Высококачественные измерительные решения для контроля качества на участках ОТК, на производстве, при входном контроле деталей и при опытно-конструкторских работах.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

As an internationally active company, Mahr holds its patents not only in Germany, but worldwide.

Инновационный ручной измерительный инструмент Mahr: Штангенинструмент, микрометрический инструмент и индикаторы часового типа #96 как с цифровым отсчетным устройством, так и со шкальной индикацией, со встроенным беспроводным интерфейсом Integrated Wireless. Приборы для относительных измерений и образцовые меры Mahr являются незаменимыми инструментами для производственной метрологии.

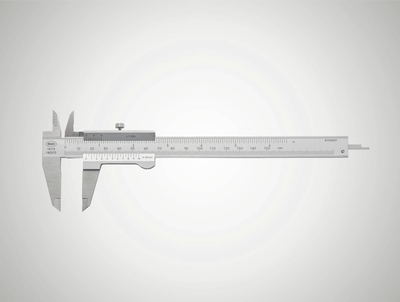

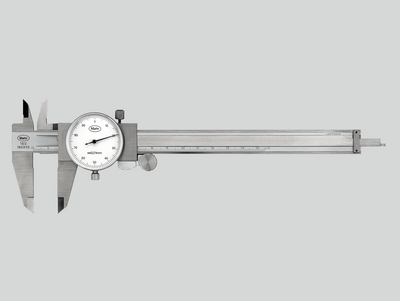

From analog to digital, the entire spectrum of calipers. Easy handling, wireless, and highly accurate. Perfect for efficient use in manufacturing.

Штангенциркули с цифровым отсчетным устройством отличает надежность и простота считывания цифровой индикации, современный дизайн и точность, присущая приборам Mahr. Ассортимент включает измерительные приборы для всех областей применения. Различные интерфейсы передачи данных и степень защиты до IP67 обеспечивают выполнение любых требований.

Отсутствие бликов, затрудняющих считывание показаний, закаленная сталь, приподнятые направляющие для защиты шкалы от износа и высочайшая точность. Возможности качественного штангенциркуля Mahr и классического нониусного штангенциркуля.

Large, high-contrast dial and shock-protected measuring tool for lasting precision. A tried and tested mechanical design for fast and safe reading.

Maximum precision in a variety of designs. Micrometers from Mahr are available in conventional mechanical and digital and wireless versions.

A clear digital display, modern design and the usual Mahr accuracy characterize our digital outside micrometers. The range includes measuring instruments for all applications. Various interfaces for data transmission and a high protection rating up to IP 65 leave no demands unfulfilled.

Максимальная точность благодаря отсутствию бликов, затрудняющих считывание показаний, теплоизоляционным накладкам и точно доведенному микрометрическому винту. Возможности качественного микрометра Mahr.

Особенно хорошо подходит для надежного и быстрого контроля серийных деталей (валов, болтов/шпилек, хвостовиков). Быстрое и точное считывание линейных размеров с помощью измерительной головки.

Suitable for measuring large diameters and testing distances up to 2,500 mm

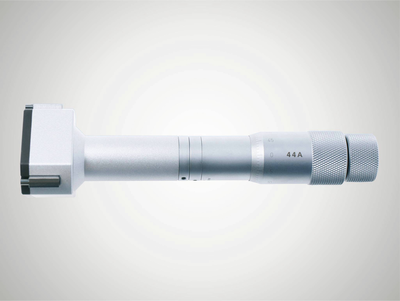

Available with scale or digital display or as a quick-measuring instrument with pistol-type grip. The Mahr 3-point inner measuring devices always provide reliable measuring results due to automatic self-centering.

Anti-glare reading and a precision-ground spindle for maximum accuracy. Features of a quality micrometer from Mahr.

From analog to digital, the entire spectrum of dial gages, dial comparators and dial test indicators. Easy handling, wireless (optionally), and highly accurate. Perfect for efficient use in manufacturing.

A clear digital display, robust construction and high Mahr accuracy characterize our digital dial gages. The range includes measuring instruments for all applications. Various interfaces for data transfer and a high protection rating up to IP 54 leave no demands unfulfilled.

Высокая чувствительность и точность благодаря надежному креплению измерительных осей, прецизионному передаточному механизму и измерительному стержню, устанавливаемому с высокой точностью

Высокая чувствительность и точность благодаря надежному креплению измерительных осей, прецизионному передаточному механизму и измерительному стержню, устанавливаемому с высокой точностью

Compared to analog dial indicators, Millimess dial comparators have even more precise components, providing better measuring accuracy and a much improved hysteresis error. These advantages are particularly evident in runout tests, straightness and flatness measurements and comparative measurements.

The high-precision inductive Millimess dial comparators are capable of digital increments of up to 0.2 μm. User-friendly operating functions such as tolerance monitoring, minimum or maximum recording for dynamic measurements, a combined numerical and scale display and simple data transfer make it an indispensable precision measuring instrument.

Чувствительное, оптимизированное с помощью ЭВМ средство измерения обеспечивает максимальную надежность и точность. Приборы, предназначенные для использования в жестких производственных условиях, оснащены циферблатом с закаленным минеральным стеклом, превосходно защищенным от царапин и повреждения, и уплотнением, обеспечивающим надежную защиту от проникновения жидкостей.

An easy-to-read digital display, the robust design and high Mahr accuracy characterize our digital dial test indicators.

Mahr 3D measuring probes for NC machines, machining centers and eroding machines shorten setup and downtimes. Perfect for accurately contacting reference edges on workpieces and fixtures.

Whether Integrated Wireless, external wireless modules, USB, Opto RS232, or Digimatic: Regardless of which interface standard you use, MarConnect will always provide the best connection.

Many Mahr precision gages have a data output with MarConnect interface. Regardless of which interface standard you use, (USB, Opto RS232 or Digimatic), MarConnect will always provide the best connection.

Семейство беспроводных приборов Mahr Wireless гарантирует точность результатов измерения и неограниченную мобильность. Современный и простой способ измерения без ограничений проводных технологий.

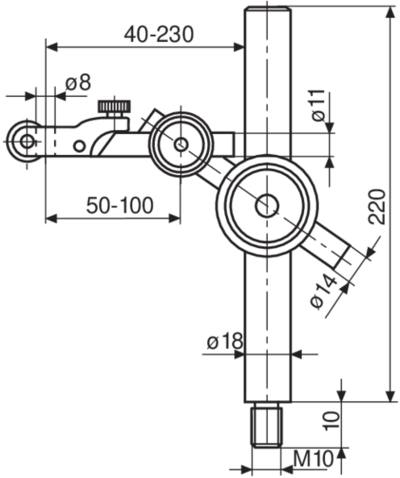

MarStand measuring tripods, measuring tables and radial run-out gages offer high stability, the basis for precise measuring results. They offer the necessary support for your dial indicators, dial comparators, dial test indicator measuring devices and measuring probes.

