Ölçüm odasında, üretimde, gelen mallarda ve geliştirme alanında kalite kontrol için yüksek kaliteli metroloji.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

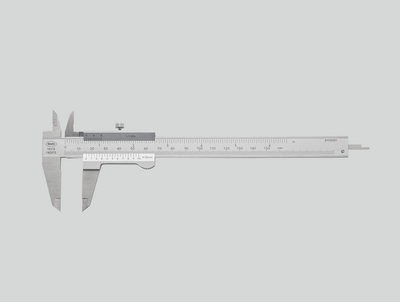

Mahr'dan yenilikçi el tipi ölçüm ekipmanları: Kumpaslar, mikrometre vidaları ve analog indikatörler #96, analogdan dijitale entegre kablosuz aktarımlı modellere. Mahr'ın karşılaştırmalı ölçüm aletleri ve referans standartları vazgeçilmezdir

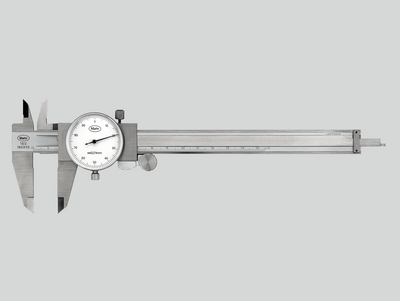

Analogdan dijitale, her çeşit kumpas yelpazesi. Kolay kullanım, kablosuz ve son derece hassas. Üretimde verimli kullanım için mükemmel.

Güvenli, okunması kolay dijital ekran, modern tasarım ve her zamanki Mahr hassasiyeti dijital kumpaslarımızın ayırt edici özelliğidir. Ürün gamında, tüm uygulamalar için ölçüm aletleri bulunur. Veri aktarımı için çeşitli arabirimler ve IP 67'ye kadar koruma derecesi ile karşılanmadık talep kalmaz.

Skalayı korumak ve en yüksek hassasiyeti sağlamak için yansıma önleyici okuma ünitesi, sertleştirilmiş çelik, yükseltilmiş kılavuzlar. Klasik nonius kumpas ile Mahr'dan kaliteli kumpas özellikleri.

Uzun süreli hassasiyet için büyük, yüksek kontrastlı kadran ve darbeye karşı korumalı ölçüm aleti. Hızlı ve güvenli okuma için denenmiş ve test edilmiş mekanik tasarım.

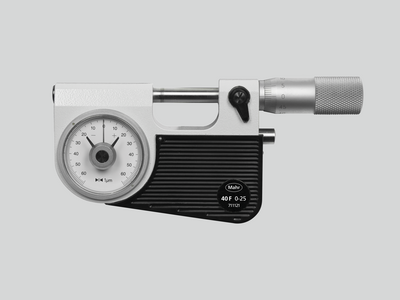

Çeşitli tasarımlarda maksimum hassasiyet. Mahr'ın mikrometre vidaları geleneksel mekanik, dijital ve kablosuz versiyonlarda mevcuttur.

Net dijital ekran, modern tasarım ve her zamanki Mahr hassasiyeti dijital dış mikrometrelerimizin öne çıkan özellikleridir. Ürün gamında, tüm uygulamalar için ölçüm aletleri bulunur. Veri aktarımı için çeşitli arabirimler ve IP 65'e kadar yüksek koruma derecesi ile karşılanmadık talep kalmaz.

Yansıma önleyici okuma ünitesi, ısı yalıtım plakaları ve maksimum duyarlılık için hassas topraklanmış mil. Mahr'dan kaliteli mikrometre özellikleri.

Seri parçaların (mil, cıvata, şaft) güvenilir ve hızlı testi için özellikle uygundur. Boyutsal hassasiyet, analog komparatörde bir bakışta tanınır ve okunur.

2.500 mm'ye kadar büyük çapları ve test mesafelerini ölçmek için uygundur

Skalalı veya dijital ekranlı veya tabanca tipi kabzalı hızlı ölçüm aleti olarak mevcuttur. Mahr 3 noktalı iç ölçüm cihazları, otomatik merkezleme sayesinde her zaman güvenilir ölçüm sonuçları sağlar.

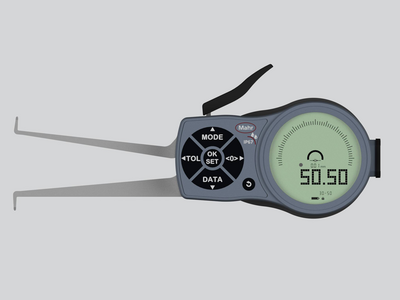

Analogdan dijitale, tüm kadranlı mastar, analog komparatör ve kadran testi indikatörleri yelpazesi. Kolay kullanım, kablosuz (isteğe bağlı), ve son derece hassas. Üretimde verimli kullanım için mükemmel.

