Kvalitní měřicí technika pro kontrolu kvality v měřicí místnosti, výrobě, příjmu zboží nebo v

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Technika měření tvaru a polohy Technika na měření hřídelí Optická měřicí technika Portál použitých strojů

Inovativní ruční měřicí technika od společnosti Mahr: Posuvná měřítka, mikrometry a číselníkové úchylkoměry od analogové po digitální verzi s integrovaným bezdrátovým přenosem. Komparační měřicí zařízení Mahr a referenční etalony jsou pro vaši přesnou měřící techniku pro výrobu nepostradatelné.

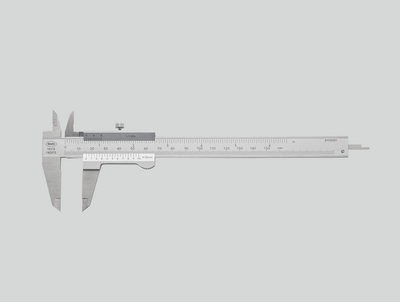

Celá řada posuvných měřítek, od analogových po digitální. Snadné použití, bezdrátová a vysoce přesná. Ideální pro efektivní využití ve výrobě.

Naše digitální posuvná měřítka se vyznačují spolehlivě čitelným digitálním displejem, moderním designem a obvyklou přesností společnosti Mahr. Sortiment zahrnuje měřicí zařízení pro všechny aplikace. Různá rozhraní pro přenos dat a třídy ochrany do IP 67 vyhoví všem nárokům.

Odečet bez odlesků, kalená ocel, zvýšené vodicí dráhy k ochraně měřítka a maximální přesnost. Vlastnosti kvalitního posuvného měřítka společnosti Mahr s klasickým noniem.

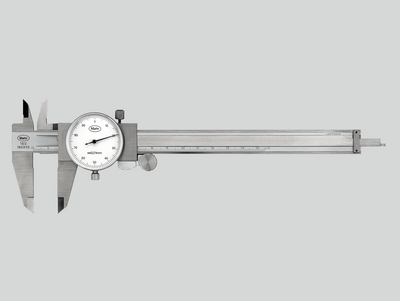

Velký kontrastní číselník a měřicí ústrojí chráněné proti nárazům pro trvalou přesnost. Mechanická klasika pro rychlé a spolehlivé odečtení.

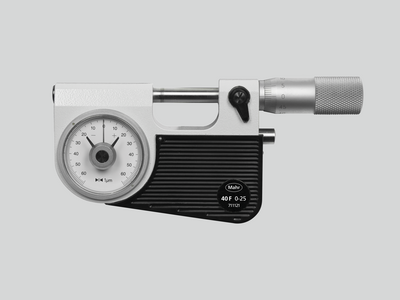

Maximální přesnost v nejrůznějších provedeních. Mikrometry společnosti Mahr jsou nabízeny v klasické mechanické verzi až po digitální a bezdrátovou verzi.

Naše digitální třmenové mikrometry se vyznačují dobře čitelným digitálním displejem, moderním designem a obvyklou přesností společnosti Mahr. Sortiment zahrnuje měřicí zařízení pro všechny aplikace. Různá rozhraní pro přenos dat a vysoký stupeň ochrany do IP 65 vyhoví všem nárokům.

Odečet bez odlesků, tepelně izolační desky a přesně broušené vřeteno pro maximální přesnost. Vlastnosti kvalitního mikrometru společnosti Mahr.

Obzvláště vhodné pro bezpečné a rychlé testování sériových dílů (hřídelí, šroubů, stopek). Rozměrová přesnost se na přesném úchylkoměru rozpozná a odečte na první pohled.

Pro měření velkých průměrů a kontrolu vzdáleností do 2500 mm

Volitelně se stupnicí nebo digitálním displejem, nebo jako vysokorychlostní měřicí zařízení s pistolovou rukojetí. 3bodové přístroje na měření vnitřních rozměrů Mahr vždy poskytují spolehlivé výsledky měření díky automatickému samovystředění.

Celá řada číselníkových úchylkoměrů, přesných úchylkoměrů a páčkových úchylkoměrů, od analogových po digitální. Snadné použití, volitelně bezdrátové a vysoce přesné. Ideální pro efektivní využití ve výrobě.

Bezpečně čitelný digitální displej, robustní konstrukce a vysoká přesnost Mahr charakterizují naše digitální číselníkové úchylkoměry. Sortiment zahrnuje měřicí zařízení pro všechny aplikace. Různá rozhraní pro přenos dat a vysoký stupeň ochrany do IP 54 vyhoví všem nárokům.

Vysoká citlivost a přesnost díky vlastnostem: Robustní uložení os měřicího mechanismu, kola a pastorky s přesným ozubením, vysoce přesné uložené měřicí čepy.

Ve srovnání s analogovými číselníkovými úchylkoměry mají přesné úchylkoměry Millimess ještě přesnější komponenty, lepší přesnost měření a mnohem lepší hysterezi. Tyto přednosti se prokážou především při kontrolách obvodového házení, měření přímosti a rovinnosti nebo u srovnávacích měření.

Vysoce přesné indukční úchylkoměry Millimess dosahují hodnot rozlišení až 0,2 μm. Praktické obslužné funkce, jako je sledování tolerance, minimální nebo maximální záznam pro dynamická měření, kombinované číselné a stupnicové zobrazení a také snadný přenos dat z něj činí nepostradatelné přesné měřicí zařízení.

Citlivý, počítačově optimalizované měřicí ústrojí zajišťuje maximální spolehlivost a přesnost. Pro použití v náročných dílenských podmínkách je displej skvěle chráněn proti poškrábání nebo rozbití krycím sklíčkem z tvrzeného minerálního skla, které je navíc utěsněno proti vniknutí kapalin.

Citlivé, počítačově optimalizované měřicí ústrojí zajišťuje maximální spolehlivost a přesnost. Otočný displej je výborně chráněn pro případ použití v drsných dílenských podmínkách, těsnění se navíc postará o ochranu před vniknutím kapalin.

3D měřicí snímače Mahr pro NC stroje, obráběcí centra a elektroerozivní stroje zkracují vaše přípravné doby a prostoje. Perfektní pro přesné snímání referenčních hran na obrobcích a přípravcích.

Ať se jedná o integrované bezdrátové rozhraní Integrated Wireless, externí rádiové moduly, USB, Opto RS232 nebo Digimatic: Bez ohledu na to, který standard rozhraní použijete, MarConnect se vždy postará o optimální připojení.

Mnoho ručních měřicích zařízení Mahr má datový výstup s rozhraním MarConnect. Bez ohledu na to, který standard rozhraní použijete (USB, Opto RS232 nebo Digimatic), MarConnect se vždy postará o optimální připojení.

Prostřednictvím sortimentu přístrojů s bezdrátovým rozhraním společnosti Mahr si zajistíte přesné výsledky měření při plné volnosti pohybu. Měřte moderně a jednoduše – nenechejte se omezovat technikou s kabelovým připojením

MarStand měřicí stativy, měřicí stoly a zařízení na kontrolu obvodového házení tvoří díky své stabilní konstrukci základ pro přesné výsledky měření. Zde naleznou vaše číselníkové úchylkoměry, přesné indikátory, páčkové úchylkoměry a měřicí snímače nezbytnou podporu.