Measuring tripods provide the basis for precise measuring results due to their stable design. They offer the necessary support for your dial indicators, dial comparators, dial test indicator measuring devices and measuring probes.

Стойки и кронштейны MarStand используются для создания индивидуальных решений, обеспечивающих высокую устойчивость конструкции, что является необходимым условием для получения точных результатов измерения. Они предоставляют необходимые средства для проверки индикаторов часового типа, измерительных головок, рычажно-зубчатых индикаторов и измерительных щупов.

Measuring tables combine a precise and level measuring table, a stable measuring column and strong arm parts. MarStand measuring tables provide the basis for precise measuring results due to their extra stable design.

Radial run-out gages are the simplest method of detecting positional and form errors on shafts in a close-to-production environment. Due to the variety of models, the robust MarStand radial run-out gages form the basis for a wide range of workpiece requirements and precise measuring results.

Test plates made of hard granite are the perfect surface for your height measurement instruments due to the plates’ high strength and dimensional stability.

Using indicating gages as comparative gages make the perfect tool for precision measurements in manufacturing. Setting the gage to a reference standard reduces the deviation margin and minimizes the influence of temperature fluctuations on the measurement result.

Прецизионные индикаторные скобы — это идеальные приборы для точного измерения цилиндрических деталей, таких как валы, болты/шпильки и стержни. Особенно хорошо они подходят для быстрой и безопасной проверки серийных деталей. Быстрое и точное считывание линейных размеров с помощью измерительной головки.

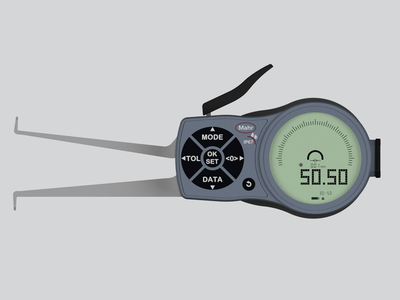

Inner measuring devices are the perfect tools for precisely measuring the diameter, roundness and conicity of holes.

Наши толщиномеры представляют собой надежные и простые приборы для быстрого измерения параметров различных пленок, листов и пластин.

Когда обычные измерительные приборы, такие как штангенциркули или микрометрические нутромеры, невозможно использовать из-за геометрических особенностей детали, идеальным решением станут индикаторные приборы реечного типа!

Our depth gages offer a robust and simple range for particularly fast depth measurements. The 8mm mounting shaft allows the use of dial indicators, dial comparators and probes according to the measuring task.

Universal measuring instruments are the perfect partners for precision measurements in production, because the comparison measurement to a reference standard minimizes the influence of temperature fluctuations on the measurement result.

No matter whether gear, thread, taper or recess: Multimar universal measuring instruments are an ideal solution for almost all internal and external measurements for which standard measuring instruments are not suitable. A choice of basic units and an extensive range of accessories are available.

Точная регулировка приборов для измерения внутренних и наружных размеров. Приборы для настройки 844 S оснащены всем необходимым для выполнения любой измерительной задачи, в том числе и для приборов большой длины.

No matter whether centering shoulders, narrow collars or recesses: The Multimar 36B universal measuring instruments are an ideal solution for almost all inner and outer measurements. A choice of basic units and an extensive range of accessories are available.

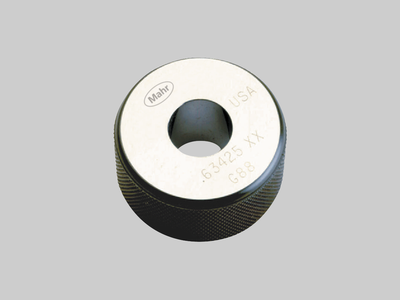

Вы должны быть уверены в установочных мерах и приборах Mahr, ведь они служат основой для получения точных результатов измерений.

Trust in Mahr’s setting standards - because they are the basis for precise measuring results.

Mahr gage blocks ensure that you have high-quality reference and working standards at your disposal. Choose from four tolerance classes and two materials to suit the requirements of your workshop, production or quality assurance.

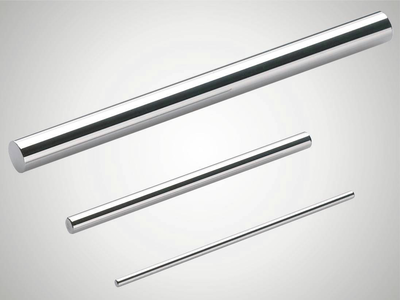

Mahr pin gages are available in three tolerance classes and various designs. Choose the device to suit the requirements of your workshop, production or quality assurance.

The requirements for electrical length measuring instruments are just as varied as their applications. Excellent reliability, precision and simple operation are called for.

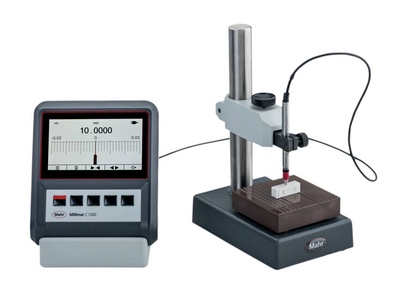

The requirements for electrical length measuring instruments are just as varied as their applications. Excellent reliability, precision and simple operation are called for. Millimar compact and column measuring instruments meet these requirements.

Millimar length measuring instruments are compact, robust, and easy to use. They are versatile evaluation and indicating instruments for measuring tasks of manageable complexity in the production area and in the measuring room.

Measurement results are displayed on 101 three-color LEDs and can easily be read from a distance. If the programmable warning and tolerance limits are exceeded, the segments change color from green to yellow or red.

Разнообразные сочетания модулей и программного обеспечения позволяют создать рабочую среду и инструменты с высочайшей степенью адаптации к вашим требованиям.

Smart and universally applicable software for complex measurement tasks in the manufacturing sector

Millimar transducers are the most important components of a measuring chain. Their characteristics determine the quality of the entire measurement. Depending on the application, various technologies are available for this purpose. For example, Millimar inductive measuring probes: These products are rugged, versatile and attractively priced.

No matter whether thickness measurement, radial runout or concentricity: With the inductive probes you can record measured values and deviations independent of shape, support or radial runout deviations. Their great advantage is the large linearity range and the relative insensitivity to interference. The probes are mainly used for comparative measurements in production, but the specific tasks of the sensor can vary.

Pneumatic length measuring instruments are characterized by their high accuracy and long-term stability. Non-contact measurement with measuring nozzles does not damage the workpieces. Even workpieces that are uncleaned, oiled, lubricated or coated in lapp

Millimar length measuring instruments are compact, robust, and easy to use. They are versatile display and evaluation devices for measuring tasks of manageable complexity in the production area.