Net dijital ekran, sağlam yapı ve yüksek Mahr hassasiyeti, dijital kadranlı mastarlarımızı niteler. Ürün gamında, tüm uygulamalar için ölçüm aletleri bulunur. Veri aktarımı için çeşitli arabirimler ve IP 54'e kadar koruma derecesi ile karşılanmadık talep kalmaz.

Aşağıdaki özellikler sayesinde yüksek duyarlılık ve hassasiyet: Ölçüm aleti eksenlerinin, hassas dişli çarkların ve pinyonların sağlam montaj bağlantısı, yüksek hassasiyette monte edilmiş ölçüm pimi

Analog kadranlı indikatörlerle karşılaştırıldığında, Millimess kadran komparatörleri daha da hassas bileşenlere sahiptir, bu da daha iyi ölçüm hassasiyeti ve çok daha iyi bir histerezis hatası sağlar. Bu avantajlar özellikle kaçıklık testlerinde, doğruluk ve düzlük ölçümlerinde ve karşılaştırmalı ölçümlerde belirgindir.

Yüksek hassasiyetli endüktif Millimess analog komparatörler 0,2 μm'ye kadar dijital artışlar yapabilir. Tolerans izleme, dinamik ölçümler için minimum veya maksimum kayıt, birleşik sayısal ve skala ekranı ve kolay veri aktarımı gibi kullanıcı dostu işletim işlevleri, cihazı vazgeçilmez bir hassas ölçüm aleti haline getirir.

Bilgisayarla optimize edilmiş hassas ölçüm aracı, maksimum güvenilirlik ve hassasiyet sağlar. Zorlu atölye kullanımı için ekran, sertleştirilmiş bir mineral cam panel tarafından çizilmeye veya kırılmaya karşı mükemmel bir şekilde korunur ve ayrıca sızdırmaz, nüfuz eden sıvılara karşı güvenilir koruma sağlar.

The sensitive computer-optimised measuring tool ensures maximum reliability and precision. For rough workshop use, the display is superbly protected. A seal also provides reliable protection against penetrating liquids.

NC tezgahları, işleme merkezleri ve aşındırma tezgahları için Mahr 3D ölçüm probları, kurulum ve arıza sürelerini kısaltır. İş parçaları ve fikstürlerdeki referans kenarlarına hassas şekilde temas etmek için mükemmeldir.

Entegre Kablosuz, harici kablosuz modüller, USB, Opto RS232 veya Digimatic olsun: Kullandığınız arabirim standardından bağımsız olarak MarConnect, her zaman en iyi bağlantıyı sağlar.

Birçok Mahr hassas mastarı, MarConnect arabirimi ile bir veri çıkışına sahiptir. USB, Opto RS232 veya Digimatic; kullandığınız arabirim standardından bağımsız olarak MarConnect, her zaman en iyi bağlantıyı sağlar.

Mahr'ın Kablosuz serisi, tam mobilite ile hassas ölçüm sonuçları sağlar. Kablolu teknolojinin kısıtlamaları olmadan ölçmenin modern ve kolay yolu.

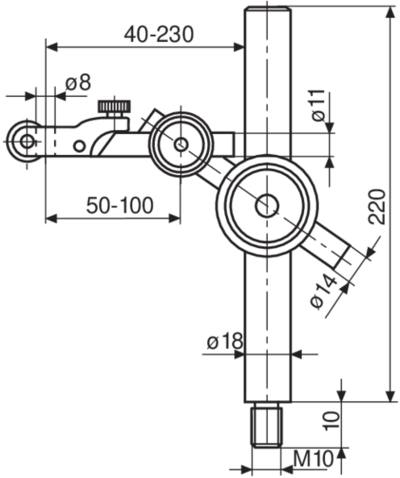

MarStand ölçüm tripodları, ölçüm tablaları ve radyal salgı mastarları, hassas ölçüm sonuçlarının dayanağı olan yüksek stabilite sunar. Analog indikatörleriniz, analog komparatörleriniz, analog test indikatörünüz, ölçüm cihazlarınız ve ölçüm problarınız için gerekli desteği sunarlar.

Ölçüm tripodları, kararlı tasarımları sayesinde hassas ölçüm sonuçları için dayanak sağlar. Analog indikatörleriniz, analog komparatörleriniz, analog test indikatörünüz, ölçüm cihazlarınız ve ölçüm problarınız için gerekli desteği sunarlar.

MarStand direk ve destek tertibatları, bağımsız çözümler için kullanılır ve hassas ölçüm sonuçları için gerekli olan yüksek stabilite sunar. Analog indikatör, analog komparatör, analog test indikatörü ölçüm cihazları ve ölçüm probları için gerekli desteği sunarlar.

Ölçüm tablaları, hassas ve seviyeli bir ölçüm tablasını, sabit bir ölçüm sütununu ve güçlü kol parçalarını birleştirir. MarStand ölçüm tablaları, ekstra kararlı tasarımları sayesinde hassas ölçüm sonuçları için dayanak sağlar.

