Wysokiej jakości technika pomiarowa do kontroli jakości w hali pomiarowej, produkcji, przy dostawach towarów i rozwoju

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

współrzędnych walcowych Technika pomiaru kształtu i położenia Technika pomiaru wałów Optyczna technika pomiarowa Portal z urządzeniami używanymi

Innowacyjna ręczna technika pomiarowa Mahr: Suwmiarki, mikrometry i czujniki zegarowe, analogowe i cyfrowe, ze zintegrowanym układem do transmisji radiowej. Komparatory i wzorce odniesienia Mahr są niezbędne do precyzyjnej metrologii produkcyjnej.

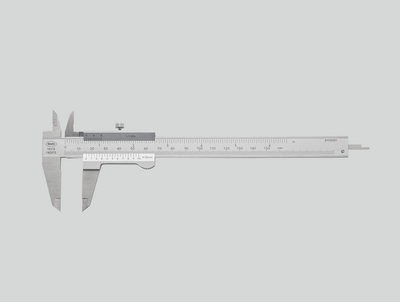

Od analogowych po cyfrowe: cała gama suwmiarek. Łatwa obsługa, łączność bezprzewodowa, a także wysoka dokładność. Idealne do zapewnienia efektywnej pracy w warunkach produkcyjnych.

Nasze cyfrowe suwmiarki odznaczają się cyfrowym wyświetlaczem, gwarantującym pewny odczyt, nowoczesnym designem i precyzją, do jakiej Mahr od dawna przyzwyczaił swoich klientów. Asortyment obejmuje przyrządy pomiarowe do wszystkich zastosowań. Liczne interfejsy do transmisji danych i stopień ochrony do IP 67 odpowiadają wszelkim wymaganiom.

Odczyt bez odbłysków, utwardzana stal, podwyższone prowadnice w celu ochrony podziałki i najwyższa dokładność. Cechy wysokiej jakości suwmiarki Mahr z klasycznym noniuszem.

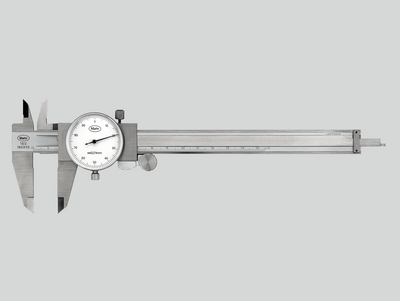

Duża, czytelna tarcza i wstrząsoodporny mechanizm pomiarowy zapewniający stały poziom precyzji. Mechaniczny klasyk do szybkich i bezpiecznych odczytów.

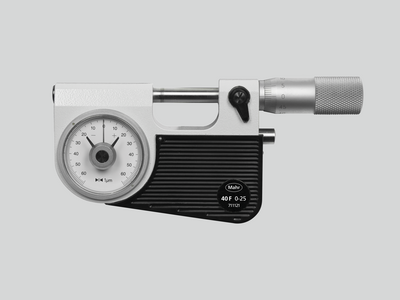

Najwyższa precyzja w różnych wersjach. Mikrometry Mahr są dostępne w klasycznych wersjach mechanicznych, cyfrowych i bezprzewodowych.

Nasze cyfrowe mikrometry kabłąkowe odznaczają się cyfrowym wyświetlaczem, gwarantującym nieomylny odczyt, nowoczesnym designem i precyzją, do jakiej Mahr zdążył już dawno przyzwyczaić swoich klientów. Asortyment obejmuje przyrządy pomiarowe do wszystkich zastosowań. Liczne interfejsy do transmisji danych i wysoki stopień ochrony do IP 65 odpowiadają wszelkim wymaganiom.

Odczyt bez odbłysków, płytki termoizolacyjne i precyzyjnie szlifowane wrzeciono dla najwyższej dokładności. Cechy jakościowego mikrometru Mahr.

Nadają się szczególnie do pewnego i szybkiego kontrolowania części produkowanych seryjnie (wały, sworznie, trzpienie). Odczyt zgodności wymiarowej na mikrokatorze od pierwszego rzutu okiem.

Do pomiaru dużych średnic i kontroli odległości do 2500 mm

Do wyboru ze skalą lub wyświetlaczem cyfrowym lub jako przyrząd do szybkiego pomiaru z uchwytem pistoletowym. 3-punktowe średnicówki Mahr zapewniają zawsze wiarygodne wyniki pomiarów dzięki automatycznemu centrowaniu.

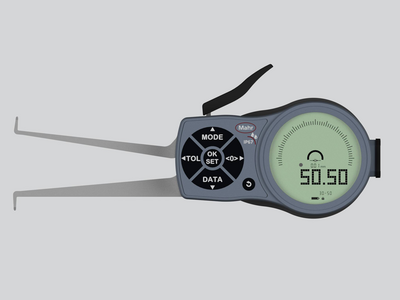

Od analogowych po cyfrowe: cała gama czujników zegarowych, mikrokatorów i czujników dźwigniowych. Łatwa obsługa, opcjonalnie bezprzewodowa, a także wysoka dokładność. Idealne do zapewnienia efektywnej pracy w warunkach produkcyjnych.