Měřicí stativy poskytují díky své stabilní konstrukci základ pro přesné výsledky měření. Zde naleznou vaše číselníkové úchylkoměry, přesné indikátory, páčkové úchylkoměry a měřicí snímače nezbytnou podporu.

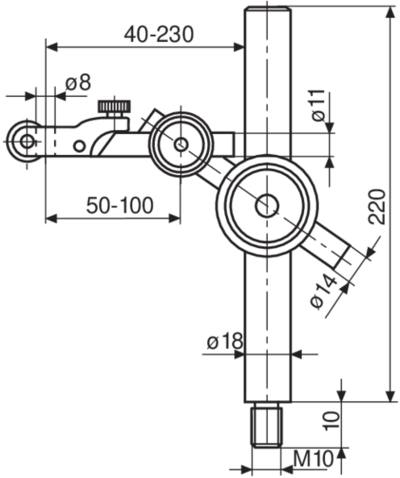

Měřící tyčové mechanismy MarStand se využívají pro individuální řešení a díky své stabilní konstrukci představují základ pro přesné výsledky měření. Zde naleznou číselníkové úchylkoměry, přesné indikátory, páčkové úchylkoměry a měřicí snímače nezbytnou podporu.

Kombinace přesně rovného měřicího stolu, stabilního měřícího sloupu a silných ramen jsou znaky měřicích stolů. Měřicí stojany MarStand představují díky své stabilní konstrukci základ pro přesné výsledky měření.

Zařízení na kontrolu obvodového házení jsou nejjednodušší metodou k určení chyb polohy a tvaru na hřídelích v prostředí souvisejícím s výrobou. Díky rozmanitosti modelů představuje robustní zařízení na kontrolu obvodového házení MarStand základ pro širokou škálu požadavků na obrobky a přesné výsledky měření.

Zkušební desky z tvrdé žuly jsou díky své vysoké pevnosti a tvarové stálosti dokonalým základem pro vaše zařízení na měření výšky.

Jako srovnávací měřicí zařízení jsou indikační měřicí přístroje dokonalým nástrojem pro přesná měření ve výrobě. Nastavení podle referenčního etalonu snižuje rozsah odchylek a minimalizuje vliv teplotních výkyvů na výsledek měření.

Přesné třmenové kalibry jsou dokonalým měřicím zařízením pro přesná měření válcových dílů, jako jsou hřídele, čepy a stopky, zejména pro bezpečné a rychlé zkoušky sériových dílů. Rozměrová přesnost se na přesném úchylkoměru bezpečně rozpozná a odečte na první pohled.

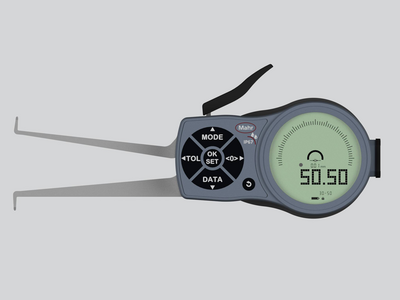

Zařízení na měření vnitřních rozměrů jsou dokonalým nástrojem pro přesná měření otvorů z hlediska průměru, kruhovitosti a kuželovitosti.

S našimi přístroji na měření tlouštěk nabízíme robustní a jednoduché spektrum pro obzvláště rychlé měření fólií, plechů a desek všeho druhu.

Pokud z důvodu geometrie obrobku nelze použít běžná měřicí zařízení, jako jsou posuvná měřítka nebo mikrometry pro měření vnitřních rozměrů, jsou měřicí přístroje se snímacími rameny dokonalým řešením!

S našimi můstky pro měření hloubek nabízíme robustní a jednoduché spektrum pro obzvláště rychlé měření hloubek. S upínací stopkou 8 mm lze použít číselníkové úchylkoměry, přesné úchylkoměry a snímače v závislosti na měřicí úloze.

Univerzální měřicí zařízení jsou jako srovnávací měřicí zařízení dokonalým partnerem pro přesná měření ve výrobě, protože srovnávací měření s referenčním etalonem minimalizuje vliv kolísání teploty na výsledek měření.

Je lhostejné, zda se jedná o ozubení, závity, kužele nebo zápichy: Univerzální měřicí zařízení Multimar nabízejí pro téměř všechna měření vnitřních a vnějších rozměrů, pro která nejsou vhodná standardní měřicí zařízení, optimální řešení. K tomu jsou vám k dispozici různá základní zařízení a obsáhlý sortiment dílů příslušenství.

Přesně nastavte zařízení na měření vnitřních a vnějších rozměrů. S nastavovacími zařízeními 844 S jste optimálně vybaveni pro každou úlohu měření - i pro větší rozměry.

Bez ohledu na to, zda se jedná o středicí okraje, úzké nákružky nebo zápichy: Univerzální měřicí zařízení Multimar 36B nabízejí pro téměř všechna měření vnitřních a vnějších rozměrů optimální řešení. K tomu jsou vám k dispozici různá základní zařízení a obsáhlý sortiment dílů příslušenství.

Důvěřujte etalonům a měrkám Mahr – protože jsou základem pro přesné výsledky měření.

Důvěřujte nastavovacím etalonům Mahr - protože jsou základem pro přesné výsledky měření.

Koncové měrky Mahr představují vysoce kvalitní referenční a pracovní etalony. Vyberte si ze 4 tříd tolerance a 2 materiálů vhodných pro vaši dílnu, výrobu nebo zajištění kvality.

Zkušební kolíky Mahr jsou dostupné ve 3 třídách tolerance a různých provedeních. Vyberte ty vhodné pro vaši dílnu, výrobu nebo zajištění kvality.

Stejně tak různorodé jako požadavky na elektrická zařízení na měření délek jsou i jejich aplikace. Zde jsou požadovány maximální spolehlivost a přesnost a co nejjednodušší ovládání.