Radyal salgı mastarları, üretime yakın bir ortamda millerdeki konum ve biçim hatalarını tespit etmenin en basit yöntemidir. Model çeşitliliği nedeniyle, sağlam MarStand radyal salgı mastarları, çok çeşitli iş parçası gereksinimleri ve hassas ölçüm sonuçları için temel oluşturur.

Sert granitten yapılmış test plakaları, plakaların yüksek mukavemeti ve boyutsal kararlılığı nedeniyle yükseklik ölçüm aletleriniz için mükemmel bir yüzeydir.

Gösterge mastarlarının karşılaştırmalı mastarlar olarak kullanılması, üretimde hassas ölçümler için mükemmel bir araçtır. Mastarı bir referans standardına ayarlamak sapma marjını azaltır ve sıcaklık dalgalanmalarının ölçüm sonucu üzerindeki etkisini en aza indirir.

Hassas ibre tutma mastarları, özellikle seri parçalar üzerinde güvenli ve hızlı testler için mil, cıvata ve şaft gibi silindirik parçaların hassas ölçümleri için mükemmel ölçüm araçlarıdır. Boyutsal hassasiyet, komparatörde bir bakışta tanımlanır ve okunur.

İç ölçüm cihazları, deliklerin çap, yuvarlaklık ve konikliğinin hassas bir şekilde ölçümü için mükemmel araçlardır.

Kalınlık ölçerlerimiz, çeşitli film, sac ve levhaların özellikle hızlı ölçümü için sağlam ve basit bir aralık sunar.

İş parçası geometrisi nedeniyle kumpas veya iç mikrometre vidaları gibi yaygın ölçüm aletleri kullanılamıyorsa kumpas mastarları mükemmel çözümdür!

Derinlik mastarlarımız, özellikle hızlı derinlik ölçümleri için sağlam ve basit bir aralık sunar. 8 mm'lik montaj mili, ölçüm görevine göre analog indikatör, komparatör ve probların kullanımına uygundur.

Çok amaçlı ölçüm aletleri, üretimde hassas ölçümler için mükemmel ortaklardır, çünkü bir referans standartla karşılaştırmalı ölçüm, sıcaklık dalgalanmalarının ölçüm sonucu üzerindeki etkisini en aza indirir.

Dişli, diş, konik veya girinti fark etmez. Multimar çok amaçlı ölçüm aletleri, standart ölçüm aletlerinin uygun olmadığı hemen hemen tüm iç ve dış ölçümler için ideal bir çözümdür. Temel ünite seçenekleri ve geniş bir aksesuar yelpazesi mevcuttur.

İç ve dış çap ölçüm aletlerinizi doğru şekilde ayarlayın. 844 S ayar aletlerini kullanırken daha büyük boyutlar için bile her ölçüm görevi amacıyla mükemmel bir donanıma sahipsiniz.

Merkezleme omuzları, dar bilezikler, veya girintiler fark etmez: Multimar 36B çok amaçlı ölçüm aletleri, neredeyse tüm iç ve dış ölçümler için ideal bir çözümdür. Temel ünite seçenekleri ve geniş bir aksesuar yelpazesi mevcuttur.

Mahr'ın ayar standartlarına ve mastarlarına güvenin – çünkü bunlar hassas ölçüm sonuçlarının dayanağıdır.

Mahr'ın ayar standartlarına güvenin, çünkü bunlar hassas ölçüm sonuçlarında referans olarak kullanılır

Mahr mastar blokları, yüksek kaliteli referans ve çalışma standartlarına sahip olmanızı sağlar. Atölyenizin, üretiminizin veya kalite güvencenizin gereksinimlerine uygun dört tolerans sınıfı ve iki malzeme arasından seçim yapın.

Mahr pim mastarları üç tolerans sınıfında ve çeşitli tasarımlarda mevcuttur. Atölyenizin, üretiminizin veya kalite güvencenizin gereksinimlerine uygun cihazı seçin.

Elektriksel uzunluk ölçüm aletlerinin gereksinimleri, uygulamaları kadar çeşitlidir. Mükemmel güvenilirlik, hassasiyet ve kolay kullanım aranır.