Measurement results are displayed on 101 three-color LEDs and can easily be read from a distance. If the programmable warning and tolerance limits are exceeded, the segments change colors from green to yellow or red.

The Millimar pneumatic measuring devices quickly and accurately record dimensional deviations. It has proven itself for many years in the industrial production and measuring room.

For measurement and evaluation on the go.

Non-contact measuring, using pneumatic measuring rings, no damage to the workpieces.

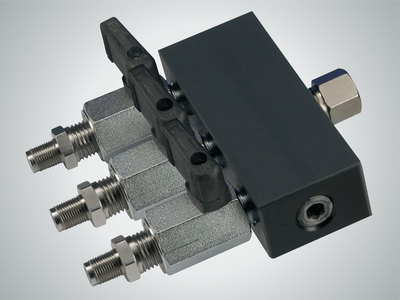

Adapt the measuring station to your measuring task with the accessories for air measuring technology.

Trust in Mahr’s setting standards - because they are the basis for precise measuring results

Setting of pneumatic measuring instruments (nozzle ring gages) Meticulously hardened, aged, ground and lapped.

Setting of pneumatic measuring instruments (nozzle plug gages) Meticulously hardened, aged, ground and lapped.

Want to aim high with your measurements? Digimar is the one for you!

For scribing and marking workpieces in the workshop. Easy measurement of heights and distances.

Easy measurement of heights and distances between bores, surfaces and edges. Suitable for scribing and marking workpieces with additional accessories.

Touch operation, ergonomic handling and a wide range of evaluation options: This is what the Digimar 817 CLT height measuring device stands for.

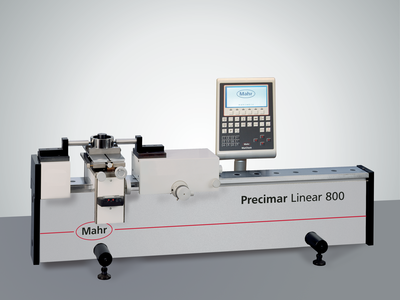

Precision length metrology stands for high-precision dimensional metrology – for both absolute and relative measurements.

Простые в использовании универсальные приборы для измерения длины и настройки средств измерения в производственных условиях

Простые в использовании универсальные приборы для измерения длины и настройки средств измерения в производственных условиях

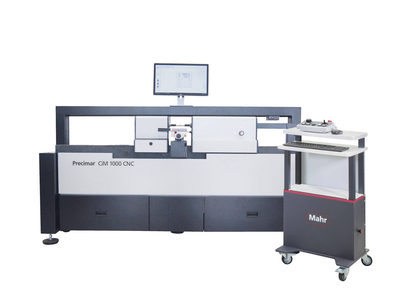

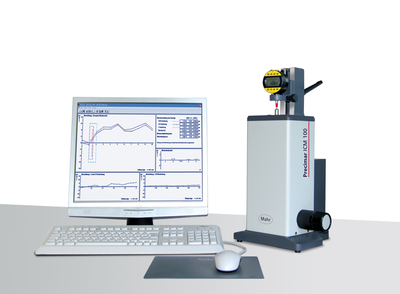

Due to the wide product range from the simple gage block test stand, fully automatic dial gauge test stand, and the ULM devices to the ultra-precise and partially automated CiM universal measuring machine, Mahr always offers a practical solution for production, measuring rooms and calibration laboratories. In other words: Maximum precision combined with extremely efficient measuring processes.

Классические приборы ULM или приборы PLM и CiM с электроприводом. Универсальные приборы Mahr для измерения длины — это удобство, скорость и надежность измерений с минимальной неопределенностью.

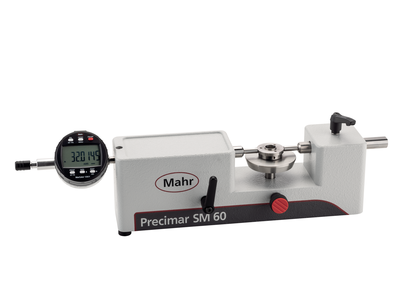

Полуавтоматическая и полностью автоматическая проверка индикаторов часового типа, рычажно-зубчатых индикаторов, измерительных головок и щупов, обеспечивающая эффективность и точность.

Полуавтоматическая и полностью автоматическая проверка индикаторов часового типа, рычажно-зубчатых индикаторов, измерительных головок и щупов, обеспечивающая эффективность и точность.

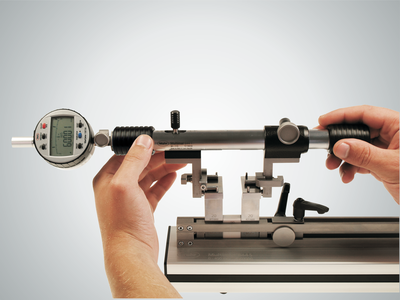

Manual testing of dial gages, dial test indicators and comparators - easy and precise

Trust in Mahr gage block comparators - because they are the basis for the precise testing of your standards

Microscopes are used in almost all industries for the quick inspection of distances, radii, and angles. In the laboratory or close to production.

Измерительные микроскопы

Stereo zoom microscopes with high-quality lens for bright, sharp three-dimensional images. Binocular or trinocular with additional use of digital cameras.

Surface metrology for industry and research

Structured functional surfaces with strict tolerances require high-precision measuring systems that record the topography of a workpiece or object over a short area in a minimum of time.

Contour measurement technology is used to determine rough shape deviations.

Precisely measure contours with optical measuring instruments

Contour and roughness measurement combined: The professional allrounder

Contour and roughness measurement combined: The professional allrounder

2D/3D Contour measurement as well as roughness measurement acc. to ISO 25178 / ISO 4287

3D surface metrology for industry and research

Measure everywhere with mobile measuring devices!