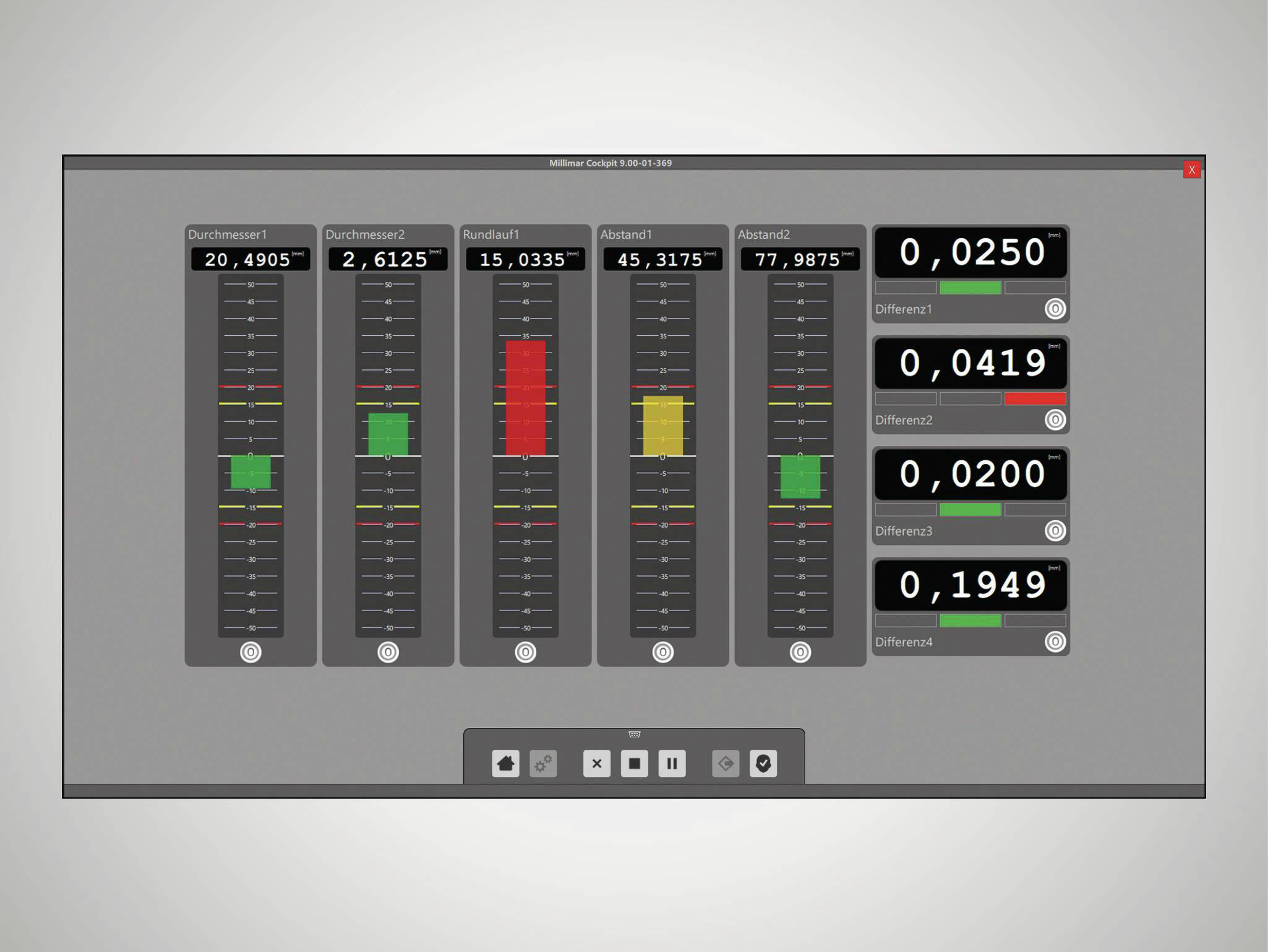

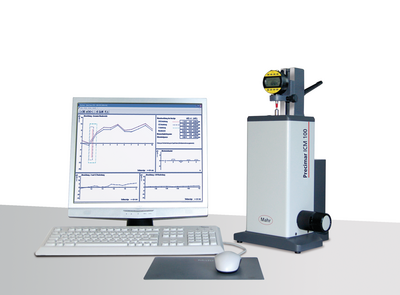

Stejně tak různorodé jako požadavky na elektrická zařízení na měření délek jsou i jejich aplikace. Zde jsou požadovány maximální spolehlivost a přesnost a co nejjednodušší ovládání. Kompaktní a sloupová měřicí zařízení Millimar tyto požadavky uspokojují.

Přístroje na měření délek Millimar jsou kompaktní, robustní a snadno použitelné. Jsou to univerzálně použitelná vyhodnocovací a zobrazovací zařízení pro měřicí úlohy se složitostí zvládnutelnou ve výrobní oblasti a měřicí laboratoři.

Díky široké škále možných kombinací modulů a softwaru máte příležitost navrhnout své pracovní prostředí a nástroje individuálněji než kdykoli předtím.

Chytrý a univerzálně použitelný software pro komplexní měřicí úlohy ve výrobním prostředí

Snímače naměřených hodnot Millimar jsou součásti měřicího řetězce s největším vlivem. Její vlastnosti určují kvalitu celého měření. Podle případu použití se pro toto nabízejí různé technologie. Na příklad indukční měřicí snímače Millimar: Robustní v konstrukci, flexibilní v aplikace a atraktivní z hlediska ceny.

Bez ohledu na to, zda se jedná o měření tloušťky, rovnoměrný rotační pohyb nebo soustřednost: pomocí indukčních snímačů zaznamenáte naměřené hodnoty a odchylky bez ohledu na odchylky tvaru, uložení nebo rotačního pohybu. Jejich velkou výhodou je velký rozsah linearity a relativní necitlivost na rušení. Snímače se používají hlavně pro srovnávací měření ve výrobě; konkrétní úkoly senzoru se mohou lišit.

Pneumatická zařízení na měření délek se vyznačují vysokou přesností a dlouhodobou stabilitou. Díky bezdotykovému měření měřicími tryskami nedochází k poškození obrobků. Spolehlivé měření i nevyčištěného, naolejovaného, namazaného nebo lapovací pastou potřeného obrobku je možné bez problémů, protože měřicí body jsou čištěny měřicím vzduchem.

Přístroje na měření délek Millimar jsou kompaktní, robustní a snadno použitelné. Jsou to univerzálně použitelná zobrazovací a vyhodnocovací zařízení pro měřicí úlohy se složitostí zvládnutelnou ve výrobní oblasti.

Výsledky měření se zobrazují na 101 trojbarevných světelných diodách, které jsou snadno čitelné i na dálku. Při překročení programovatelné výstražné hranice a hranice tolerance dojde vždy ke změně barvy segmentů ze zelené na žlutou, resp. červenou.

Pneumatická měřicí zařízení Millimar rychle a přesně zjistí odchylky rozměrů. V průběhu mnoha let se již osvědčila jako vysoce kvalitní pneumatické přístroje na měření délek v prostředí průmyslové výroby i měřicí laboratoře.

Když má měření a vyhodnocení probíhat mobilně.

Bezdotykové měření s pneumatickými měřicími kroužky, bez poškození obrobků.

Přizpůsobte měřicí pracoviště své měřicí úloze, s příslušenstvím pro pneumatickou měřicí techniku.

Důvěřujte nastavovacím etalonům Mahr - protože jsou základem pro přesné výsledky měření

Nastavení pneumatických měřicích zařízení (měřicích kroužků s tryskami). Pečlivě kalené, žíhané, broušené a leštěné.

Nastavení pneumatických měřicích zařízení (měřicích trnů s tryskami). Pečlivě kalené, žíhané, broušené a leštěné.

Chcete posunout vaše měření na nejvyšší úroveň? Proto je zde Digimar!

K orýsování a značení obrobků v dílenském prostředí. Snadné měření výšek a vzdáleností.

Praktické režimy a možnosti měření: Digimar 814 C usnadňuje typické měřicí úkony

Ovládání dotykem, ergonomická manipulace a široká škála možností vyhodnocení: To je charakteristické pro výškoměr Digimar 816 CLT.

Ovládání dotykem, ergonomická manipulace a široká škála možností vyhodnocení: To znamená výškoměr Digimar 817 CLT.

Ovládání dotykem, ergonomická manipulace a široká škála možností vyhodnocení: To znamená výškoměr Digimar 817 CLT.

Měřicí technika na přesné měření délek znamená techniku měření rozměrů s nejvyšší přesností, a to pomocí absolutních i relativních měření.