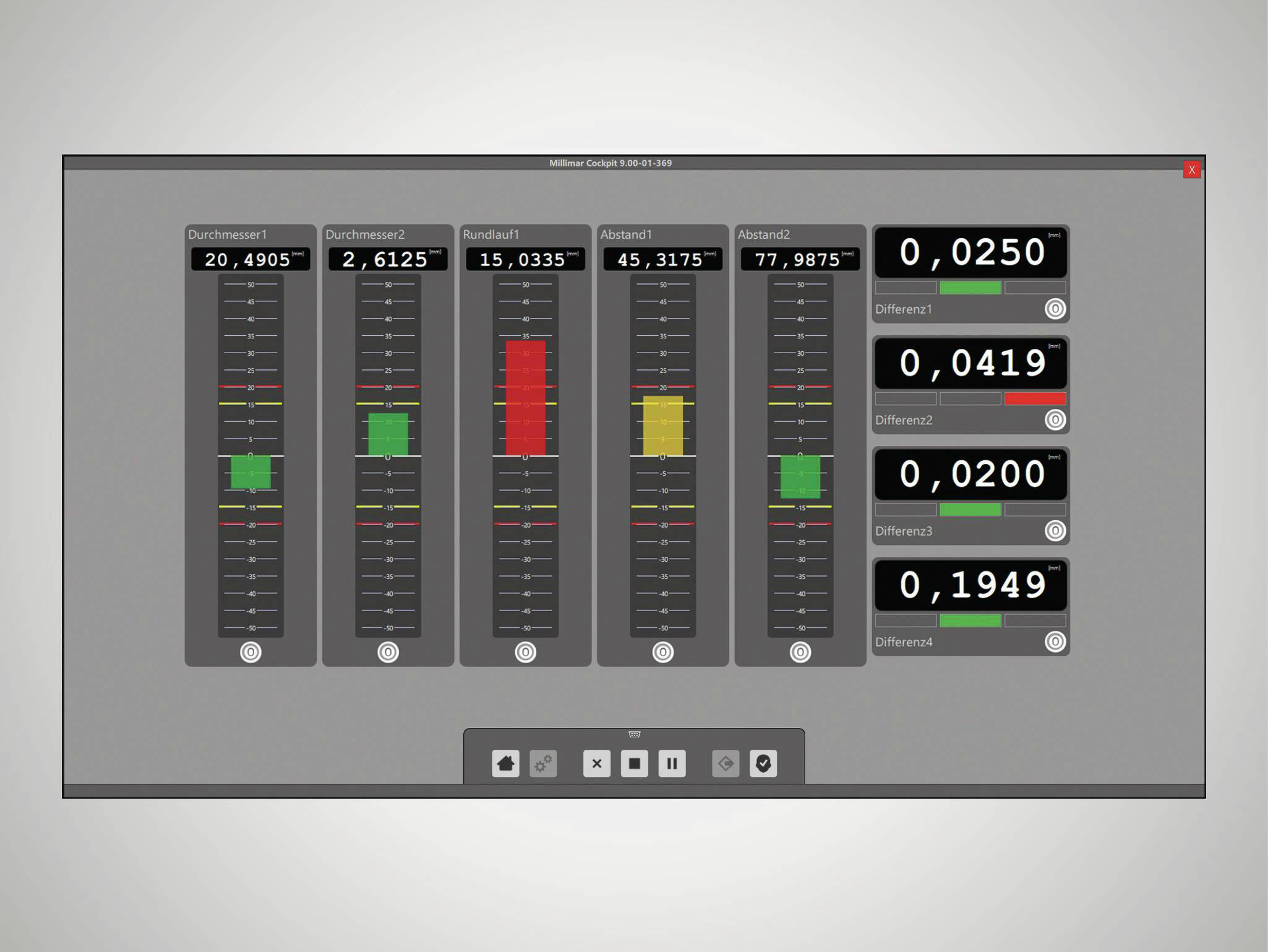

Elektriksel uzunluk ölçüm aletlerinin gereksinimleri, uygulamaları kadar çeşitlidir. Mükemmel güvenilirlik, hassasiyet ve kolay kullanım aranır. Millimar kompakt ve sütun ölçüm aletleri, bu gereksinimleri karşılamaktadır.

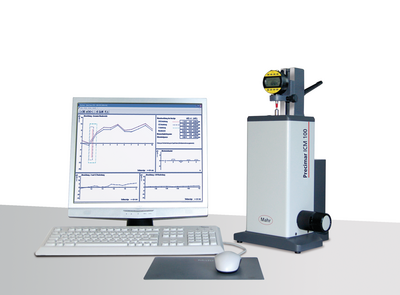

Millimar uzunluk ölçüm aletleri kompakt, sağlam ve kullanımı kolaydır. Üretim alanında ve ölçüm odasında yönetilebilir karmaşıklıktaki görevleri ölçmek için çok yönlü değerlendirme ve görüntüleme aletleridir.

Modüllerin ve yazılımın farklı kombinasyon seçenekleri, çalışma ortamını ve araçları her zamankinden daha farklı olarak tasarlama fırsatı sunar.

Smart and universally applicable software for complex measurement tasks in the manufacturing sector

Millimar dönüştürücüler, bir ölçüm zincirinin en önemli bileşenleridir. Özellikleri, tüm ölçümün kalitesini belirler. Uygulamaya bağlı olarak bu amaç için çeşitli teknolojiler mevcuttur. Örneğin Millimar endüktif ölçüm probları: Bu ürünler dayanıklı, çok yönlü ve cazip fiyatlıdır.

Kalınlık ölçümü, radyal kaçıklık veya eş merkezlilik fark etmez: Endüktif problarla, şekil, destek veya radyal kaçıklık sapmalarından bağımsız olarak ölçülen değerleri ve sapmaları kaydedebilirsiniz. Büyük avantajları, geniş doğrusallık aralığı ve parazite karşı göreceli duyarsızlıktır. Problar esas olarak üretimde karşılaştırmalı ölçümler için kullanılır, ancak sensörün belirli görevleri değişebilir.