Wyraźny wyświetlacz cyfrowy, solidna konstrukcja i wysoka dokładność Mahr to cechy charakterystyczne naszych cyfrowych czujników zegarowych. Asortyment obejmuje przyrządy pomiarowe do wszystkich zastosowań. Liczne interfejsy do transmisji danych i wysoki stopień ochrony do IP 54 odpowiadają wszelkim wymaganiom.

Wysoka czułość i dokładność dzięki: wytrzymałemu łożyskowaniu osi mechanizmu pomiarowego, precyzyjnym kołom zębatym i zębnikom, precyzyjnie łożyskowanym trzpieniom pomiarowym.

W porównaniu z analogowymi czujnikami zegarowymi, mikrokatory Millimess mają jeszcze bardziej precyzyjne elementy, zapewniają większą dokładność pomiaru i znacznie mniejszy błąd histerezy Te zalety uwidaczniają się zwłaszcza w kontroli bicia poprzecznego, pomiarach prostoliniowości i płaskości oraz w pomiarach porównawczych.

Niezwykle precyzyjne mikrokatory Millimess oferują rozdzielczości do 0,2 μm. Praktyczne funkcje obsługi, np. monitorowanie tolerancji lub zapisywanie wartości skrajnych w pomiarach dynamicznych, połączenie wskaźnika cyfrowego i skali oraz prosty transfer danych sprawiają, że jest to niezastąpiony precyzyjny przyrząd pomiarowy.

Niezwykle czuły, zoptymalizowany komputerowo mechanizm pomiarowy zapewnia maksymalną wiarygodność wyników i precyzję. Z myślą o zastosowaniu w trudnych warunkach warsztatowych czujniki zostały wyposażone w odporną na zadrapania i pęknięcia szybkę z hartowanego szkła mineralnego, jak również uszczelkę chroniącą przed wnikaniem wody.

Niezwykle czuły, zoptymalizowany komputerowo mechanizm pomiarowy zapewnia maksymalną wiarygodność wyników i precyzję. Z myślą o zastosowaniu w trudnych warunkach warsztatowych obrotowy wyświetlacz jest doskonale zabezpieczony, jak również wyposażony w uszczelkę chroniącą przed wnikaniem wody.

Głowice pomiarowe 3D firmy Mahr do maszyn CNC, centrów obróbczych i obrabiarek elektroerozyjnych skracają czas ustawiania i przestojów. Idealne do dokładnego pomiaru krawędzi odniesienia na elementach mierzonych i urządzeniach.

Czy to Integrated Wireless, zewnętrzny moduł radiowy, USB, Opto RS232, czy Digimatic: Bez względu na to, z jakiego standardu interfejsu korzystasz, MarConnect zawsze zapewnia optymalne połączenie.

Wiele ręcznych mierników Mahr ma wyjście danych z interfejsem MarConnect. Niezależnie od stosowanego standardu interfejsu (USB, Opto RS232 lub Digimatic) MarConnect zapewnia zawsze optymalne połączenie.

Bezprzewodowe produkty Mahr gwarantują dokładne wyniki pomiarów przy całkowitej swobodzie ruchu. Pomiary nowoczesne i łatwe – bez przeszkadzających i plączących się kabli

Statywy pomiarowe, stoły pomiarowe i przyrządy do pomiaru bicia poprzecznego MarStand gwarantują stabilność, zapewniając tym samym precyzyjne wyniki pomiarów. Niezbędna pomoc przy czujnikach zegarowych, mikrokatorach, czujnikach dźwigniowych i głowicach pomiarowych.

Statywy pomiarowe gwarantują stabilność, zapewniając tym samym precyzyjne wyniki pomiarów. Niezbędna pomoc przy czujnikach zegarowych, mikrokatorach, czujnikach dźwigniowych i głowicach pomiarowych.

Statywy pomiarowe MarStand są dostosowane do indywidualnych rozwiązań i dzięki stabilnej konstrukcji są podstawą do uzyskiwania precyzyjnych wyników pomiarów. Niezbędne dla czujników zegarowych, mikrokatorów, trzpieniowych urządzeń pomiarowych i czujników pomiarowych.

Połączenie precyzyjnie wypoziomowanego stołu pomiarowego, stabilnej kolumny pomiarowej i wytrzymałych elementów ramienia to cechy charakterystyczne stołów pomiarowych. Stoły pomiarowe MarStand dzięki swojej wyjątkowo stabilnej konstrukcji stanowią podstawę do uzyskania precyzyjnych wyników pomiarów.

Przyrządy do kontroli bicia poprzecznego stanowią najprostszy sposób wykrywania błędów położenia i kształtu na wałach w środowisku produkcyjnym. Dzięki różnorodności modeli wytrzymałe przyrządy do kontroli bicia poprzecznego MarStand stanowią podstawę dla najróżniejszych wymagań dotyczących elementów mierzonych i dokładnych wyników pomiarów.

Płyty pomiarowe wykonane z twardego granitu stanowią doskonałą podstawę dla wysokościomierzy dzięki ich wysokiej wytrzymałości i stabilności wymiarowej.