Univerzální, snadno použitelná zařízení pro měření délky a nastavovací zařízení pro výrobu

Univerzální, snadno použitelná zařízení pro měření délky a nastavovací zařízení pro výrobu

Na základě své široké palety produktů od jednoduché zkušebny koncových měrek, plně automatické zkušebny číselníkových úchylkoměrů a zařízení ULM až k ultra-přesným a částečně automatizovaným měřicím strojům CiM Universal nabízí společnost Mahr vždy praxí ověřené řešení pro výrobu, měřicí a kalibrační laboratoře. Jinak řečeno: Měřicí technika s nejvyšší přesností při maximálně efektivních měřicích procesech

Ať už klasická zařízení ULM nebo motorizovaná zařízení PLM a CiM. Univerzální délkoměry umožňují uživatelsky snadné, rychlé a bezpečné měření při nejnižší možné nejistotě výsledků.

Částečně automatizovaná a plně automatizovaná kontrola číselníkových úchylkoměrů, páčkových úchylkoměrů, indikátorů a snímačů - efektivně a přesně.

Částečně automatizovaná a plně automatizovaná kontrola číselníkových úchylkoměrů, páčkových úchylkoměrů, indikátorů a snímačů - efektivně a přesně.

Ruční testování úchylkoměrů, páčkových úchylkoměrů a přesných úchylkoměrů – jednoduché a přesné

Důvěřujte zkušebním stojanům na koncové měrky Mahr - protože jsou základem pro přesné zkoušení vašich etalonů

Mikroskopy se používají téměř ve všech průmyslových odvětvích k rychlé kontrole vzdáleností, poloměrů a úhlů. Ať už v laboratoři nebo v blízkosti výroby.

Pro rychlé vyhodnocení geometrických prvků

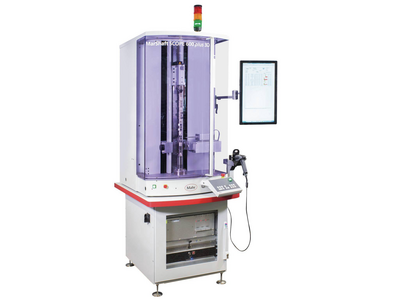

Technika na měření struktury povrchu pro průmysl a výzkum

Technika na měření struktury povrchu pro průmysl a výzkum

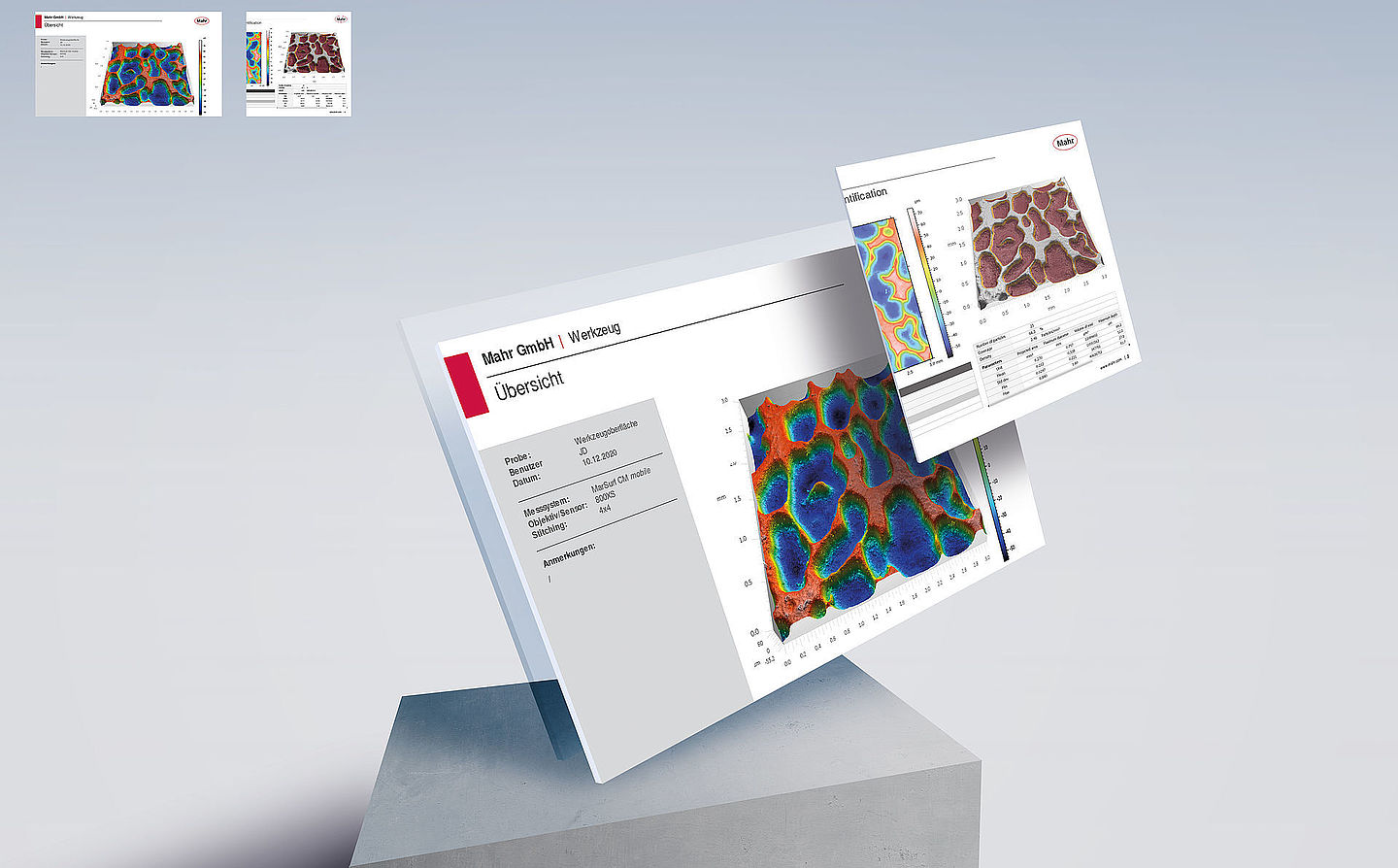

Strukturované funkční povrchy s úzkými tolerancemi vyžadují vysoce přesné měřicí systémy, které plošně zaznamenají topografii obrobku nebo předmětu během krátké doby.

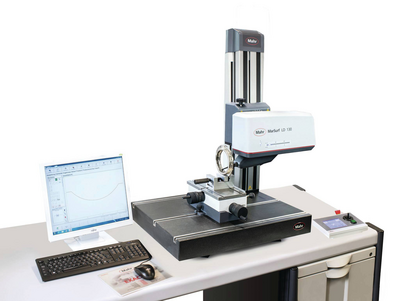

Technika měření kontur se používá k určení hrubých odchylek tvaru.

Přesné měření obrysů pomocí optických měřicích zařízení

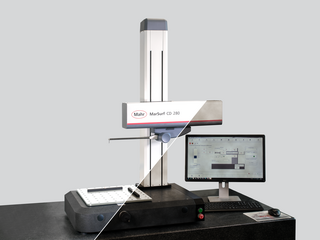

Kombinace měření kontury a drsnosti: Profesionální pro všechny případy

Kombinace měření kontury a drsnosti: Profesionální pro všechny případy

2D/3D měření kontur i drsnosti podle ISO 25178 / ISO 4287

Technika na 3D měření povrchů pro průmysl a výzkum

Měřte kdekoli s mobilními měřicími zařízeními!