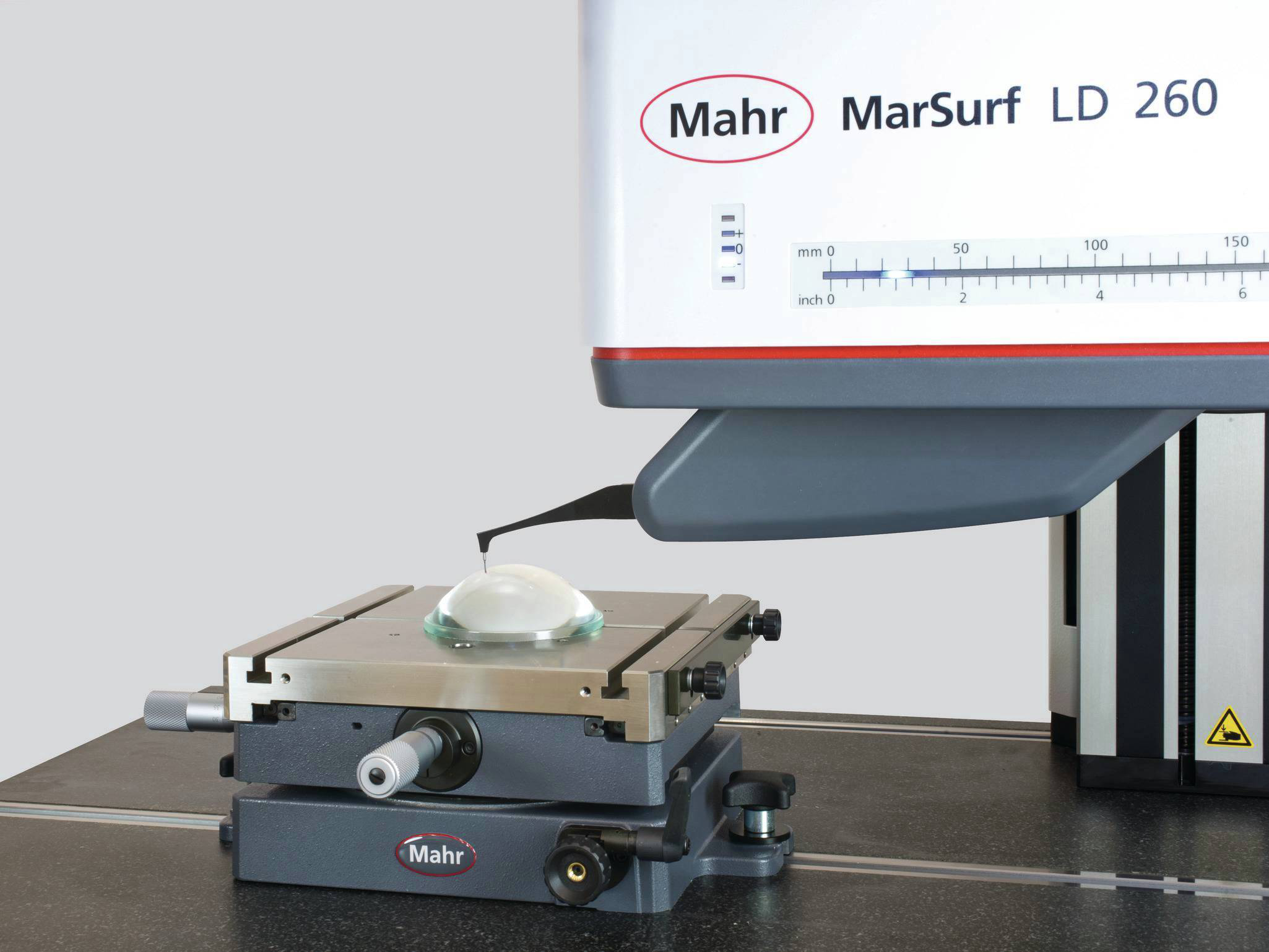

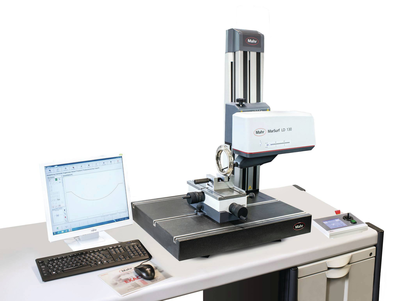

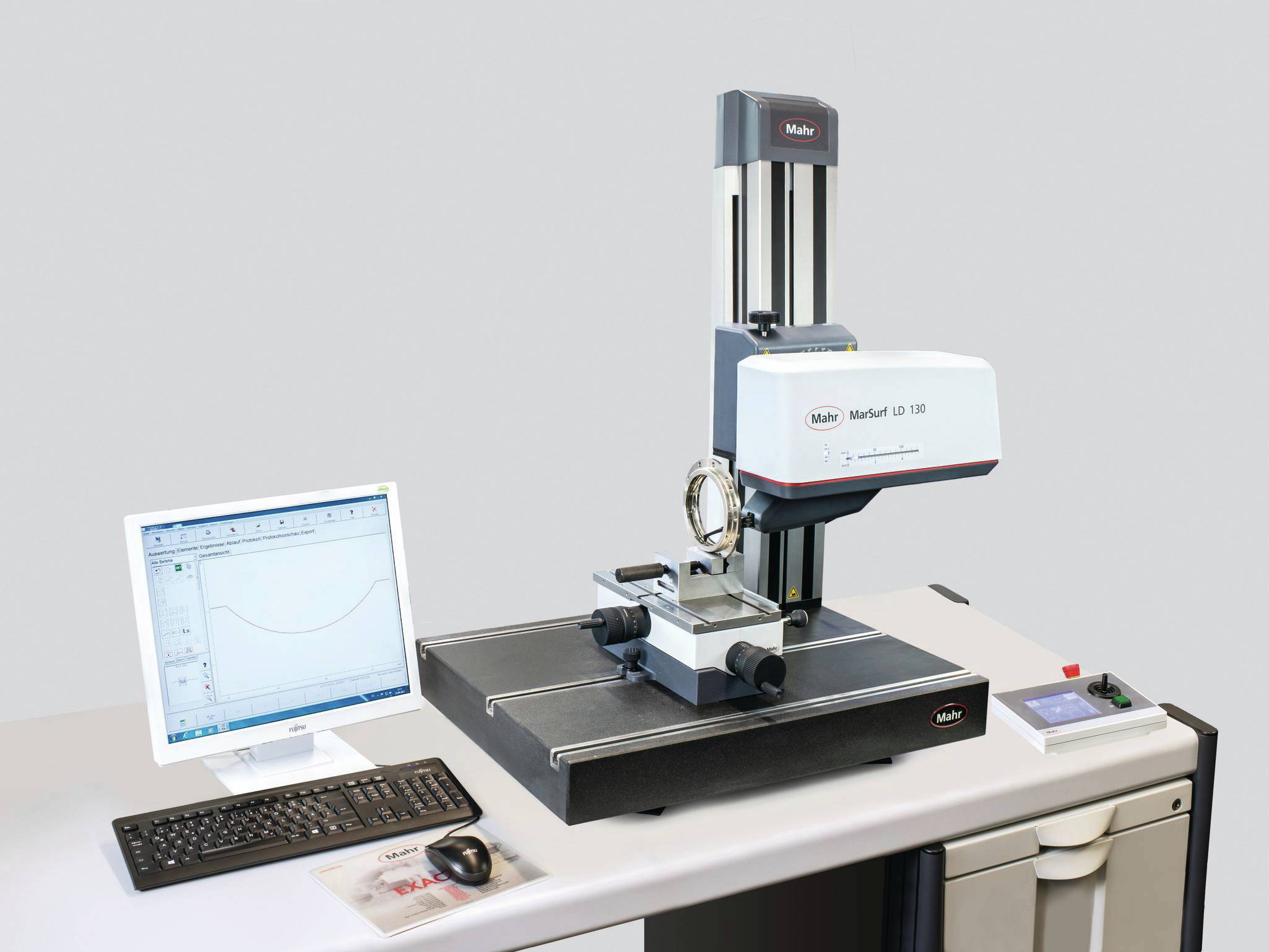

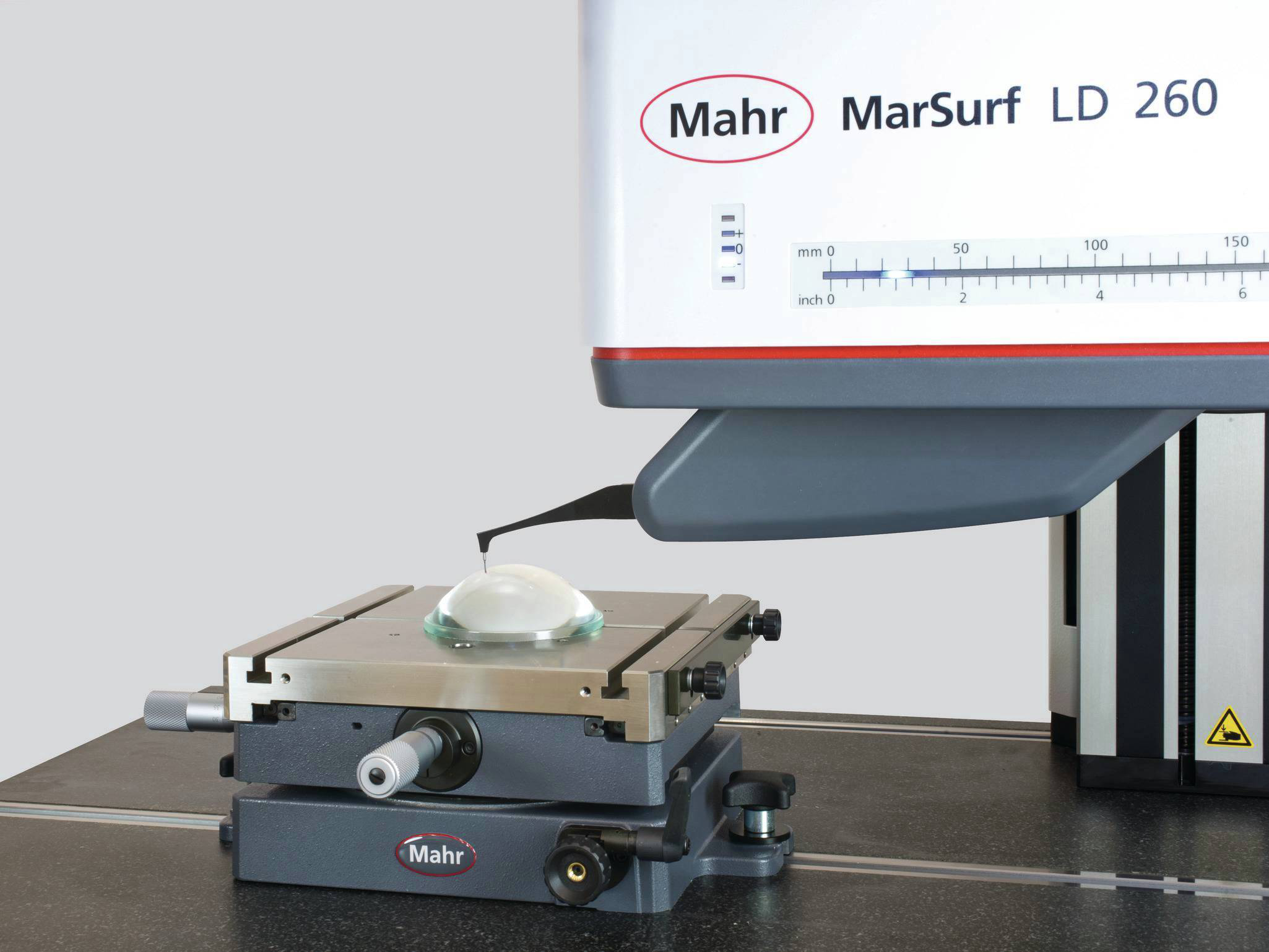

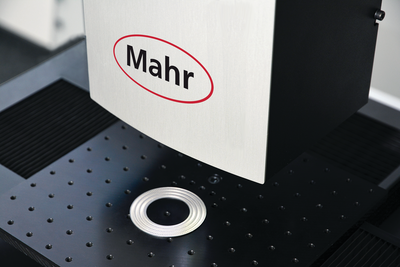

Measuring stations for the measurement of high-precision lenses

When standard solutions are no longer enough: Individual customized solutions

Structured functional surfaces with strict tolerances require high-precision measuring systems that record the topography of a workpiece or object over a short area in a minimum of time.

Versatile and powerful in measuring rooms and laboratories

Contour and roughness measurement combined: The professional allrounder

Tactile measuring stations for contour & roughness measurements

2D/3D contour and roughness measurement acc. to ISO 25178 / ISO 4287

3D surface metrology for industry and research

Measure everywhere with mobile measuring devices!

Mobile 3D surface metrology for

use on-site

Mobile measuring instruments let you measure exactly where you need the results.

