As with any dimensional check, there are as many different gaging approaches, as there are thicknesses, and the best solution depends on the requirements specified.

There are typically three or four different gage types commonly used for measuring thickness, ranging from the simplest to those that can measure to a millionth of an inch. Each one can successfully meet the requirement of the work while simplifying and speeding up the inspection process.

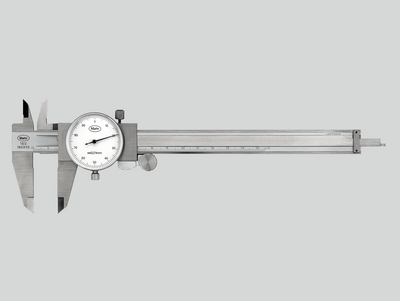

The two most common portable hand tools have been around for a hundred or more years: the dial indicator-based hand thickness gage and the handheld micrometer. A simple handheld indicator thickness gage is used for fast, general-purpose thickness checks. Typical applications include in-process verification checks of items being manufactured such as films, sheet metal or even small parts like washers as they fly off the manufacturing process. This type of gage “calipers” the film between its flat reference and sensitive anvils, providing a continuous and direct reading of part size compared to the reference anvil. Large retraction is provided with a lifting lever so that the gage is easily positioned on the part and provides wide use application.

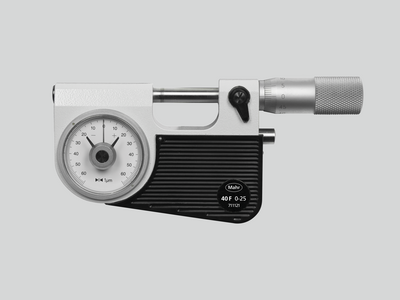

Micrometers can provide a similar form of thickness check, though there are some differences. Micrometers have flat contacts but the retraction and gaging is done by rotating the thimble. Thus retraction and gaging is longer and going to various sizes can take some time. There is also the issue of the rotating sensitive spindle. As the sensitive contact is rotated down onto the part – a film, for example – the rotating anvil can grab and twist the material. However, there are new micrometer designs today that will prevent this twisting and increase the speed of retraction and measuring. These new micrometers include a sliding measuring spindle and quicker threading to the thimble. This provides retraction speed five times faster than most micrometers. Though not as fast as an indicating thickness gage with its lifting lever, this type of thickness gage can provide better performance.

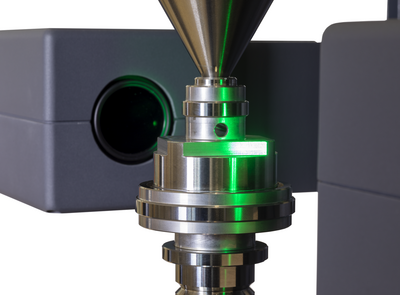

While some films are pretty durable, there are parts and materials where touching the part might be prohibitive. For example, silicon wafers and precision components may require non-contact measuring. Due to the delicacy of the parts, two opposed air jets can be used to provide this non-contact measurement. Because of the differential characteristics of measuring thickness without regard to position, this air gaging solution offers the protection and the performances needed for this thickness requirement.

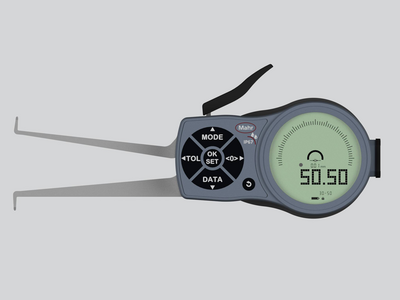

Compressibility is another consideration when measuring thickness. Imagine a number of sister plants making the same compressible film, all using different gages with separate gaging forces and contact shapes. It is unlikely there would be any correlation between this diverse gaging operation. However, the industry has established a set of standards for thickness gages that define gaging force and contact/anvil shapes and sizes. By having all the various plants use the same standard for their gages, all parts are being inspected the same way and the chances of correlation between plants increases.