Měřicí stanice pro měření vysoce přesné optiky

Když standard již není dostatečný: Individuální řešení na přání zákazníků

Strukturované funkční povrchy s úzkými tolerancemi vyžadují vysoce přesné měřicí systémy, které plošně zaznamenají topografii obrobku nebo předmětu během krátké doby.

Mnohostranné a výkonné na měřicím pracovišti a v laboratoři

Kombinace měření kontury a drsnosti: Profesionální pro všechny případy

Taktilní měřicí stanice pro měření kontury a drsnosti

2D/3D měření kontury a drsnosti podle ISO 25178 / ISO 4287

Technika na 3D měření povrchů pro průmysl a výzkum

Měřte kdekoli s mobilními měřicími zařízeními!

Mobilní technika na 3D měření povrchů k

použití na místě

S mobilními měřicími zařízeními měříte vždy přesně tam, kde jsou zapotřebí výsledky.

Měřicí stanice pro měření vysoce citlivé optiky

Když standard již není dostatečný: Individuální řešení na přání zákazníků

Vyzkoušejte vynikající funkce v kombinaci s extrémní flexibilitou velikosti obrobků a zvyšte svou produktivitu ve výrobním prostředí.

Flexibilní měření obrobků upnutých mezi středicími hroty

Velmi rychlá matrix-kamera s vysokým rozlišením pro měření velkého počtu charakteristik rotačně symetrických obrobků.

Rychlá optická maticová kamera v kombinaci s vysoce přesnými dotykovými sondami pro měření velkého počtu prvků na rotačně symetrických obrobcích.

Flexibilní možnosti upínání a vysoce přesné vyrovnání pomocí plně automatického centrovacího a naklápěcího stolu

Velmi rychlá matrix-kamera s vysokým rozlišením pro měření velkého počtu charakteristik rotačně symetrických obrobků. Přidání plně automatického středicího a naklápěcího stolu pro extrémně rychlé mechanické vyrovnání a flexibilní možnosti upínání.

Rychlá optická matrix kamera v kombinaci s vysoce přesnými dotykovými sondami pro měření velkého počtu charakteristik na rotačně symetrických obrobcích. Přidání plně automatického středicího a naklápěcího stolu pro extrémně rychlé mechanické vyrovnání, flexibilní možnosti upínání a např. vnitřní měření.

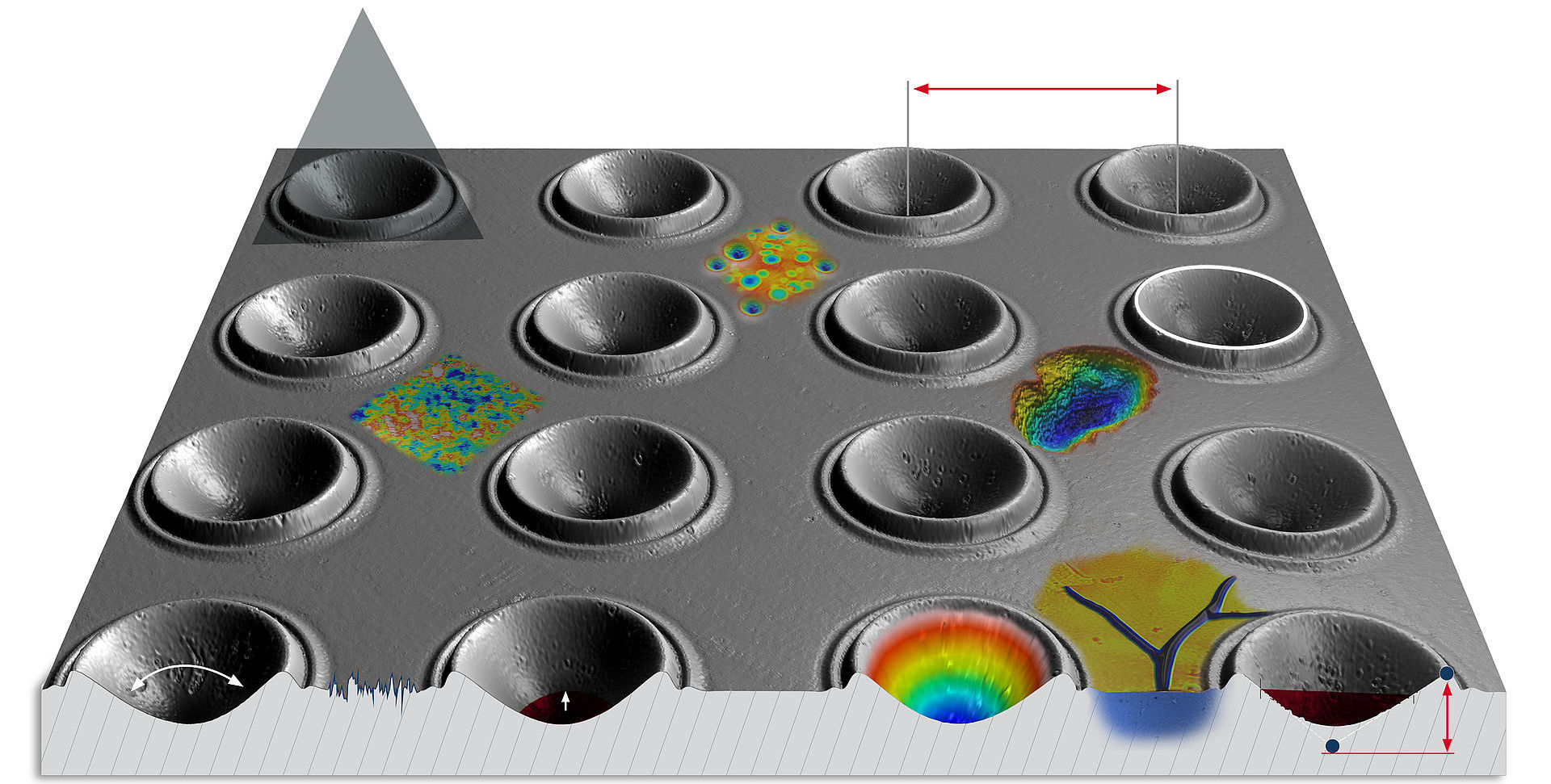

Systémy pro měření úchylek tvaru a polohy, jako je kruhovitost, rovinnost, přímost nebo souosost. Od manuálních po plně automatizované.

Měřte snadno charakteristiky, jako je kruhovitost, přímost a obvodové házení, s vysokou přesností a za příznivou cenu. Naše ruční přístroje na měření tvarů jsou vhodné jak pro měřicí laboratoře, tak i pro měření v blízkosti výroby.

S našimi automatickými systémy měření tvarů snížíte procesní náklady, aniž by to zásadně navýšilo náklady na kontroly – díky stabilním, inovativním zařízením s vysokou mírou automatizace, flexibility a přesnosti.

měřicí technika

Vyzkoušejte vynikající funkce v kombinaci s extrémní flexibilitou velikosti obrobků a zvyšte svou produktivitu ve výrobním prostředí.