Pnömatik uzunluk ölçüm aletleri, yüksek hassaslıkları ve uzun vadeli kararlılıkları ile bilinir. Ölçüm nozulları ile temassız ölçüm, iş parçalarına zarar vermez. Temizlenmemiş, üzerinde madde bulunan, yağlanmış veya kaplanmış iş parçaları bile

Millimar uzunluk ölçüm aletleri kompakt, sağlam ve kullanımı kolaydır. Üretim alanında yönetilebilir karmaşıklıktaki görevleri ölçmek için çok yönlü görüntüleme ve değerlendirme cihazlarıdır.

Ölçüm sonuçları 101 adet üç renkli LED üzerinde görüntülenir ve uzaktan kolayca okunabilir. Programlanabilir uyarı ve tolerans sınırları aşıldığında, segmentlerin renkleri yeşilden sarıya veya kırmızıya değişir.

Millimar pnömatik ölçüm cihazları, boyutsal sapmaları hızlı ve doğru bir şekilde kaydeder. Endüstriyel üretim ve ölçüm odaları konusunda uzun yıllardır kendini kanıtlamıştır.

Hareket halindeyken ölçüm ve değerlendirme için.

Pnömatik ölçüm halkaları kullanarak temassız ölçüm, iş parçalarına zarar vermez.

Hava ölçüm teknolojisi için aksesuarlarla ölçüm istasyonunu ölçümünüze uyarlayın.

Mahr'ın ayar standartlarına güvenin, çünkü bunlar hassas ölçüm sonuçlarında referans olarak kullanılır

Pnömatik ölçüm aletleri ayarı (nozul halka mastarlar) Titizlikle sertleştirilmiş, eskitilmiş, tornalanmış ve bindirilmiş.

Pnömatik ölçüm aletleri ayarı (nozul delik mastarları) Titizlikle sertleştirilmiş, eskitilmiş, tornalanmış ve bindirilmiş.

Ölçümlerinizle yüksekleri hedeflemek ister misiniz? Digimar tam size göre!

Atölyede iş parçalarını çizmek ve işaretlemek için. Yükseklik ve mesafelerin kolay ölçümü.

Practical measurement modes and options: The Digimar 814 C makes typical measurement tasks easy

Touch operation, ergonomic handling and a wide range of evaluation options: This is what the Digimar 816 CLT height measuring device stands for.

Touch operation, ergonomic handling and a wide range of evaluation options: This is what the Digimar 817 CLT height measuring device stands for.

Touch operation, ergonomic handling and a wide range of evaluation options: This is what the Digimar 817 CLT height measuring device stands for.

Hassas uzunluk metrolojisi, hem mutlak hem de bağıl ölçümler için yüksek hassasiyetli boyut metrolojisi anlamına gelir.

Atölye için çok amaçlı, kullanımı kolay uzunluk ölçüm ve ayar cihazları

Atölye için çok amaçlı, kullanımı kolay uzunluk ölçüm ve ayar cihazları

Basit mastar blok test standı, tam otomatik komparatör test standı ve ULM cihazlarından ultra hassas ve kısmen otomatikleştirilmiş CiM çok amaçlı ölçüm makinesine kadar geniş ürün yelpazesi sayesinde Mahr, üretim, ölçüm odaları ve kalibrasyon laboratuvarları için her zaman pratik çözüm sunar. Diğer bir ifadeyle: Maksimum hassaslık ve son derece verimli ölçüm süreçleri bir arada.

İster klasik ULM ister motorlu PLM ve CiM aletleri. Mahr çok amaçlı uzunluk ölçüm makineleri, minimum belirsizlikle kullanıcı dostu, hızlı ve güvenilir ölçüm sağlar.

Analog indikatörlerin, analog test indikatörlerin ölçüm cihazlarının, analog komparatörlerin ve probların yarı otomatik ve tam otomatik testi verimli ve hassas bir şekilde yapılır.

Analog indikatörlerin, analog test indikatörlerin ölçüm cihazlarının, analog komparatörlerin ve probların yarı otomatik ve tam otomatik testi verimli ve hassas bir şekilde yapılır.

Manual testing of dial gages, dial test indicators and comparators - easy and precise

Mahr mastar blok karşılaştırıcılarına güvenin, çünkü bunlar, standartlarınızın hassas şekilde test edilmesinin dayanağıdır

Mikroskoplar, hemen hemen tüm sektörlerde mesafe, yarıçap ve açıların hızlı bir şekilde incelenmesi için kullanılır. Laboratuvarda veya üretim alanına yakın metroloji.

Mikroskoplar, hemen hemen tüm sektörlerde mesafe, yarıçap ve açıların hızlı bir şekilde incelenmesi için kullanılır. Laboratuvarda veya üretim alanına yakın metroloji.