Measuring stations for the measurement of ultra-high sensitivity lenses

When standard solutions are no longer enough: Individual customized solutions

Metrology

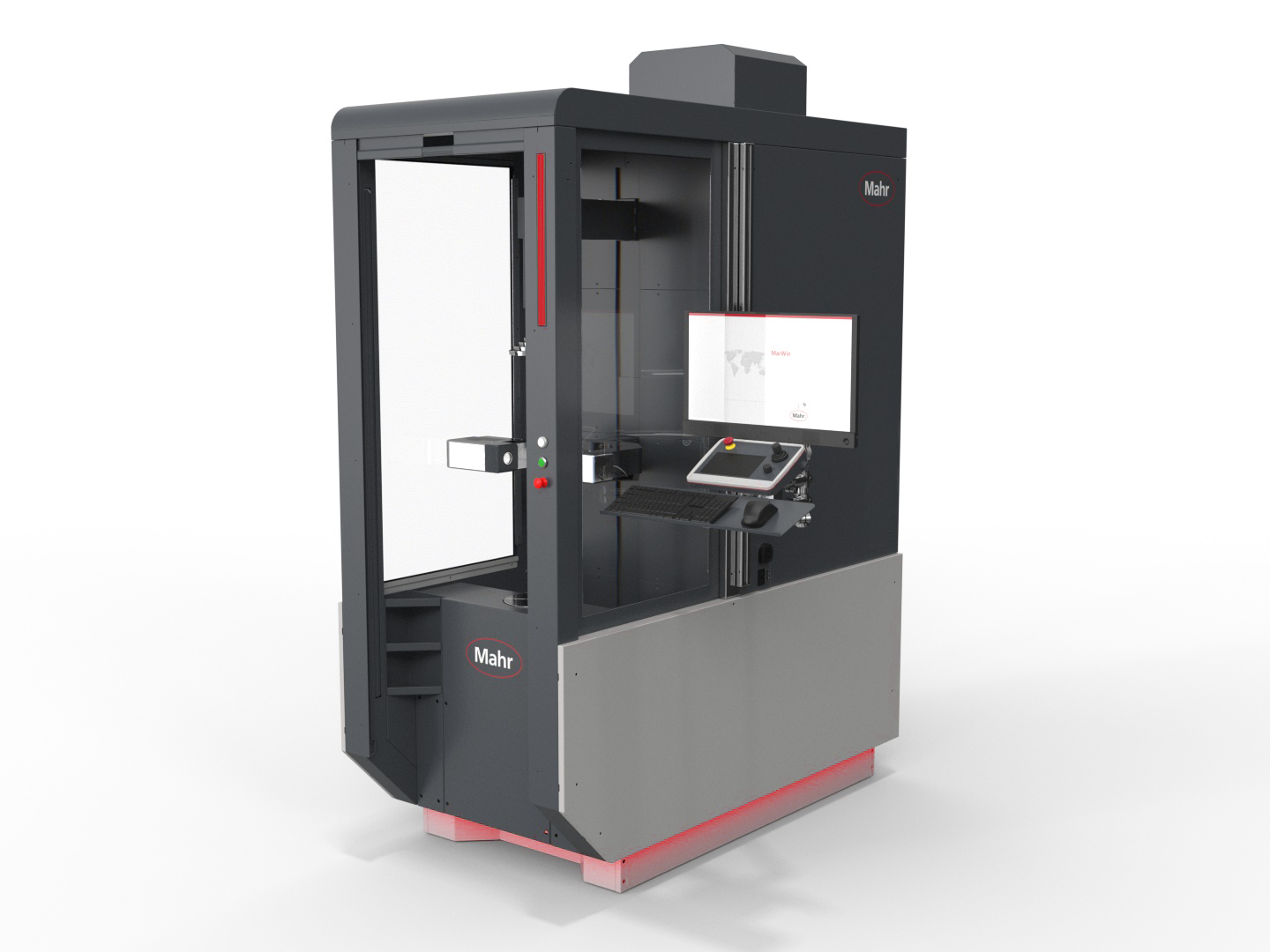

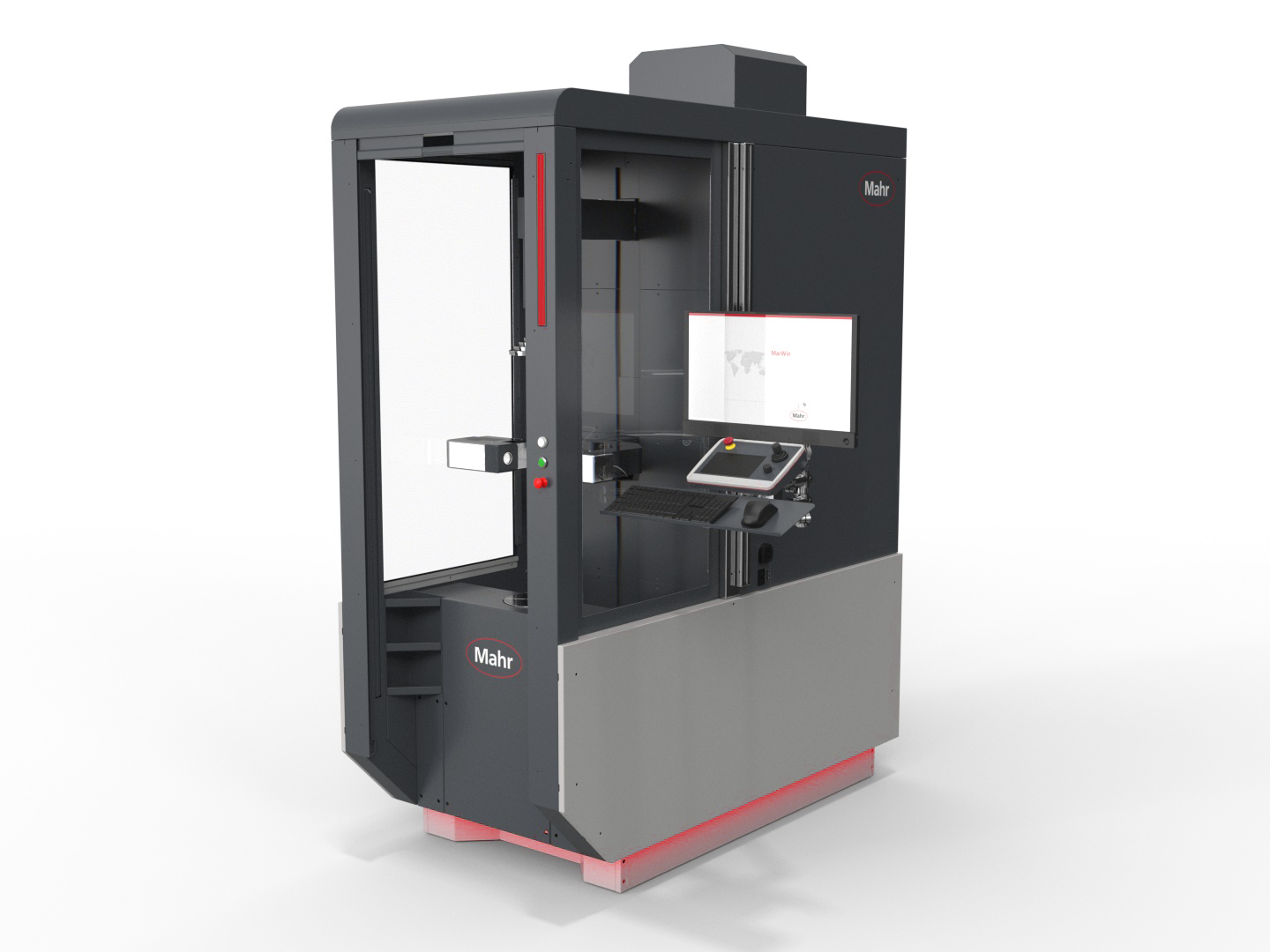

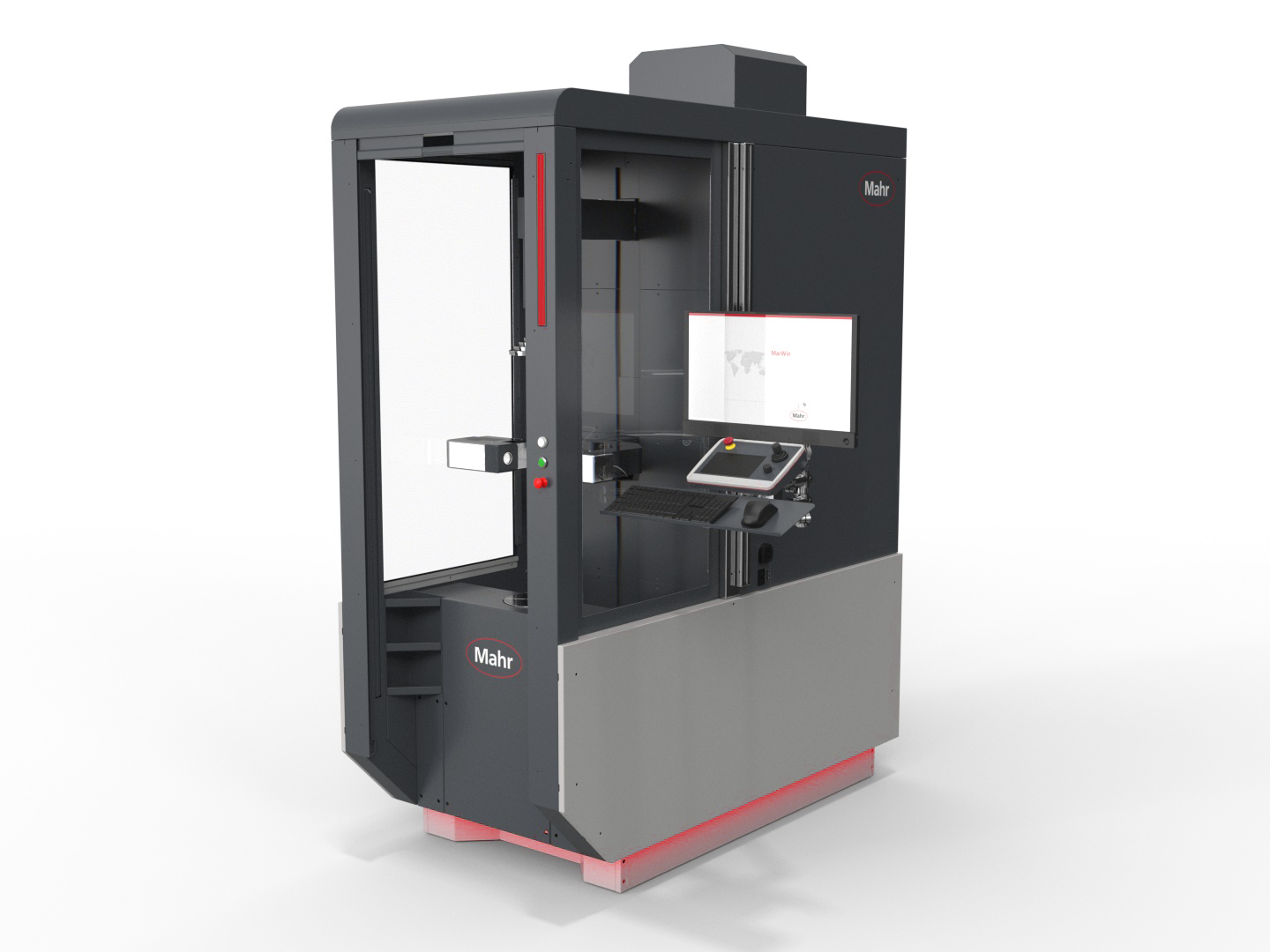

Experience outstanding features combined with extreme flexibility in workpiece size and increase your productivity in the production environment.

Fast optical matrix camera in combination with high-precision touch probes for measuring a large number of features on rotationally symmetrical workpieces. Addition of a fully automatic centering and tilting table for extremely fast, mechanical alignment, flexible clamping options and, for example, internal measurements.

Fast optical matrix camera in combination with high-precision touch probes for measuring a large number of features on rotationally symmetrical workpieces.

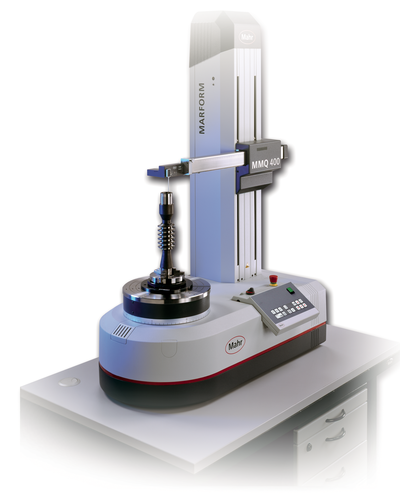

Systems for testing form and position tolerances, such as roundness, flatness, straightness, coaxiality and other measuring tasks. From manual to fully automated.

The device measure features such as roundness, straightness and concentricity simply, cost-effectively, and yet with high precision. Our manual form measuring instruments are suitable for both the measuring room and for measurements close to production.

With our automatic form measuring systems, you reduce your process costs, but without driving up inspection costs - through stable, innovative devices with the highest level of automation, flexibility and accuracy.

Powerful MarOpto Fizeau interferometers can provide contactless measurements on flats and spherical surfaces.

Metrology