Flexibilní měření obrobků upnutých mezi středicími hroty

Flexibilní možnosti upínání a vysoce přesné vyrovnání pomocí plně automatického centrovacího a naklápěcího stolu

Optické a taktilní systémy na měření hřídelí pro Vložka v drsném výrobním prostředí. Kompletní měření všech běžných rotačně symetrických obrobků.

.Univerzální, plně automatické a robustní optické přístroje pro měření hřídelů pro použití v náročných výrobních podmínkách.

Opticko-taktilní hřídelové snímače pro použití v drsném výrobním prostředí. Kompletní měření všech běžných rotačně symetrických obrobků.

měřicí technika

Vyzkoušejte vynikající funkce v kombinaci s extrémní flexibilitou velikosti obrobků a zvyšte svou produktivitu ve výrobním prostředí.

Flexibilní měření obrobků upnutých mezi středicími hroty

Flexibilní možnosti upínání a vysoce přesné vyrovnání pomocí plně automatického centrovacího a naklápěcího stolu

Široká škála technologií a produktů pro rychlé a bezkontaktní zaznamenávání povrchů a geometrií.

Pro rychlé vyhodnocení geometrických prvků

Stanovení drsnosti, kontury a mnoha dalších parametrů povrchu.

Technika na měření struktury povrchu pro průmysl a výzkum

Minimální drsnost s přesností na nanometr

Optická analýza topografií povrchů a geometrií

Technika na měření struktury povrchu pro průmysl a výzkum

Technika na měření struktury povrchu pro průmysl a výzkum

Repasované systémy v osvědčené kvalitě Mahr

MarTool calipers are characterized by essential technology and easy operation.

All theese in good professional quality, at the best price!