Wskazujące przyrządy pomiarowe jako komparatory są idealne do precyzyjnych pomiarów w produkcji. Ustawienie względem wzorca odniesienia zmniejsza margines odchyłki i minimalizuje wpływ wahań temperatury na wynik pomiaru.

Dokładne mikrokatorowe sprawdziany szczękowe są idealnymi przyrządami pomiarowymi do precyzyjnych pomiarów części cylindrycznych, takich jak wałki, sworznie i trzpienie, zwłaszcza do bezpiecznych i szybkich kontroli części seryjnych. Odczyt zgodności wymiarowej na mikrokatorze od pierwszego rzutu okiem.

Średnicówki idealnie nadają się do precyzyjnego pomiaru otworów pod względem średnicy, okrągłości i stożkowości.

Za sprawą naszych grubościomierzy oferujemy solidny i prosty asortyment produktów do bardzo szybkiego pomiaru folii, arkuszy i płyt wszelkiego rodzaju.

Jeśli ze względu na geometrię mierzonego elementu nie można zastosować zwykłych przyrządów pomiarowych, takich jak suwmiarki czy średnicówki mikrometryczne, idealnym rozwiązaniem są przyrządy z ramieniem pomiarowym!

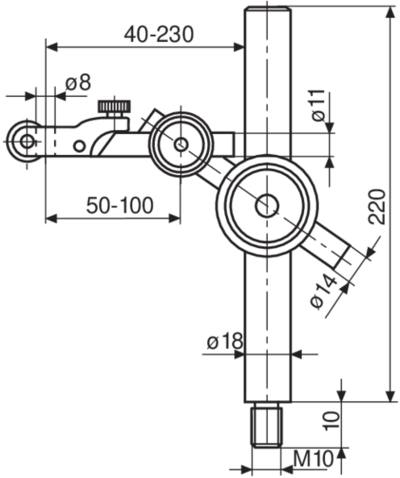

Za sprawą naszych mostków do pomiaru głębokości oferujemy solidny i prosty asortyment produktów do bardzo szybkiego pomiaru głębokości. Trzpień chwytowy 8 mm w zależności od zadania pomiarowego umożliwia stosowanie czujników zegarowych, mikrokatorów i głowic pomiarowych.

Mierniki uniwersalne jako komparatory idealnie nadają się do precyzyjnych pomiarów w produkcji, ponieważ pomiar porównawczy względem wzorca odniesienia minimalizuje wpływ wahań temperatury na wynik pomiaru.

Uzębienia, gwinty, stożki czy podcięcia: Urządzenia uniwersalne Multimar oferują optymalne rozwiązanie do prawie wszystkich pomiarów wewnętrznych i zewnętrznych, które nie mogą zostać wykonane za pomocą standardowych przyrządów pomiarowych. Do dyspozycji są różne urządzenia podstawowe i bogaty asortyment akcesoriów.

Dokładna regulacja przyrządów do pomiarów wewnętrznych i zewnętrznych. Urządzenia nastawcze 844 S to optymalne wyposażenie dla każdego zadania pomiarowego – również wielkowymiarowego.

Kołnierze centrujące, wąskie odsadzenia czy podcięcia: Uniwersalne przyrządy pomiarowe Multimar 36B oferują optymalne rozwiązanie do prawie wszystkich pomiarów wewnętrznych i zewnętrznych. Do dyspozycji są różne urządzenia podstawowe i bogaty asortyment akcesoriów.

Postaw na wzorce i sprawdziany Mahr – stanowią podstawę precyzyjnych wyników pomiarów.

Postaw na wzorce nastawcze Mahr – stanowią podstawę precyzyjnych wyników pomiarów.

Płytki wzorcowe Mahr zapewniają wysokiej jakości wzorce odniesienia i użytkowe. Do wyboru są 4 klasy tolerancji i 2 materiały odpowiednie do warsztatu, produkcji lub na potrzeby zapewnienia jakości.

Wałeczki kontrolne Mahr są dostępne w 3 klasach tolerancji i różnych wersjach. Do wyboru są elementy odpowiednie do konkretnego warsztatu, produkcji lub na potrzeby zapewnienia jakości.

Wymagania dotyczące elektrycznych przyrządów do pomiaru długości są prawie tak zróżnicowane jak ich zastosowania. Oczekuje się od nich maksymalnej niezawodności i precyzji oraz bardzo prostej obsługi.