Endüstri ve araştırma için yüzey metrolojisi

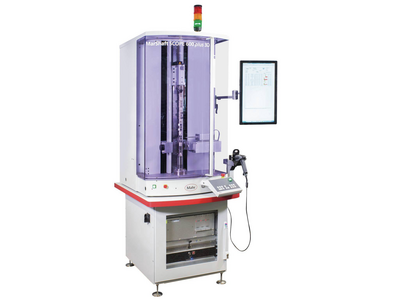

Sıkı toleranslara sahip yapılandırılmış işlevsel yüzeylerde, bir iş parçasının veya nesnenin topografisini kısa bir alanda minimum sürede kaydeden yüksek hassasiyetli ölçüm sistemleri gerekir.

Kaba şekil sapmalarını belirlemek için kontur ölçüm teknolojisi kullanılır.

Optik ölçüm aletleriyle konturları hassas bir şekilde ölçün

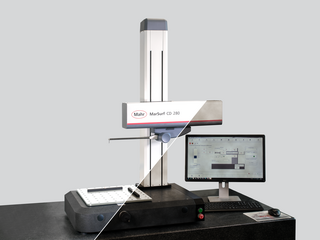

Kontur ve pürüzlülük ölçümü bir arada: Profesyonel çok yönlü

Kontur ve pürüzlülük ölçümü bir arada: Profesyonel çok yönlü

2D/3D Kontur ölçümü ve ayrıca ISO 25178 / ISO 4287'ye göre pürüzlülük ölçüm aksesuarları

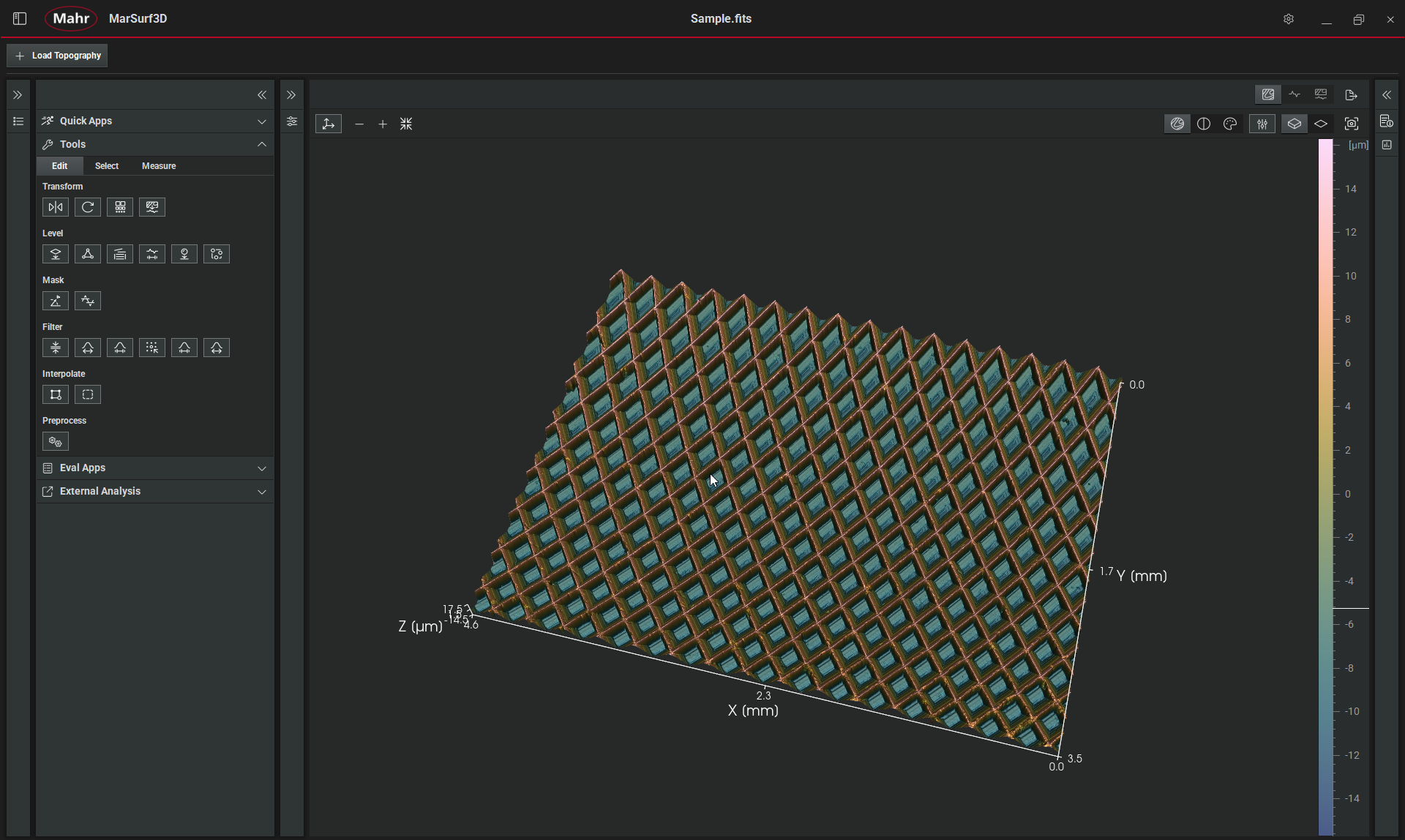

Endüstri ve araştırma için 3D yüzey metrolojisi

Mobil ölçüm cihazları ile her yerde ölçüm yapın!

