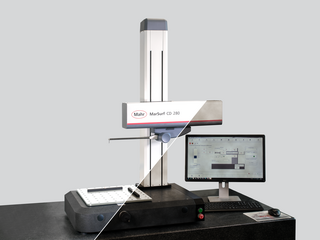

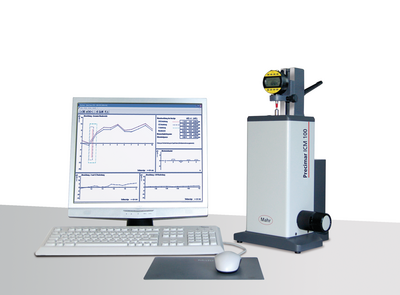

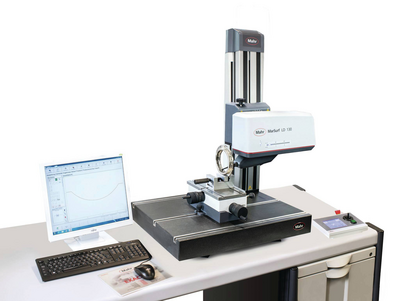

In fact, many digital height gages, can be thought of as single axis CMM’s or even a 2-axis version when using the built in functions to measure straightness or squareness.

As with a CMM, today’s Electronic Height Gage is computer based, touch screen operated systems that allow for automated measuring routines, error correction, multiple probe offsets and ability to easily create and run serial part programs.

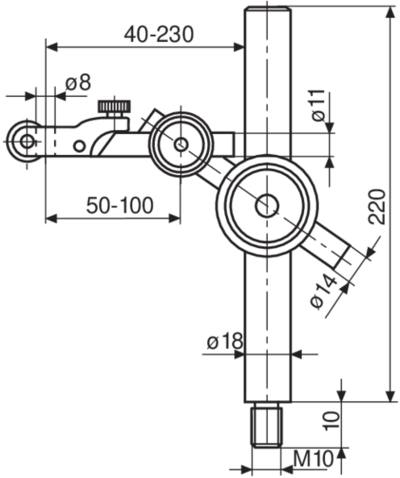

The typical size for height gages ranges between 350 mm to 1000 mm, but they are available in sizes up to 1800 mm. And with extensions even more capacity is possible. Height gages by themselves cannot make a measurement without a reference. With a height gage the reference is the surface plate, the foundation of all precision.

Once you have the height gage set in place, there are two critical references that need to be established. The first is the zero-reference for the measuring system. With automated height gages, this is done automatically whenever the gage is turned on; the gage will automatically move down to touch the surface to set its reference point.

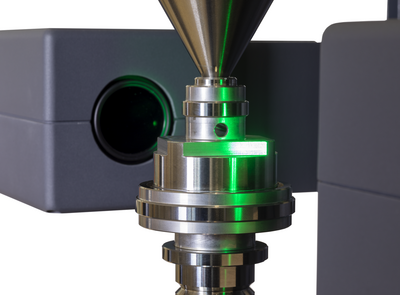

The other important reference is the correction for probe ball diameter. If a height gage is to be used only for length measurements taken with the probe moving down, then probe diameter is not important. The contact point of the probe will be the same as in zeroing. But, if grooves, diameters, or hole locations are being measured, or if any measurements are taken with the probe moving upwards, then the probe ball diameter must be known and considered.