Experience outstanding features combined with extreme flexibility in workpiece size and increase your productivity in the production environment.

Fast optical matrix camera in combination with high-precision touch probes for measuring a large number of features on rotationally symmetrical workpieces.

Fast optical matrix camera in combination with high-precision touch probes for measuring a large number of features on rotationally symmetrical workpieces. Addition of a fully automatic centering and tilting table for extremely fast, mechanical alignment, flexible clamping options and, for example, internal measurements.

Optical and tactile shaft measurement systems for use in harsh manufacturing environments. Complete measurement of all common rotationally symmetrical workpieces.

.

Optical and tactile shaft measurement systems for use in harsh manufacturing environments. Complete measurement of all common rotationally symmetrical workpieces.

Universal, fully automatic and robust optical shaft measuring machines for use in harsh workshop environments.

Metrology

Experience outstanding features combined with extreme flexibility in workpiece size and increase your productivity in the production environment.

Fast optical matrix camera in combination with high-precision touch probes for measuring a large number of features on rotationally symmetrical workpieces.

Fast optical matrix camera in combination with high-precision touch probes for measuring a large number of features on rotationally symmetrical workpieces. Addition of a fully automatic centering and tilting table for extremely fast, mechanical alignment, flexible clamping options and, for example, internal measurements.