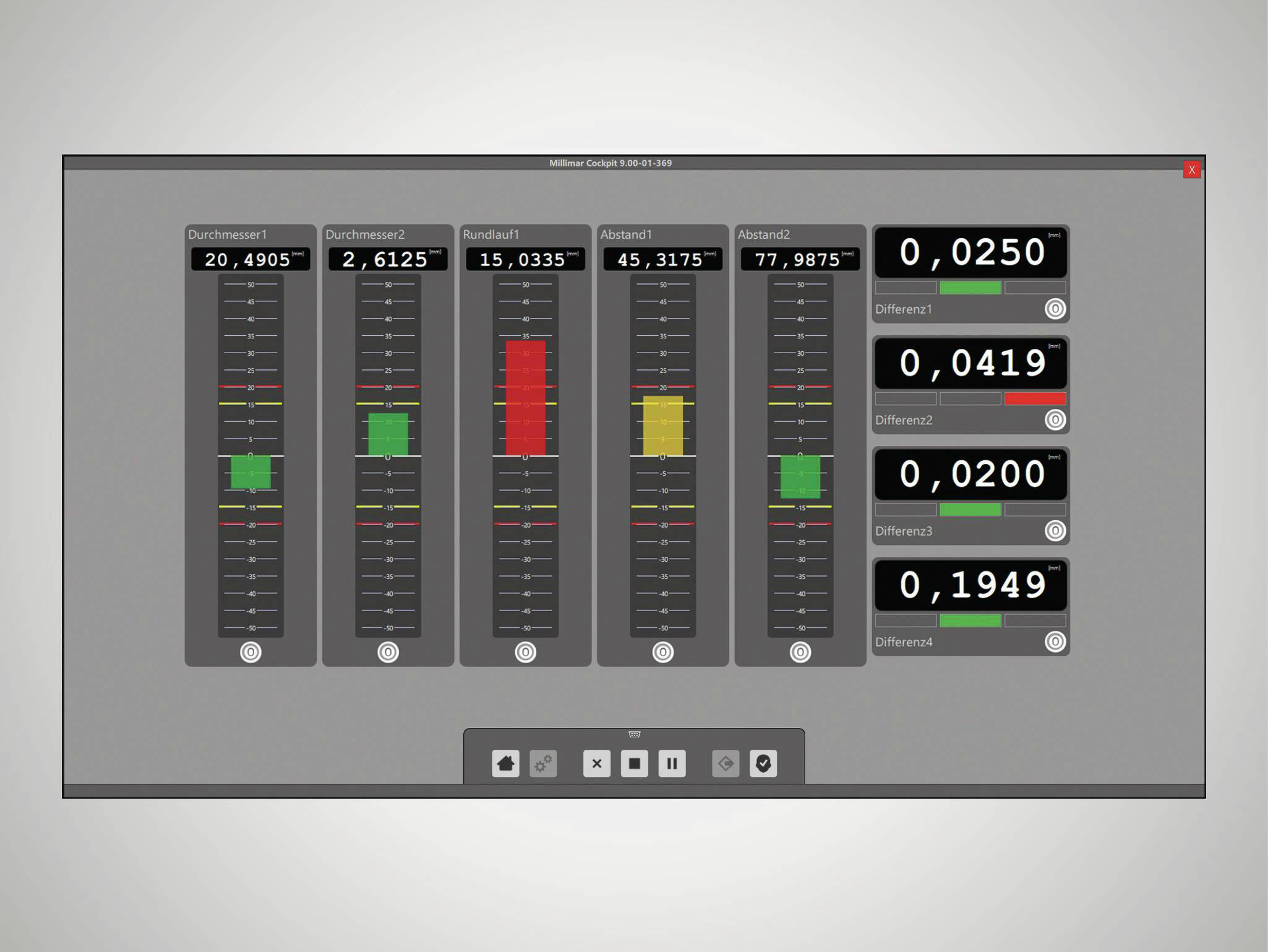

Wymagania dotyczące elektrycznych przyrządów do pomiaru długości są prawie tak zróżnicowane jak ich zastosowania. Oczekuje się od nich maksymalnej niezawodności i precyzji oraz bardzo prostej obsługi. Kompaktowe i kolumnowe urządzenia pomiarowe Millimar spełniają te wymogi.

Przyrządy do pomiaru długości Millimar są kompaktowe, wytrzymałe i łatwe w użyciu. Są to uniwersalne urządzenia analizujące i wskazujące do zadań pomiarowych o niewielkiej złożoności w obszarze produkcyjnym i w pomieszczeniu pomiarowym.

Dzięki różnorodnym możliwościom łączenia modułów i oprogramowania użytkownik może z niespotykaną do tej pory swobodą kształtować swoje środowisko pracy i narzędzia.

Inteligentne i uniwersalne oprogramowanie przeznaczone do kompleksowych pomiarów w środowisku produkcyjnym

Czujniki pomiarowe Millimar są najbardziej istotnymi komponentami łańcucha pomiarowego. Ich właściwości decydują o jakości całego pomiaru. W zależności od zastosowania dostępne są różne czujniki pomiarowe. Na przykład indukcyjne głowice pomiarowe Millimar: cechują się solidną konstrukcją, uniwersalnością co do zastosowania i atrakcyjną ceną.

Niezależnie od tego, czy chodzi o pomiar grubości, bicia poprzecznego, czy koncentryczności: dzięki głowicom indukcyjnym można rejestrować zmierzone wartości i odchylenia niezależnie od kształtu, podparcia czy odchyłek bicia poprzecznego. Ich wielką zaletą jest duży zakres liniowości i względna niewrażliwość na zakłócenia. Głowice są stosowane głównie do pomiarów porównawczych w produkcji, ale konkretne zadania czujnika mogą być różne.

Pneumatyczne przyrządy do pomiaru długości charakteryzują się wysoką dokładnością długotrwałą stabilnością. Pomiar bezkontaktowy za pomocą dysz pomiarowych nie powoduje żadnych uszkodzeń elementów mierzonych. Bezproblemowy i niezawodny pomiar nieoczyszczonych, naoliwionych, nasmarowanych lub docieranych elementów jest możliwy, ponieważ punkty pomiarowe są czyszczone powietrzem pomiarowym.

