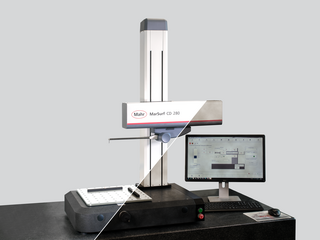

But certainty becomes elusive at the micro-inch level. State-of-the-art machining practice is only just capable of producing gage standards and gage blocks to the required degrees of accuracy. However, their dimensions, as well as those of the workpieces, change readily with changes in temperature, the accumulation of infinitesimal amounts of dust, and minute variations in gaging practice.

Uncertainty can't be eliminated, but manufacturers can successfully perform millionth measurements by relying upon relevant industry standards, which define how much uncertainty is permissible, and where. Particularly under ISO 9000, manufacturers must be able to document their use of reliable standards as the basis of their QA/QC efforts. But in all cases, uncertainty must be minimized, and one of the critical places to look for it is in mastering.

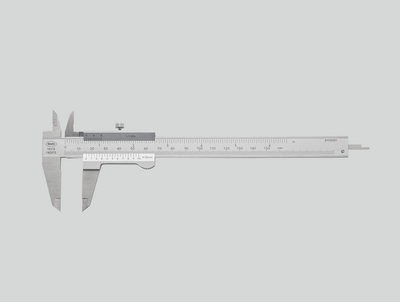

Gage blocks and masters have tolerances of dimension, surface roughness, and geometry: in other words, the master’s themselves have inherent uncertainty. When gage blocks are wrung together, stacking error is introduced, combining all these sources of error with the added uncertainty that two or more wrings with the same blocks may produce different results. Gage blocks and masters are also subject to wear, which becomes significant rapidly at microinch tolerances.

Under the old "ten to one" rule, if you're measuring parts to 30 millionths, you want gage repeatability of 3 millionths, and a master that's good to 0.3 millionths. No one makes gage blocks to that level of accuracy, so we have to compromise and accept rules of five to one, or even less. That may be the best we can do.

Gage blocks are a "primary" standard: that is, they are documented and traceable back to an official, absolute standard -- in the US, to the National Institute of Standards and Technology (NIST, formerly the National Bureau of Standards). Documentation makes it possible to determine the level of accuracy in each gage block. Master rings and discs, in contrast, are generally considered to be secondary standards, because their size is established by reference to gage blocks. Traceability is thus one step further removed, which implies a greater level of uncertainty.

To document and minimize the level of uncertainty, gage blocks should ideally be sent to NIST for recertification. This way, you'll be mastering your gage at a single remove from the absolute standard: you can't get any closer than that. However, this may be impractical for a number of reasons, and commercial calibration houses may be able to provide faster service.

If you use a commercial service, it is important to choose one that sends its own primary blocks to NIST for calibration, to avoid adding unnecessary levels of uncertainty. Consider the following scenario:

You send your gage blocks to XYZ Accuracy Inc. But XYZ has its own blocks certified by ABC House o' Blocks. ABC sends its primary blocks to NIST for certification. Your blocks end up certified at three removes from NIST, with contributions of the following sources of uncertainty.

NIST uncertainty: 0.7μ"

ABC uncertainty: 1.5μ"

XYZ uncertainty: 1.5μ"

Total = 3.7μ"

While uncertainty isn't necessarily cumulative, it's easy to see how levels of uncertainty that may be insignificant for tolerances of 0.001" or 0.0001" can become critical when you're trying to measure to 10 μ".

All this concern with mastering, calibration, and external standards is not an intellectual exercise of interest only to a chosen few: Any manufacturer hoping to meet microinch tolerances, obtain ISO 9000 certification, or satisfy many other industry standards, may be required to reference its measurement methods to officially recognized physical standards. Adequate traceability is an important issue, but one must be equally concerned with how many steps intervene between your own gage blocks and the official physical standard.