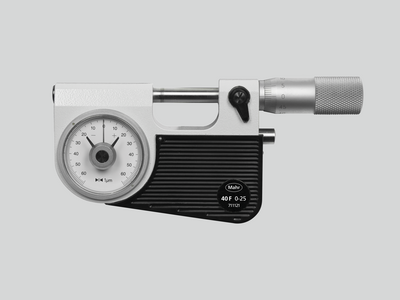

But despite the clear superiority of electronic indicators in terms of higher resolutions, better accuracy, and usefulness in statistical process control and data collection systems, mechanical indicators retained other advantages and continued to be specified by many users. Today however, while neither type is "better" than the other, and the choice depends upon the application and the user's personal preference, digital finally seems to be gaining the upper hand.

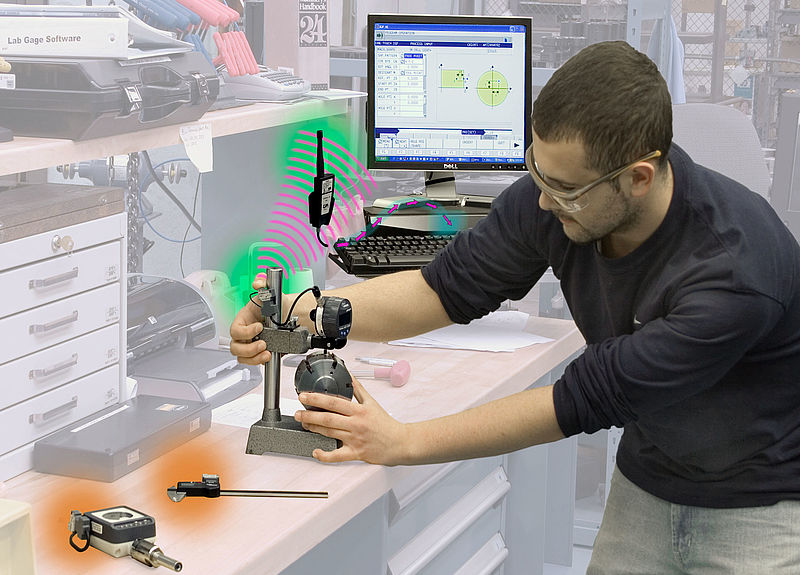

The clearest advantage of digital indicators is in their use for data collection in process control. Digital indicators can output measurements directly, usually as an actual value, e.g., 20.00 mm, to printers or SPC programs, with no operator errors in reading or recording. The operator only has to position the workpiece and press a button: he needn't even read the measurement. And within the past 5 years or so, this process has gone wireless, meaning that the tangle of cables has been eliminated, and gages have become much more portable.

With dial indicators, the operator must interpret the pointer's position to read the measurement, then he must record it—generally by hand—and finally the data must be keyed into a computer. That makes three steps during which errors can and frequently do occur. In any situation where data must be entered into a computer system, digital indicators are the only way to go.

At one point, the cost of digital indicators was significantly higher than dial indicators, but today basic digital indicators are very competitive with high quality dial indicators, and provide additional standard features such as auto-zeroing, actual values, in/mm switchable reporting, reversal of measuring direction, and data output. A lot of value is now affordable in what was a premium product 30 years ago.

However, even with the cost benefit gone, there still is something to be said for mechanical dial indicators. In many ways, the human brain is like an analog device, and it can often gather more information, more quickly, from an analog readout. I have seen QC inspectors make consistently accurate go/no-go readings with dial indicators even before the pointer has stopped moving! They can tell at a glance approximately where the pointer will stop, and in many applications, that is close enough. Digital displays don't give you the option of approximating. When a digital device is flickering between six and seven, all of the elements in an LCD display may be lit, appearing as an eight.

Skilled operators can also "split grads" with dial indicators, i.e., resolve the pointer's position to an accuracy of about one-fifth of the gage's stated minimum graduation value. And analog dials enable the machinist to observe the direction his process is headed. If reading #1 indicates 1/5 of a grad over zero, reading #2 is precisely zero, and reading #3 is 1/5 of a grad below zero, the user may be able to draw valuable conclusions about the condition of his tool. In other words, dials can provide more information than simply the dimensional measurement. An early digital readout would have read zero in all three cases, depriving the user of this additional information.