Przyrządy do pomiaru długości Millimar są kompaktowe, wytrzymałe i łatwe w użyciu. Są to uniwersalne urządzenia wskazujące i analizujące do zadań pomiarowych o niewielkiej złożoności w obszarze produkcyjnym.

Wyniki pomiarów są wyświetlane za pośrednictwem 101 trójkolorowych diod elektroluminescencyjnych, które są łatwe do odczytania nawet z dużej odległości. W przypadku przekroczenia programowalnych granic ostrzeżeń i tolerancji segmenty zmieniają kolor z zielonego na żółty lub czerwony.

Mierniki pneumatyczne Millimar szybko i dokładnie wykrywają odchylenia wymiarowe. Od lat sprawdzają się one jako wysokiej jakości pneumatyczne przyrządy do pomiaru długości w produkcji przemysłowej i w pomieszczeniach pomiarowych.

Gdy pomiar i analiza mają być przeprowadzane mobilnie.

Bezkontaktowy pomiar za pomocą pneumatycznych pierścieni pomiarowych, brak uszkodzeń elementów mierzonych.

Dostosuj stanowisko pomiarowe do danego zadania pomiarowego za pomocą akcesoriów do techniki pomiarów pneumatycznych.

Postaw na wzorce nastawcze Mahr – stanowią podstawę precyzyjnych wyników pomiarów

Ustawianie pneumatycznych przyrządów pomiarowych (dyszowe pierścienie pomiarowe). Starannie hartowane, starzone, szlifowane i polerowane.

Ustawianie pneumatycznych przyrządów pomiarowych (dyszowe trzpienie pomiarowe). Starannie hartowane, starzone, szlifowane i polerowane.

Chcesz mierzyć wysoko swoimi pomiarami? Do tego celu przyda się Digimar!

Do trasowania i zaznaczania elementów w warsztacie. Łatwy pomiar wysokości i odległości.

Praktyczne tryby i opcje pomiaru: Digimar 814 C ułatwia wykonywanie typowych zadań pomiarowych

Obsługa dotykowa, ergonomia i szeroki zakres możliwości analizy: Taki właśnie jest wysokościomierz Digimar 816 CLT.

Obsługa dotykowa, ergonomia i szeroki zakres możliwości analizy: Taki właśnie jest wysokościomierz Digimar 817 CLT.

Obsługa dotykowa, ergonomia i szeroki zakres możliwości analizy: Taki właśnie jest wysokościomierz Digimar 817 CLT.

Precyzyjna technika pomiaru długości to technika pomiarów wielkości geometrycznych o najwyższej precyzji – zarówno do pomiarów bezwzględnych, jak i względnych.

Uniwersalne, łatwe w użyciu urządzenia do pomiaru i ustawiania długości w produkcji

Uniwersalne, łatwe w użyciu urządzenia do pomiaru i ustawiania długości w produkcji

Dzięki szerokiej palecie produktów – od prostego stanowiska do kontroli płytek wzorcowych, w pełni automatycznego stanowiska do kontroli czujników zegarowych i urządzeń ULM po ultradokładne i półautomatyczne uniwersalne maszyny pomiarowe CiM – Mahr oferuje praktyczne rozwiązania do zastosowania w produkcji, pomieszczeniach pomiarowych i laboratoriach. Innymi słowy: Technika pomiaru o najwyższej precyzji i maksymalnie wydajnych procesach pomiarowych.

Czy są to klasyczne urządzenia ULM, czy urządzenia zmotoryzowane PLM i CiM. Uniwersalne maszyny do pomiaru długości Mahr umożliwiają wygodne, szybkie i wiarygodne pomiary z najmniejszą możliwą niepewnością.

Półautomatyczna i automatyczna kontrola czujników zegarowych, trzpieniowych przyrządów pomiarowych, mikrokatorów i głowic indukcyjnych – wydajna i precyzyjna.

Półautomatyczna i automatyczna kontrola czujników zegarowych, trzpieniowych przyrządów pomiarowych, mikrokatorów i głowic indukcyjnych – wydajna i precyzyjna.

Ręczna kontrola czujników zegarowych, szczelinomierzy i precyzyjnych wskaźników

Postaw na stanowiska do kontroli płytek wzorcowych Mahr – stanowią podstawę precyzyjnego testowania wzorców

Mikroskopy są wykorzystywane w prawie wszystkich gałęziach przemysłu do szybkiej kontroli odległości, promieni i kątów. W laboratorium lub na miejscu produkcji.

