision to think about with all the time and handling associated with sending your tools out.