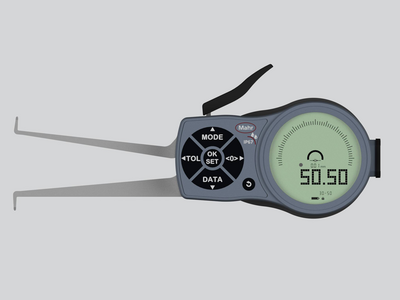

On the other hand, today's digital indicators are capable of resolutions that were once reserved for bench amplifiers. Now that "fifth of a grad" is another digit on the indicator, and that process change can be observed (assuming, of course, that the gage is up to the higher resolution of the display). In addition, many of today's digital indicators have some form of supplemental analog display. These electronic emulations of analog performance serve to eliminate some of the cognitive disadvantages of digital displays, and make digital indicators "user-friendly" in that they start to give the impression of direction and of how far over or under the part tolerance the item being inspected is.

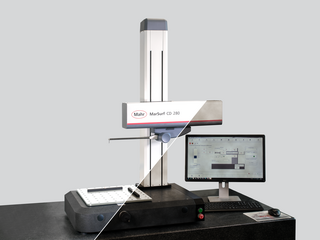

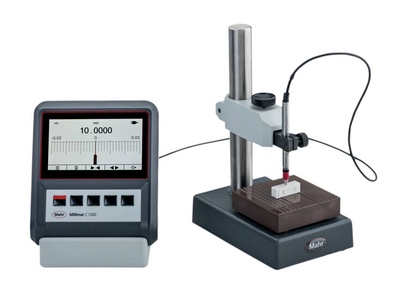

In fact, many digital indicators are becoming so powerful that they are taking on the performance and features of bench amplifiers. It is not uncommon to find features such as dynamic measurements, multiple factors, unilateral tolerances, different output formats, and micro-inch resolutions, in higher end digital indicators. And while they may be high-end for digital indicators, they are still about a quarter of the price of a bench amplifier and probe.

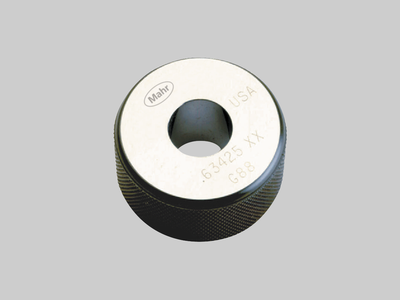

A common serious problem among users of dial indicators is the failure to notice when the pointer makes a full revolution or two. Parts that are grossly out of tolerance may appear to be within tolerances to an inattentive operator. In contrast, digital indicators never come "back to zero," eliminating this problem entirely. In fact, with the ability to display the actual part size, the idea of going back to "0" or reading deviations is fading away. Plus, all digital indicators can be made to signal out-of-tolerance dimensions, so little actual decision making is required by the user.

In spite of initial doubts, digital indicators have proven to be highly reliable in the shop floor environment. Most have only a single moving part, so they require less frequent cleaning than their mechanical cousins. And many now carry IP ratings that define the environment they can be used in, such as dust and water. With proper care, dial indicators can last virtually forever, and they never need batteries. However, there is also an increasing difficulty in finding people who can repair dial indicators.

Back in the '80s, the marketplace soundly rejected digital speedometers in cars. But today, as more and more people have been brought up in a digital world, there is a resurgence of digital speedometers, tachometers and other indicators. The same is true for digital indicators, and with operators growing used to them, they are taking on more and more applications.

Many of the latest digital indicators are becoming so powerful that they are taking on the performance and features of bench amplifiers. It is not uncommon to find features such as dynamic measurements, multiple factors, unilateral tolerances, different output formats, and micro-inch resolutions, in higher end digital indicators. And while they may be high-end for digital indicators, they are still about a quarter of the price of a bench amplifier and probe.