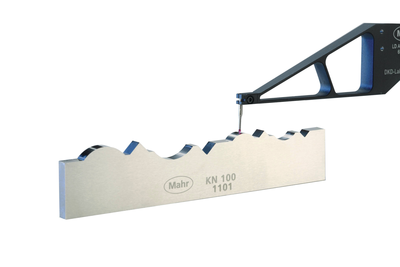

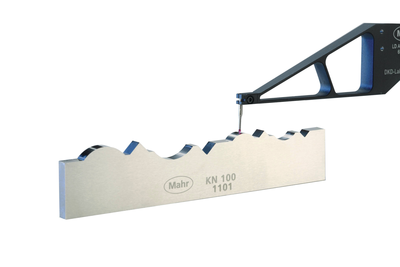

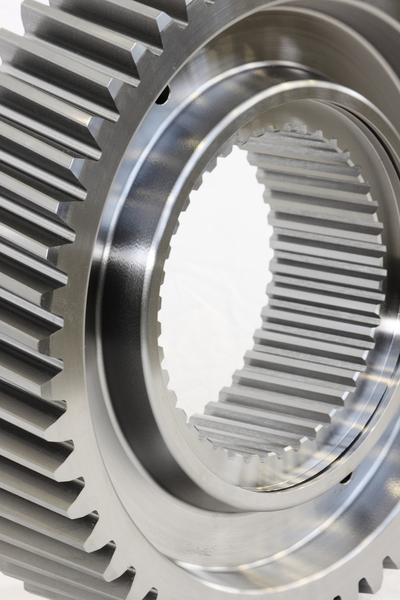

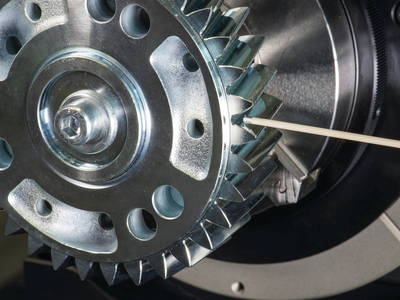

From highly specialized gear analyses to fully integrated series measurement - Mahr is your reliable partner at every level of modern gear and gearbox manufacturing.

MarGear are our flexible gear and cylinder coordinate measuring instruments. Whenever fast feedback is required in the simultaneous production of several different features, MarGear is the right choice. Whether form&position, dimension or high-precision and fully automated inspection of gears: MarGear solves the measurement task.

Measure your product at the point of origin - including rapid feedback to the manufacturing process in order to avoid waste.

Wide range of technologies and products for fast and contactless recording of surfaces and geometries.

Измерительные микроскопы

Determination of roughness, contour and many other surface parameters.

Surface metrology for industry and research

Whether white light or laser interferometer, you will find the right solution for your application.

Powerful MarOpto Fizeau interferometers can provide contactless measurements on flats and spherical surfaces.

Minimal roughness accurate to the nanometer

Optical analysis of surface topographies and geometries

Refurbished systems in proven Mahr quality

Speed up measurement processes, prevent incorrect measurements

The portfolio of the customer from Baden-Württemberg includes quick-connect couplings for low, medium and high-pressure applications. The components are made of brass, stainless steel, steel or plastic, are manufactured in countless variants and are used in aerospace, on the high seas, underwater, in road traffic or in classic manufacturing operations. The couplings are assembled from several individual components and cut to size according to customer requirements. Bores are then required at various points – for example, to make cleaning connections for endoscopes or breathing air technology. These are extremely small holes between three and five millimeters. The tolerances are minimal; each part must fit perfectly. For this reason, the quality technicians always measure the inner contours of the narrow seal recesses as well as their position, width and inner diameter with great precision. In addition to various valve designs – free passage, one-sided and two-sided shut-off, and low-leakage – the manufacturer also offers accessories such as fittings, hoses, or blow-out guns for the couplings.

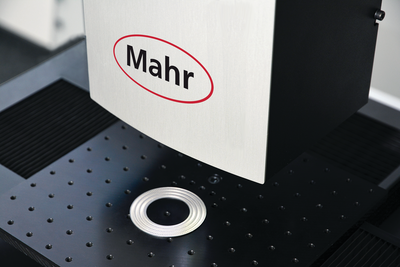

Solution by chance

Previously, these measurements required a great deal of effort: to determine the inside diameter exactly, employees had to make a cut and then analyze it manually with gages and handheld measuring devices. This took up to 15 minutes per cut. One day, during a sampling session, a supplier mentioned to the quality technician the keyword "contourograph", which would exactly fit the measuring tasks. The latter researched for such a device and found out that one of the most renowned manufacturers of such devices, Mahr in Esslingen, was less than half an hour's drive away from their own company. Mahr was already well known through handheld gages, outside micrometers and other tools that were used on a daily basis. So the quality technician promptly arranged an appointment at the Esslingen technical center, to which the team from the coupling manufacturer took various test pieces.

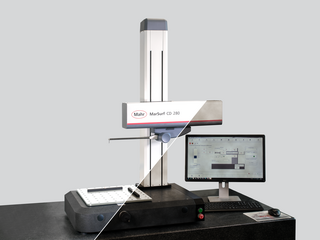

A measurement effort of only a few seconds

On site, the shortlist quickly fell on the MarSurf CD 140: This conturograph has a measuring range of up to 70 millimeters, which can be extended to 100 millimeters thanks to the extra-long probe arms. The probe arm can be changed without tools thanks to the magnetic probe arm holder, which eliminates the need for recalibration. "Stylus recognition takes place via an integrated chip. It speeds up measurement processes and prevents incorrect measurements," explains Antje Zapfe, Global Account Manager Automotive at Mahr. The company initially decided to rent the device on a trial basis. But just three months later, they were so convinced by the Mahr contour graph that the purchase contract was signed in November 2021 and the device is now permanently used in their own measuring room. Measuring with the MarSurf CD 140 is relatively intuitive, almost self-explanatory, according to the customer, who also praises the teach-in function. The device is also frequently and gladly used by colleagues from the production department. Its great advantage is the great time saving: internal contours can be traced directly and thus cutting and measuring can be carried out in just one step and in a few seconds.

Optimally also determine roughness

The large mounting plate with a 50-millimeter bore and pluggable guide stops also provide a great deal of flexibility in handling. Positioning speeds are up to 200 millimeters per second on the X axis, around 25 times faster than on the model's predecessors. The Z-axis of the MarSurf CD 140 is fully CNC-capable and up to five times faster than usual on the market. "Optionally, the device can be expanded to include roughness value determination from Rz 2 μm," adds Mahr product manager Martin Adler. The smallest probe in the range, with a length of 2.8 mm, is now in continuous use at the customer's site as it perfectly detects the minute bores. In order to further simplify the measuring procedure, the manufacturer of the quick coupling systems plans to invest in additional clamping probes in the near future, into which the parts are simply inserted before the program starts. In this way, the team hopes to save further time in the future, especially for cutting patterns.