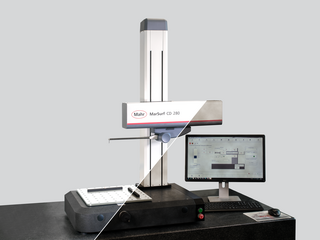

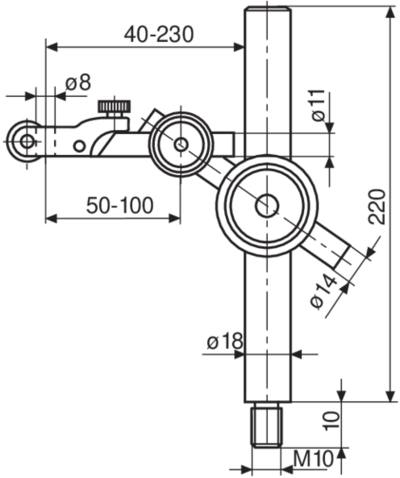

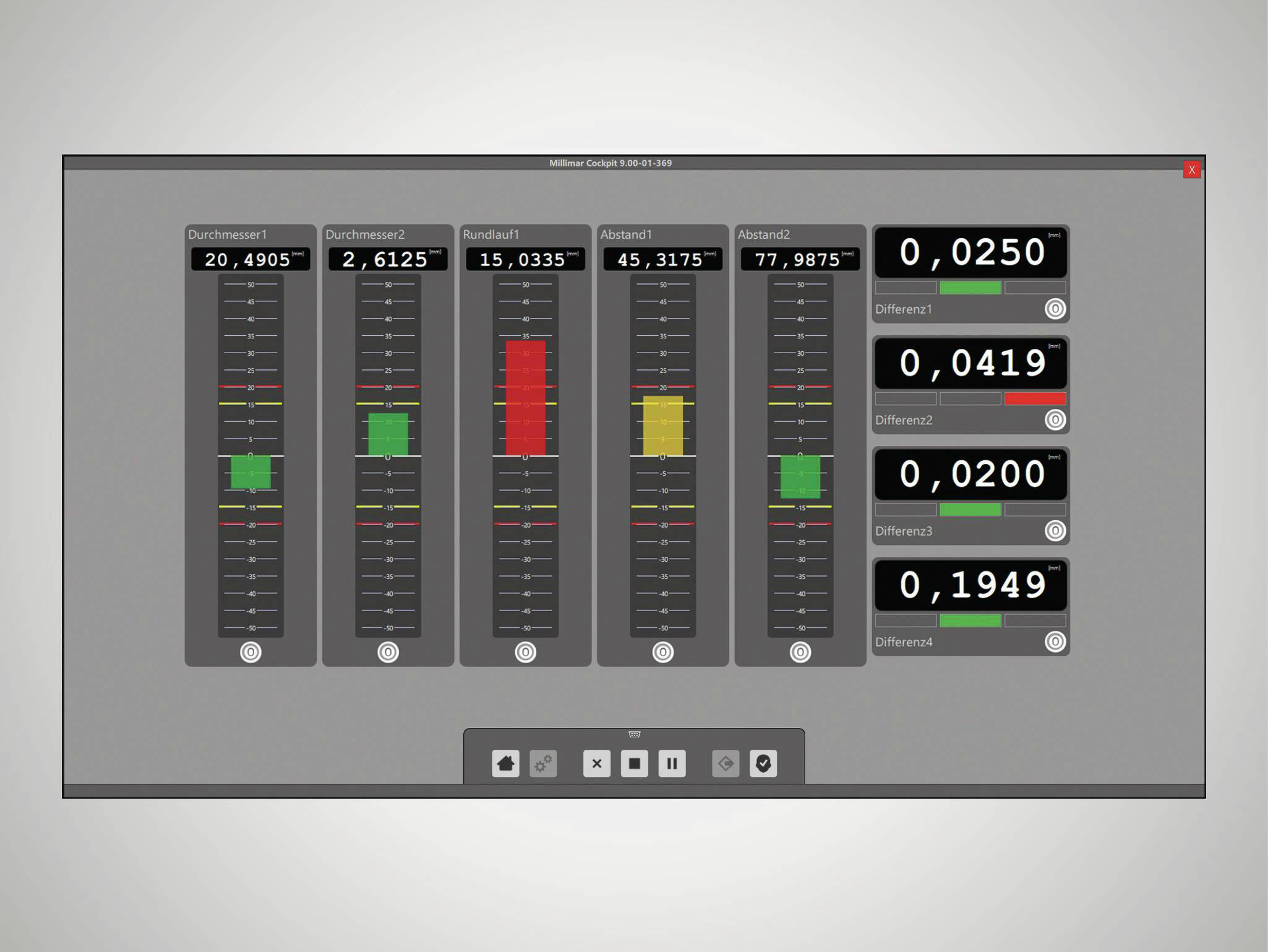

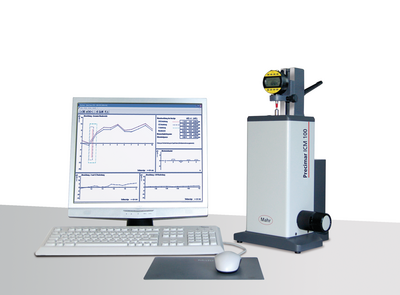

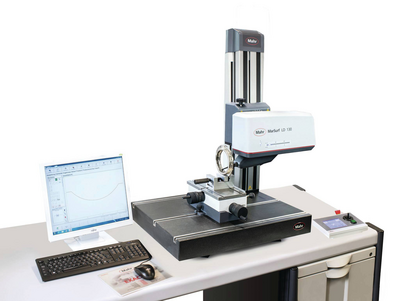

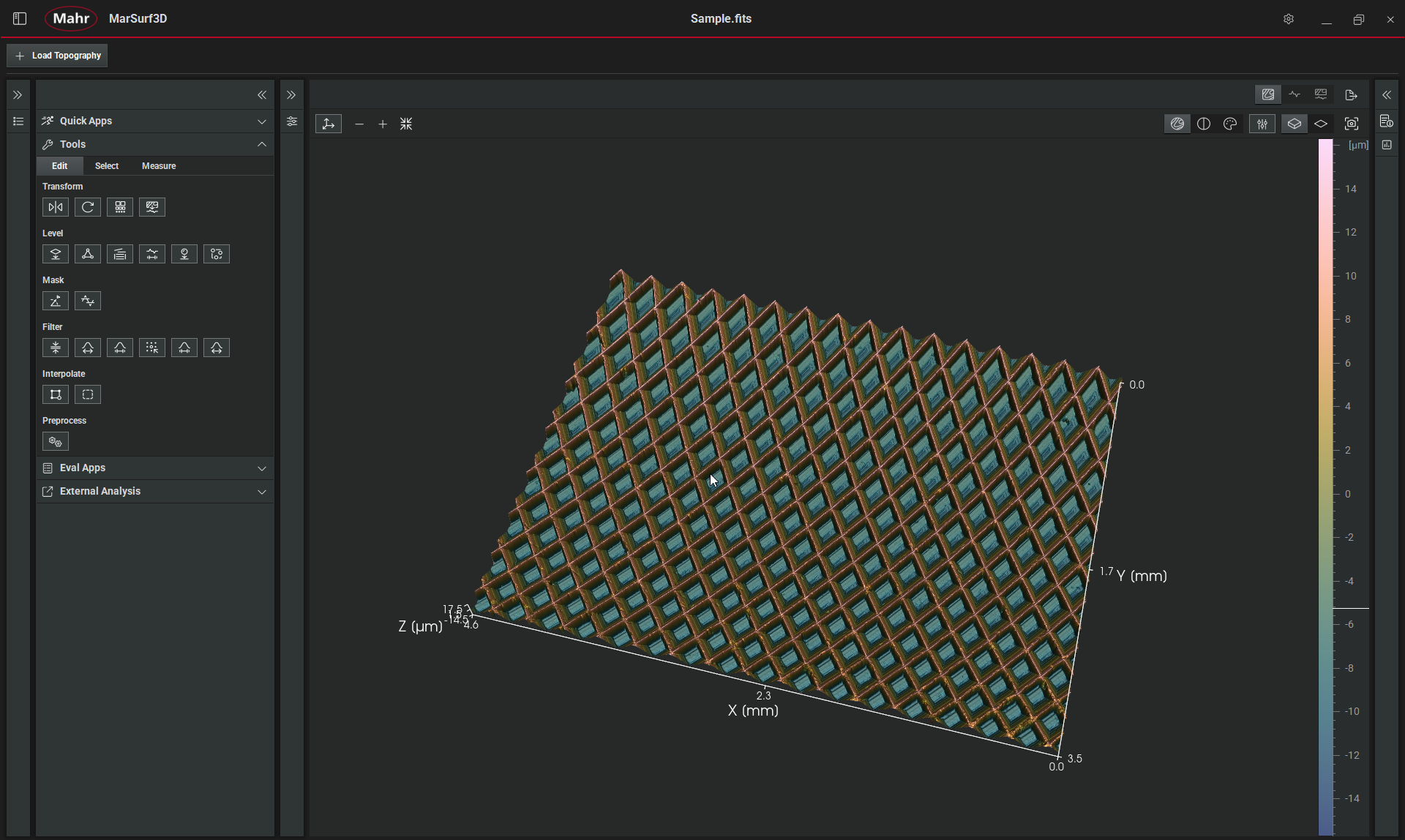

When considering thickness, one can imagine that gage blocks are also in fact thickness standards. As standards, the blocks must be measured in very precise thickness gages, following research and standards to find the proper and most exact ways to verify them. Being millionth class measuring instruments, these thickness gages must take into account, and squeeze out, any potential error. Therefore, the thickness gages have to be bench mounted, robust, used in environments consistent with millionth measurements, use differential gaging for point-to-point measurement, and factor in contact radius and gaging pressure as part of the process.

While thickness gages can range from portable pocket carried tools to precision lab systems, they are still used for one of the most common checks required today. It all comes down to matching the measuring tool to the measurement requirements—something that needs to be considered in any measurement task.