16 E -- Simple with essential features

16 ES -- High quality with essential features

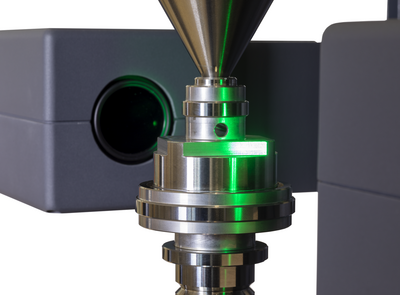

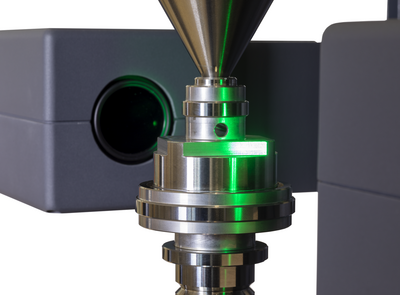

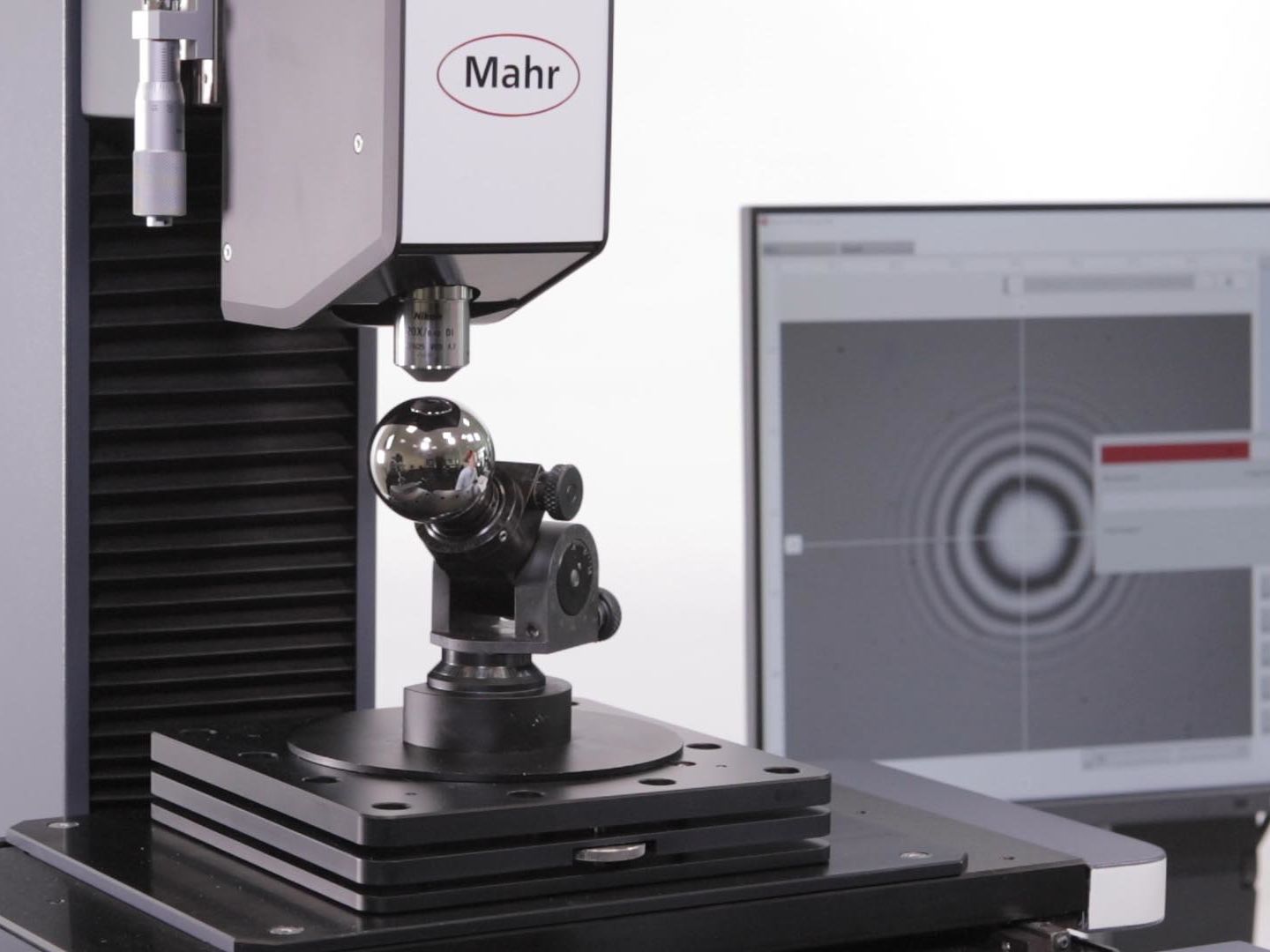

Minimal roughness down to the nanometer

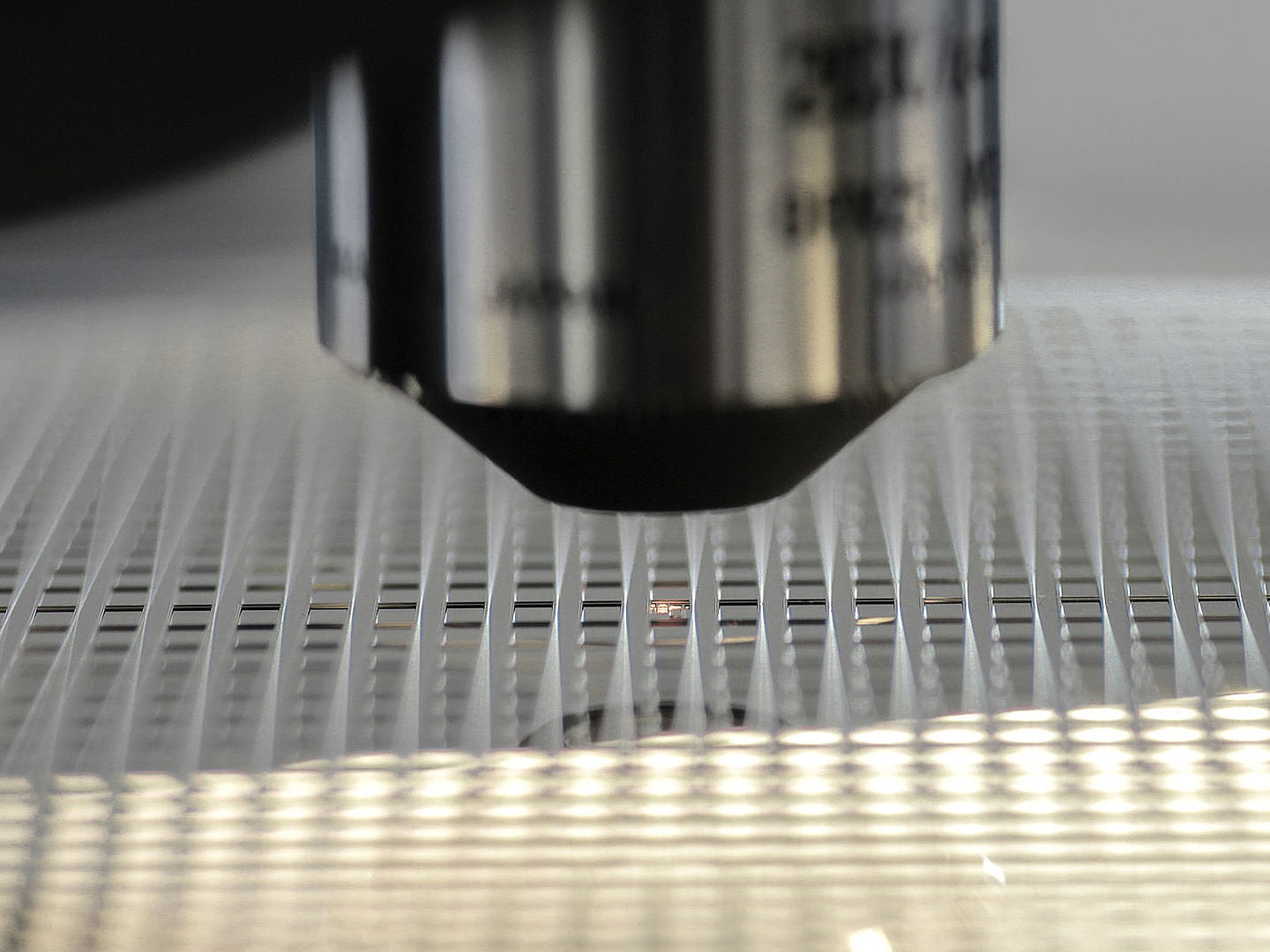

In medical engineering, semiconductor, optical and other branches of industry, extremely smooth surfaces with specific properties are required more and more frequently. This is where the new Mahr White Light Interferometer steps in.

ICA Technology

The new ICA technology, combines the good features of previous methods such as PSI and VSI in a single, large application area. The innovative algorithm determines the statistical correlogram of the surface and uses this for evaluating the measured data.

- Use of phase information and amplitude

- No averaging of the measurement data

- Maximum stability and high accuracy

Minimal noise of only 80 picometers

ICA enables the exact determination while minimizing noise at the same time, thus ensuring very high data quality. Due to this high signal-to-noise ratio, the Mahr technology reaches the quality level of a PSI with only 80 picometers (STR/Surface Topography Repeatability), but performs with a better stability and higher reliability.

Whether manual or automated

The MarSurf WI series portfolio comprises three devices with specific benefits for customers.

- WI 50 M: manual all-round entry-level solution for demanding measurement tasks

- WI 50: high-precision measuring tool for research and quality assurance

- WI 100: serial measurements without user influence and broadest flexibility

Large positioning volume

Both the MarSurf WI 50M and the WI 100 devices have an extended working range in XY and, more importantly, the Z direction for large sample volumes. Example WI 100: Simply move the additional manual Z axis upwards using the adjustment on the side to measure XXL components.

The motorized high-end device MarSurf WI 100 is characterized by an extended working range in the XYZ direction - simply use the lateral adjustment to move the the additional manual Z axis. This means that components can be measured easily while staying clamped in their specific mount.