Do szybkiej analizy elementów geometrycznych

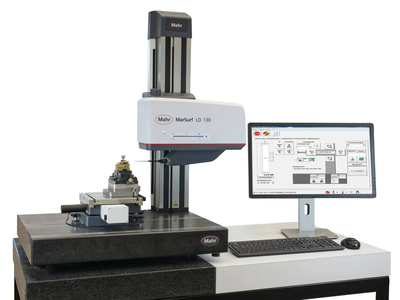

Technika pomiaru powierzchni dla przemysłu i badań naukowych

Technika pomiaru powierzchni dla przemysłu i badań naukowych

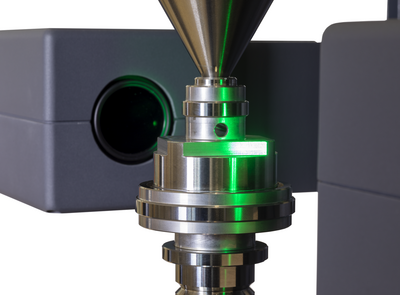

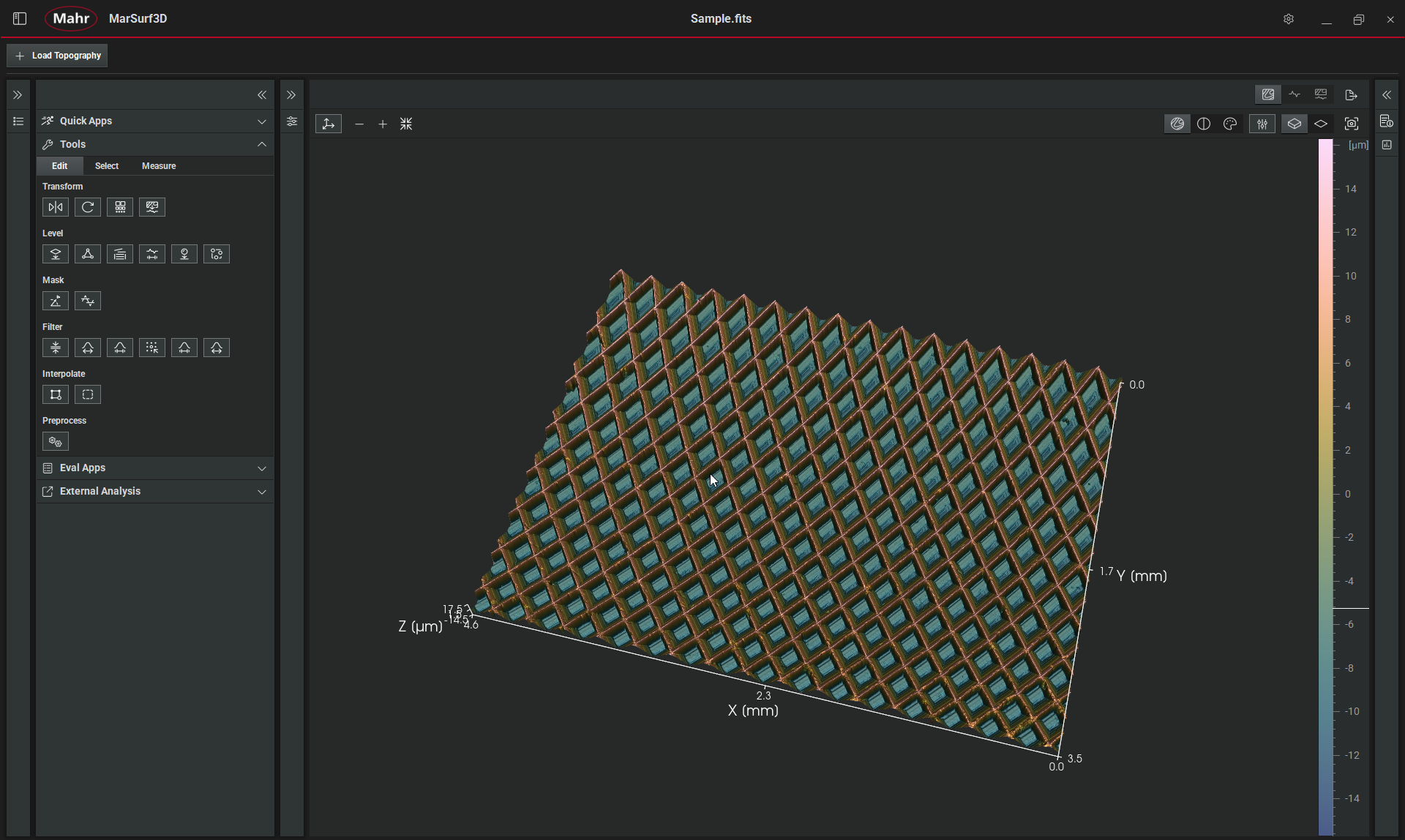

Strukturalne powierzchnie funkcjonalne o wąskich tolerancjach wymagają wysoce precyzyjnych systemów pomiarowych, które w krótkim czasie rejestrują topografię elementu mierzonego lub obiektu.

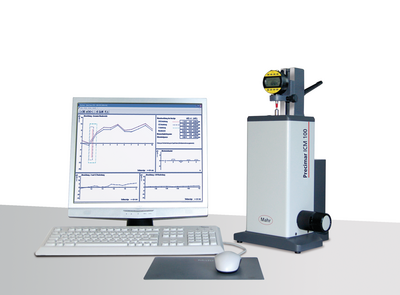

Technika pomiaru konturów jest wykorzystywana do określenia zgrubnego odchyłek kształtu.