Yüksek hassasiyetli objektiflerin ölçümü için ölçüm istasyonları

Standart çözümler artık yeterli olmadığında: Bağımsız özelleştirilmiş çözümler

Sıkı toleranslara sahip yapılandırılmış işlevsel yüzeylerde, bir iş parçasının veya nesnenin topografisini kısa bir alanda minimum sürede kaydeden yüksek hassasiyetli ölçüm sistemleri gerekir.

Ölçüm odalarında ve laboratuvarlarda çok yönlü ve güçlü kullanım

Kontur ve pürüzlülük ölçümü bir arada: Profesyonel çok yönlü

Kontur ve pürüzlülük ölçümleri için temaslı ölçüm istasyonları

ISO 25178 / ISO 4287'ye göre 2D/3D kontur ve pürüzlülük ölçüm aksesuarları

Endüstri ve araştırma için 3D yüzey metrolojisi

Mobil ölçüm cihazları ile her yerde ölçüm yapın!

Kullanım için çok yönlü

mobil 3D yüzey metrolojisi

Mobil ölçüm aletleri, sonuçlara tam olarak ihtiyaç duyduğunuz yerde ölçüm yapmanızı sağlar.

Ultra yüksek hassasiyetli objektiflerin ölçümü için ölçüm istasyonları

Standart çözümler artık yeterli olmadığında: Bağımsız özelleştirilmiş çözümler

Metrology

Experience outstanding features combined with extreme flexibility in workpiece size and increase your productivity in the production environment.

Flexible measurement of workpieces that can be clamped between centers

High resolution and very fast matrix camera for measuring a large number of features on rotationally symmetrical workpieces.

Fast optical matrix camera in combination with high-precision touch probes for measuring a large number of features on rotationally symmetrical workpieces.

Flexible clamping options and high-precision alignment using a fully automatic centering and tilting table

High resolution and very fast optical matrix camera for measuring a wide range of rotationally symmetrical workpieces. Addition of a fully automatic centering and tilting table for extremely fast, mechanical alignment and flexible clamping options.

Fast optical matrix camera in combination with high-precision touch probes for measuring a large number of features on rotationally symmetrical workpieces. Addition of a fully automatic centering and tilting table for extremely fast, mechanical alignment, flexible clamping options and, for example, internal measurements.

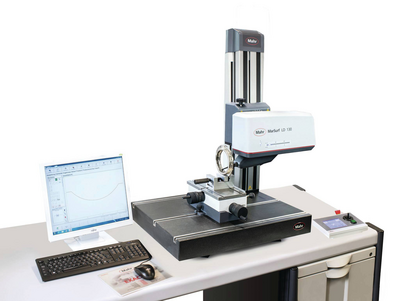

Yuvarlaklık, düzlük, doğrusallık, eş eksenlilik ve diğer ölçüm görevleri gibi form ve konum toleranslarını test etmek için sistemler. Manuelden tam otomatiğe.

Cihaz yuvarlaklık, düzlük ve eş merkezlilik gibi özellikleri kolay, uygun maliyetli ve yüksek hassasiyetle ölçer. Manuel form ölçüm aletlerimiz hem ölçüm odası hem de üretime yakın ölçümler için uygundur.

Otomatik form ölçüm sistemlerimizle, en yüksek otomasyon, esneklik ve hassasiyet seviyesine sahip kararlı, yenilikçi cihazlar aracılığıyla denetim maliyetlerinizi artırmadan süreç maliyetlerinizi düşürürsünüz.

metrology

Experience outstanding features combined with extreme flexibility in workpiece size and increase your productivity in the production environment.

Flexible measurement of workpieces that can be clamped between centers

Flexible clamping options and high-precision alignment using a fully automatic centering and tilting table

Zorlu üretim ortamlarında kullanım için optik ve temaslı mil ölçüm sistemleri. Tüm yaygın döner simetrik iş parçalarının eksiksiz ölçümü.

.

Zorlu atölye ortamlarında kullanım için çok amaçlı, tam otomatik ve sağlam optik mil ölçüm makineleri.

Zorlu üretim ortamlarında kullanım için optik ve temaslı mil ölçüm sistemleri. Tüm yaygın döner simetrik iş parçalarının eksiksiz ölçümü.

Metrology

Experience outstanding features combined with extreme flexibility in workpiece size and increase your productivity in the production environment.