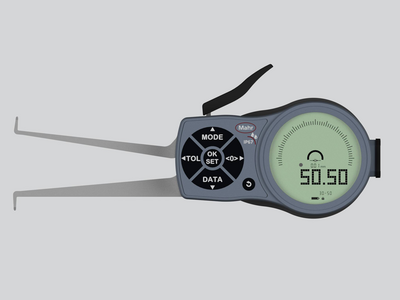

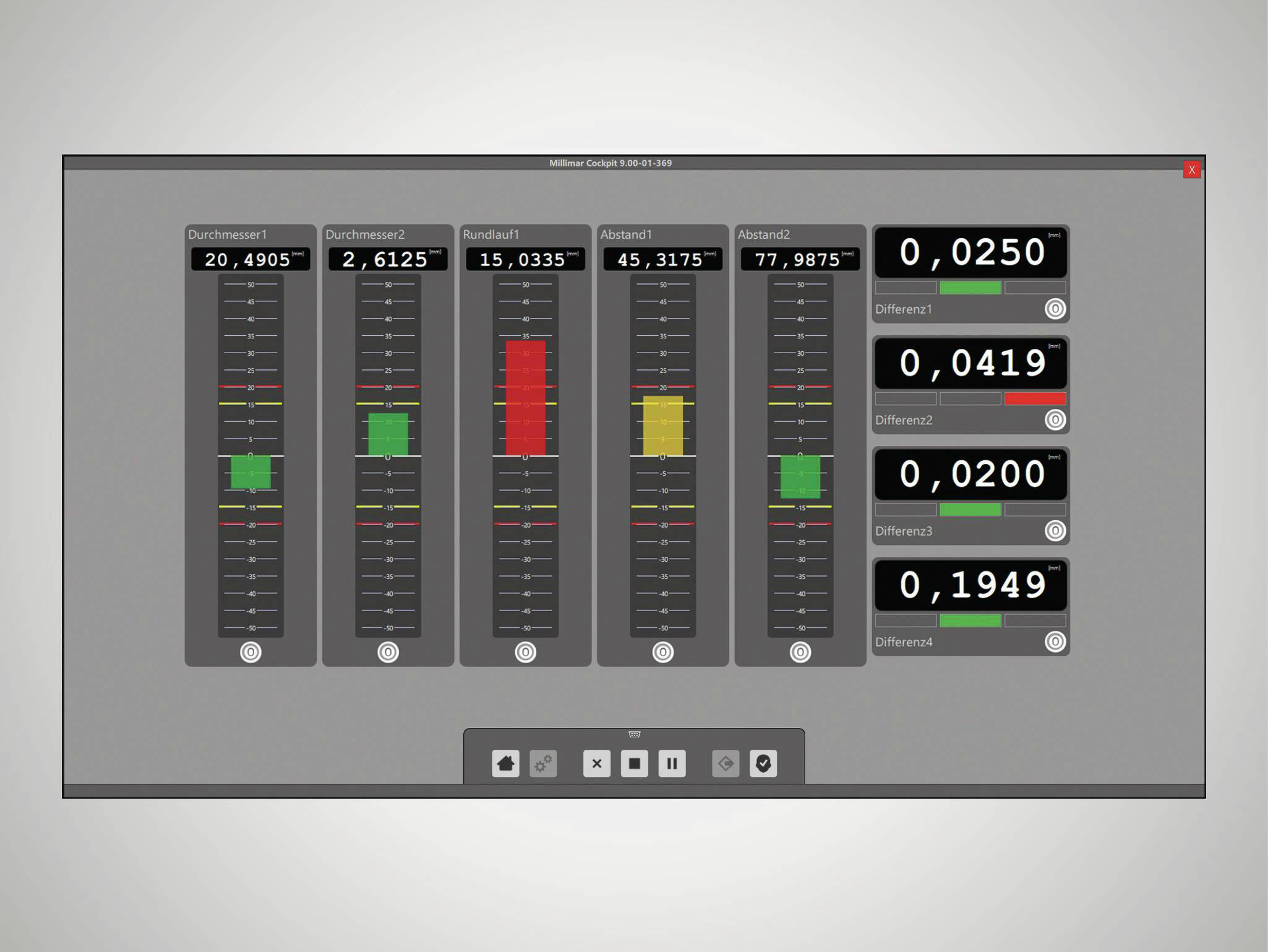

With the new motorized digital versions, measurement is an easy keystroke of an icon on a large touchscreen. When ready to make a measurement, say a height in reference to the zero point, slide the measuring carriage up over the part and press the height measurement icon, approaching from the top. The motorized drive will bring the contact to the surface and the measurement is completed and displayed. However, with the modern height gage this only begins the measuring capabilities. There are dedicated icons for most common measuring functions such as up/down lengths from the reference, outside/inside diameters, center distance, flatness and even taper measurements. If the height gage has 2D functions, then straightness and perpendicularity is the touch of an icon away.

As measurements are made, they are stored internally, and even more relationships between the stored data such as center distance and other relationships can be made without having to measure the part. The measuring process performed will also act as a basis for a part-time program. Since every measurement and routine are stored on the gage – this past measurement history can use used as a new part program. Thus, when the part comes along again or there are a series of similar parts to be measured, this routine becomes the part program for repeating the measuring process.

Besides using the measurement sequence as the basis for the creation of the part program the measurement results can be stored or saved in several different ways. The raw results can be saved as a file or stored to a USB stick, stored in a preformatted and customized PDF file or transferred to the network or cloud via cable or wirelessly for long time storage and analysis.

Today’s Height gages are feature packed and high-performance measuring systems. They can be thought of as single axis CMM’s. Considering that they implement canned measuring modes, can store part programs, could use different probes with various contact configurations and diameters and the ability to store/print gaging results they really do have all the same CMM capabilities for a single axis. When used on a good surface reference electronic height gages can offer substantial benefits in terms of time and productivity savings and high-quality measurements on the shop floor or as part of a receiving inspection area at a price that offers high value for the results provided.