Precyzyjny pomiar konturów za pomocą optycznych przyrządów pomiarowych

Połączenie pomiaru konturów i chropowatości: Profesjonalista do wielu zadań pomiarowych

Połączenie pomiaru konturów i chropowatości: Profesjonalista do wielu zadań pomiarowych

Pomiary konturów i chropowatości 2D/3D wg ISO 25178 / ISO 4287

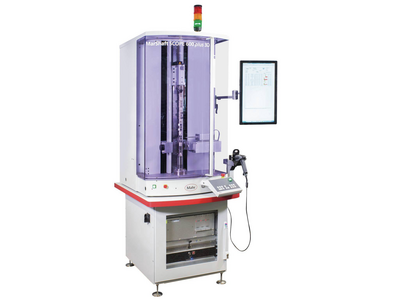

Technika pomiaru powierzchni 3D dla przemysłu i badań naukowych

Wykonuj pomiary w dowolnym miejscu dzięki przenośnym przyrządom pomiarowym!

Stanowiska pomiarowe do pomiarów optyki precyzyjnej

Gdy standard nie wystarcza: Indywidualne rozwiązania dopasowane do życzeń klienta

Strukturalne powierzchnie funkcjonalne o wąskich tolerancjach wymagają wysoce precyzyjnych systemów pomiarowych, które w krótkim czasie rejestrują topografię elementu mierzonego lub obiektu.

Uniwersalne i wydajne – w pomieszczeniu pomiarowym i laboratorium

Połączenie pomiaru konturów i chropowatości: Profesjonalista do wielu zadań pomiarowych

Stykowe stanowiska pomiarowe do pomiarów konturów i chropowatości

Pomiary konturów i chropowatości 2D/3D zgodnie z ISO 25178 / ISO 4287

Technika pomiaru powierzchni 3D dla przemysłu i badań naukowych

Wykonuj pomiary w dowolnym miejscu dzięki przenośnym przyrządom pomiarowym!

Przenośna technika pomiaru powierzchni 3D do

zastosowania w miejscu pracy

Dzięki przenośnym przyrządom pomiarowym można wykonywać pomiary zawsze tam, gdzie potrzebne są wyniki.

Stanowiska pomiarowe do pomiarów optyki o największej precyzji

Gdy standard nie wystarcza: Indywidualne rozwiązania dopasowane do życzeń klienta

współrzędnych walcowych

Większa wydajność w środowisku produkcyjnym dzięki wyjątkowym atutom naszego wyposażenia i dużej elastyczności w kwestii wymiarów mierzonych części.

Elastyczny pomiar elementów mierzonych mocowanych między kłami centrującymi

Bardzo szybka optyczna kamera matrycowa o dużej rozdzielczości do pomiaru dużej ilości parametrów na elementach obrotowo-symetrycznych.

Szybka optyczna kamera matrycowa w połączeniu z wysoce precyzyjnymi systemami pomiarowymi do pomiaru dużej liczby parametrów na elementach obrotowo-symetrycznych.

Elastyczne możliwości mocowania i wysoce precyzyjne pozycjonowanie za pomocą w pełni automatycznego stołu centrująco-wychylnego

Bardzo szybka optyczna kamera matrycowa o dużej rozdzielczości do pomiaru dużej ilości parametrów na elementach obrotowo-symetrycznych. Doposażenie w pełni automatycznego stołu centrująco-wychylnego do bardzo szybkiego, mechanicznego pozycjonowania i elastycznych możliwości mocowania.

Bardzo szybka optyczna kamera matrycowa o dużej rozdzielczości do pomiaru dużej ilości parametrów na elementach obrotowo-symetrycznych. Doposażenie w pełni automatycznego stołu centrująco-wychylnego do bardzo szybkiego, mechanicznego pozycjonowania, łatwego mocowania i np. pomiarów wewnętrznych.

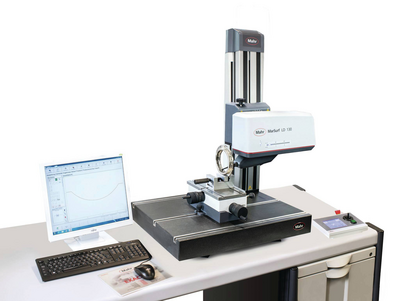

Systemy do pomiaru tolerancji kształtu i położenia, np. okrągłości, płaskości, prostoliniowości i współosiowości. Od rozwiązań ręcznych do w pełni zautomatyzowanych.

Łatwy, ekonomiczny i jednocześnie bardzo precyzyjny pomiar takich cech jak okrągłość, prostoliniowość i bicie. Nasze ręczne urządzenia do pomiaru kształtu nadają się zarówno do pomieszczeń pomiarowych, jak i do pomiaru w miejscu produkcji.

Dzięki naszym automatycznym systemom do pomiaru kształtów można obniżyć koszty procesu bez zwiększania kosztów kontroli dzięki stabilnym, innowacyjnym urządzeniom o wysokim stopniu automatyzacji, elastyczności i dokładności.

współrzędnych walcowych

Większa wydajność w środowisku produkcyjnym dzięki wyjątkowym atutom naszego wyposażenia i dużej elastyczności co do wielkości mierzonych części.