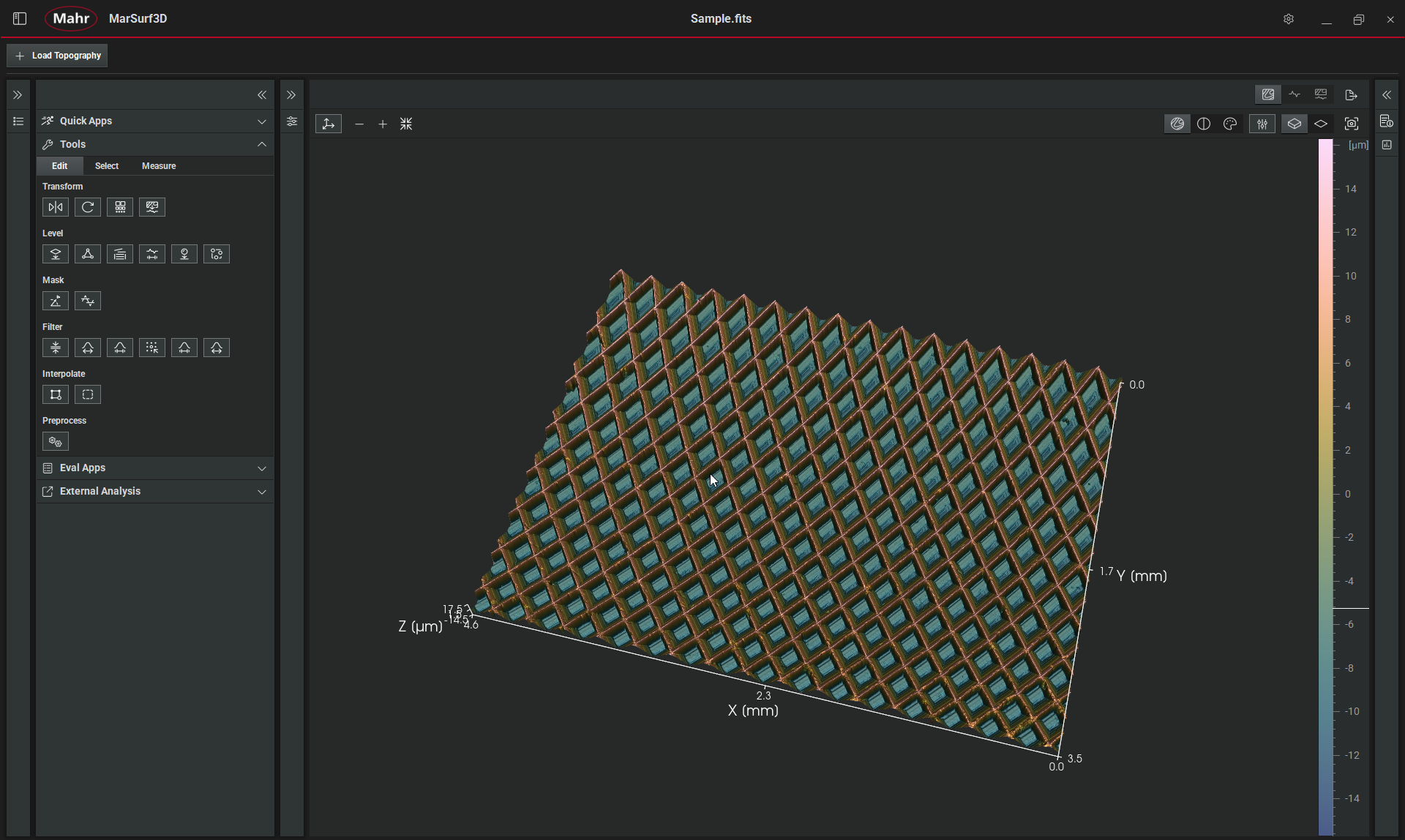

Intuitive user software

Measure, display, evaluate: With the comprehensive software solutions from Mahr, this can be done intuitively and effectively. One software for interferometers, confocal microscopes and profilometers. Further advantages:

- Fast and reliable measurements thanks to intuitive operation

- Clear and flexible visualization of results

- Automation options for efficient series measurements

MarSurf 3D software has been in use and established for many years. Popular features for easy measurement are:

- Snapshot technology to acquire measurements with just a few clicks

- Pre-scan function for quick selection of the measurement area

- Auto-intensity and Auto-Range for optimum usability

- Template function for repetitive measurements

- Multi-spot tool to perform multiple measurements automatically

Comprehensive display of results and easy documentation for roughness, waviness and much more:

- High-quality 3D display for a quick overview

- 2D and 3D analysis according to common standards (ISO 4287, 25178, 13565 ...)

- Geometry, volume, contour, CAD comparison

- Simple documentation with on-the-fly or subsequent analysis option in the report

Automate measurements and evaluations with MarSurf Automation Software

- User-independent serial measurements

- Industrial suitability

- Different measurement tasks and evaluations programmable per sample in a single measurement recipe

- Protocol generation, SPC control, QS-Stat output

One philosophy

No matter which Mahr measuring system you choose: You probably already know the software that goes with it. For all systems in the MarSurf 3D series, Mahr relies on the same clearly structured software design that has proven itself in practice many times over.

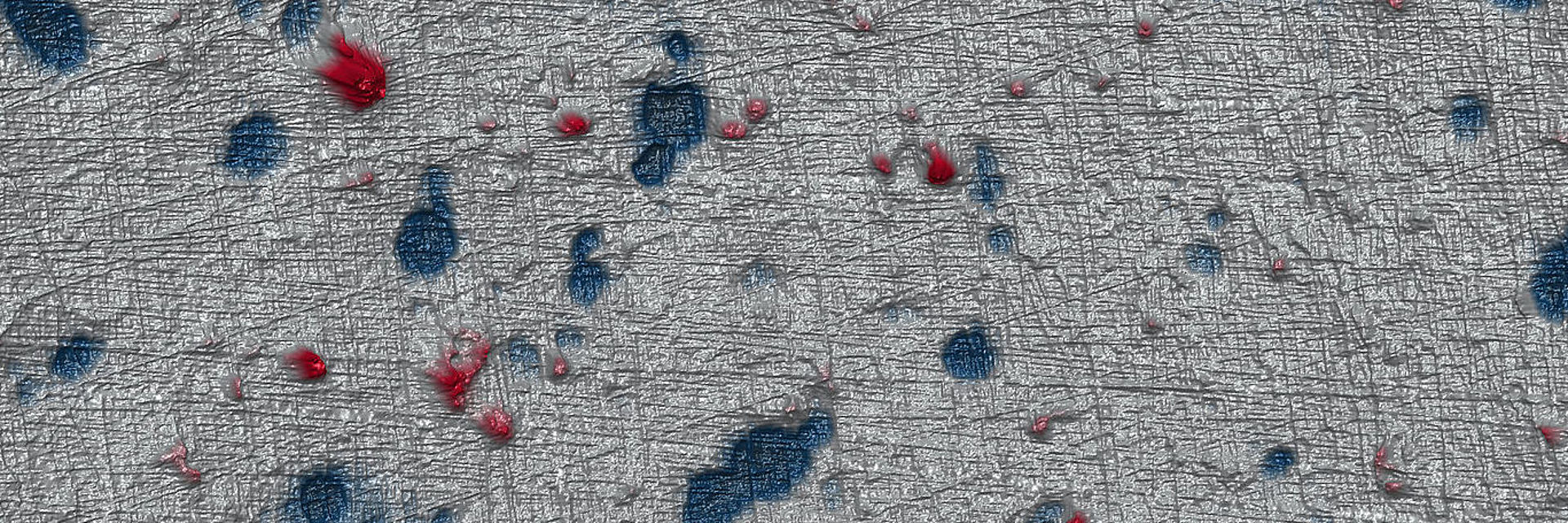

The application

The performance of components is determined increasingly by their surface properties. This is valid for shape deviations and roughness as well as waviness or geometric features. Our systems are used in the following industries: optics, medical technology, semiconductor industry, surface technology, material science, microsystems technology and many more.

Detection and classification of particles, grains, furrows, textures, hills and valleys

Nächster SpotExtensive horizontal distance measurements (x;y), angular positions and inclinations

Nächster SpotProfile roughness according to ISO 4287, ISO 13565, ASME B46.1, ISO 12085, VDA, SEP or MBN standards

Nächster SpotShape deviation of planar contours, nominal/actual comparison against CAD data, roundness evaluation according to ISO 12181

Nächster SpotDetermination of the flatness of a total or partial surface e.g. according to ISO 12781

Nächster SpotDistance measurements (z), determination of maximum and average heights and position differences

Nächster SpotLive views or photosimulated representations in the evaluations as well as 3D views

Nächster SpotDetermination of radii, circles, circle sections as well as angle determination incl. evaluation of half or total angles

Nächster SpotLine deviations from a nominal contour and straightness parameters according to ISO 12780

Nächster SpotDirect layer thickness determination for transparent surfaces, for opaque surfaces the layer thickness is determined via a step height analysis

Nächster SpotCalculation of surface areas for peaks and troughs and determination of maximum elevations/depressions

Nächster SpotThe new Mahr white light interferometers

The MarSurf WI 50 M is the manual entry-level solution for the new Mahr white light interferometry. The control is integrated in the stand, and the functional tilting stage and the manual x, y and z axes make adjustment and focusing easy for users. Further benefits are the compact design and large installation space, as well as an interesting price/performance ratio.

Our professional solutions for measuring in the nanometer range, the MarSurf WI 50 and WI 100, acquire 3D measurement data quickly and in just a few steps. Their HD stitching function ensures a consistently high resolution even for large measurement areas. The integrated collision detection provides safety in all directions - for the workpiece as well as for the device itself. The high-end MarSurf WI 100 can be equipped with an automation software for recurring measuring tasks.