Flexible measurement of workpieces that can be clamped between centers

Flexible clamping options and high-precision alignment using a fully automatic centering and tilting table

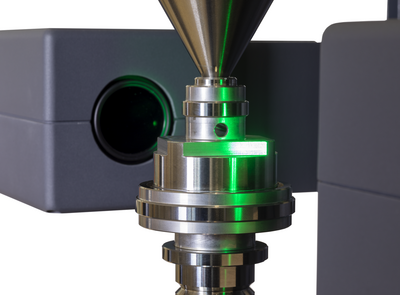

Yüzeylerin ve geometrilerin hızlı ve temassız kaydı için geniş teknoloji ve ürün yelpazesi.

Mikroskoplar, hemen hemen tüm sektörlerde mesafe, yarıçap ve açıların hızlı bir şekilde incelenmesi için kullanılır. Laboratuvarda veya üretim alanına yakın metroloji.

Pürüzlülük, kontur ve diğer birçok yüzey parametrelerinin belirlenmesi.

Endüstri ve araştırma için yüzey metrolojisi

Nanometreye kadar hassas minimum pürüzlülük

Yüzey topografyalarının ve geometrilerinin optik analizi

Surface metrology for industry and research

Surface metrology for industry and research

Kanıtlanmış Mahr kalitesinde yenilenmiş sistemler

3D measuring devices in medical technology

Surfaces increasingly have to exhibit special properties. This is particularly true for medical technology: Implants and prostheses are precisely ground to produce specific roughnesses or smoothnesses. Only in this way can the artificial replacement enable natural movement.

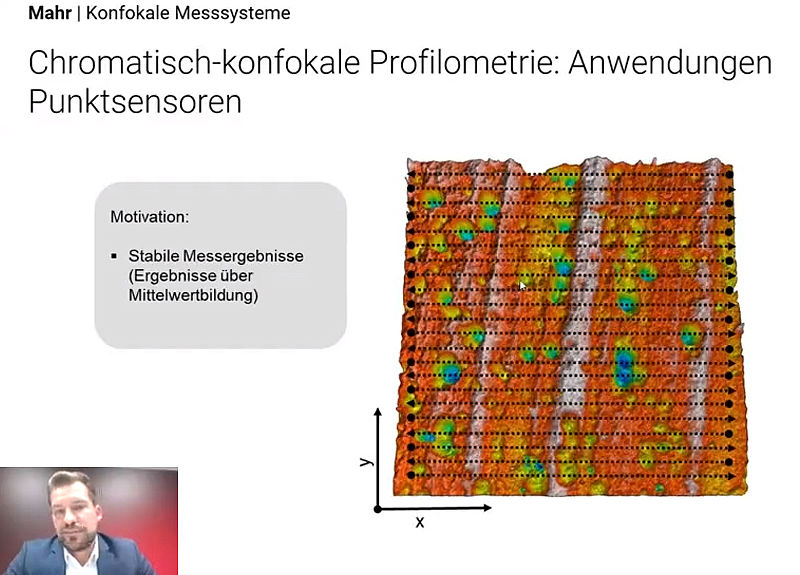

Webinar with practical relevance

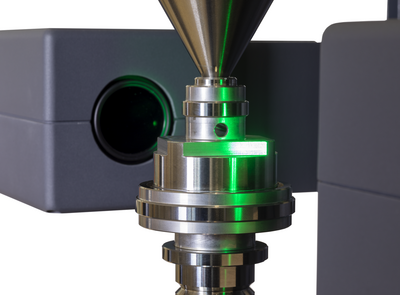

In his presentation, Christopher Wallmann first classifies the various measurement technologies - white light interferometry, confocal microscopes and profilometry - explains their advantages and properties, and highlights Mahr's range of 3D measuring instruments.

However, one focus of his presentation is on the concrete practical relevance: The 3D measuring instruments are used, among other things, for the standard-compliant roughness measurement of catheters, tubes, tools, stents, biosensors as well as joint implants and dental implants. The best thing is to take a look for yourself:

Confocal thread measurement

Using dental implants as an example, Wallmann demonstrates a measurement of thread geometry using a confocal system. On the thread, the geometry including the distances is recorded in a measuring range between 300 and 400 micrometers. "You can also use it to look at texture direction, for example, or to check load-bearing components to make sure that the specifications of the implants are met," Wallmann explains. The geometry measurement of the implant can be recorded areally, as another measurement example shows. The confocal microscope can also be used to measure the topography of crowns, for example to check their wear. Knee joints also play a major role in medical technology, as the trade fair expert explains: On this largest human joint, it is a matter of highly polished surfaces, where roughness measurements with repeat accuracies of <0.2 nanometers are required.

Other industries in which Mahr's measurement technology is used include the automotive industry, and here in particular the areas of car bodies and engines, as well as in materials science, electronics, the semiconductor industry, and in printing and security systems.

Further information

- You want to know more about working on dental implants? Read this article.

- Would you like to contact us? Send us an email at info@mahr.com or use the contact form.