Elastyczny pomiar elementów mierzonych mocowanych między kłami centrującymi

Elastyczne możliwości mocowania i wysoce precyzyjne pozycjonowanie za pomocą w pełni automatycznego stołu centrująco-wychylnego

Optyczne i stykowe systemy do pomiaru wałów do zastosowań w w trudnych warunkach produkcyjnych. Kompletny pomiar wszystkich powszechnie stosowanych elementów obrotowo symetrycznych.

.Uniwersalne, w pełni automatyczne i wytrzymałe optyczne urządzenia do pomiaru wałów, przeznaczone do pracy w trudnych warunkach produkcyjnych.

Optyczno-stykowe przyrządy do pomiaru wałów do zastosowań w trudnych warunkach produkcyjnych. Kompletny pomiar wszystkich powszechnie stosowanych elementów obrotowo symetrycznych.

współrzędnych walcowych

Większa wydajność w środowisku produkcyjnym dzięki wyjątkowym atutom naszego wyposażenia i dużej elastyczności co do wielkości mierzonych części.

Elastyczny pomiar elementów mierzonych mocowanych między kłami centrującymi

Elastyczne możliwości mocowania i wysoce precyzyjne pozycjonowanie za pomocą w pełni automatycznego stołu centrująco-wychylnego

Szeroki zakres technologii i produktów do szybkiego i bezkontaktowego rozpoznawania powierzchni i geometrii.

Do szybkiej analizy elementów geometrycznych

Określanie chropowatości, konturu i wielu innych parametrów powierzchni.

Technika pomiaru powierzchni dla przemysłu i badań naukowych

Minimalne chropowatości z dokładnością do nanometra

Analiza optyczna topografii powierzchni i geometrii

Technika pomiaru powierzchni dla przemysłu i badań naukowych

Surface metrology for industry and research

Zregenerowane systemy o sprawdzonej jakości Mahr

MarTool calipers are characterized by essential technology and easy operation.

All theese in good professional quality, at the best price!

16 E -- Simple with essential features

16 ES -- High quality with essential features

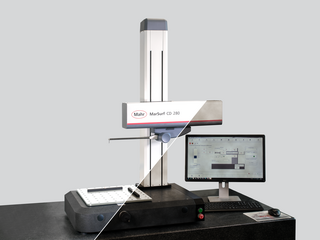

Engineered Solutions MarSurf Engineered Series 503

Nr art. 9900503_MES

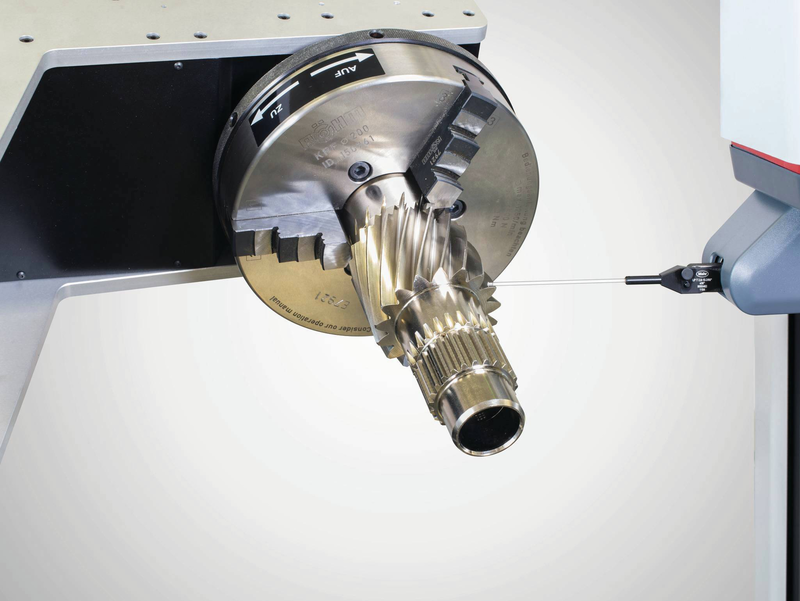

This measuring station can be used for partly automated roughness and contour measurements on tooth flanks or in tooth gaps. The outer teeth and helical teeth can be measured. The inner teeth can be measured with the offset probe. The limits are set by the max. offset of the probe arm and the helix angle of the teeth.

Flexible use

This measuring station can be used to measure different workpieces. The rotation axis has a jaw chuck so that workpieces on bores or outer geometries can be recorded.Rotationally symmetrical spline shafts with a diameter of up to 70 mm and a length of 500 mm can be clamped reliably.

The weight of the workpiece must not exceed 10 kg.

The user specifies the measuring procedure. The operators no longer need to be measuring technology specialists to complete complex measuring tasks – text and images in the operator guidance instruct the operator and reduce errors.

The complicated and manual setup of the measuring points is no longer necessary due to the sophisticated axis setup with three rotational axes.

The daily tasks of the operator are supported and simplified with photos and instructions.

Flexible use of the measuring station thanks to jaw chuck with release for shafts up to 500 mm long

Based on the entered gear parameters, several teeth on the circumference of the gear can be measured automatically.